2026 Newsletter

2026 Newsletter

PanLink provides real-time thermodynamic, kinetic,

and thermal-physical properties

Ensuring high-fidelity prediction of melt-pool geometry,

temperature profile, and microstructural evolution

Thermodynamic Modeler and Results Analyst

PanLink Simulation Engine: performs efficient,

reusable phase-equilibrium and property calculations

Courtesy of Quanliang Liu and Prof. Hyunseok Oh,

University of Wisconsin–Madison

Integrated and extendible modeling platform

Unified workspace and GUI

GUI or batch mode for HTC

Easy coupling with other ICME tools

Object-Oriented Design and Written in C++

Simple and Easy to Use API Functions

Flexible Materials Data Management

Customizable Table with Export Function

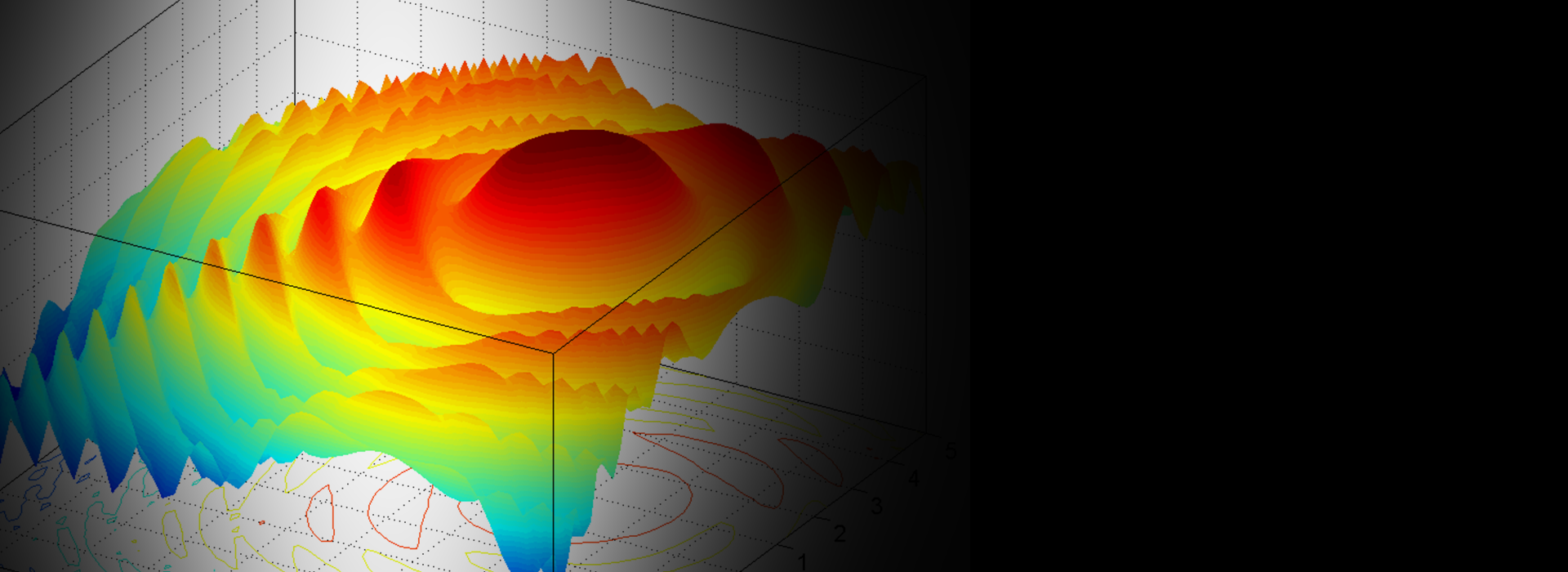

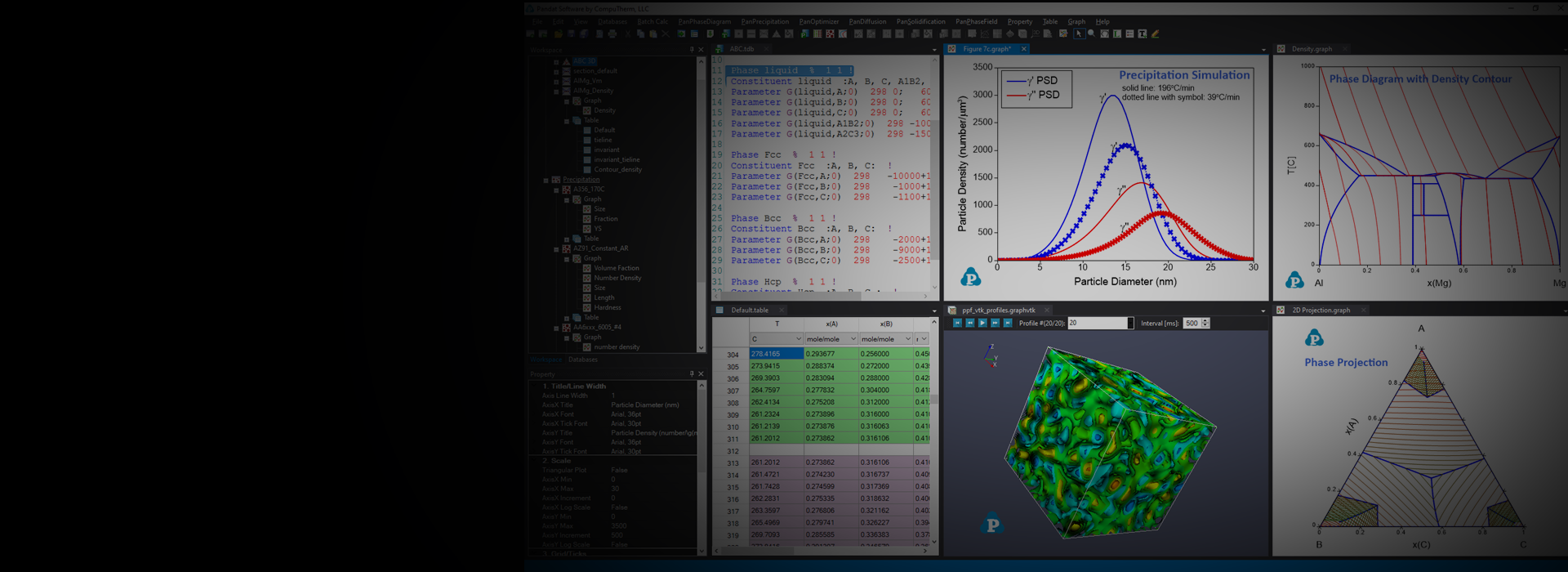

High Quality and Customizable Graph in 2D/3D

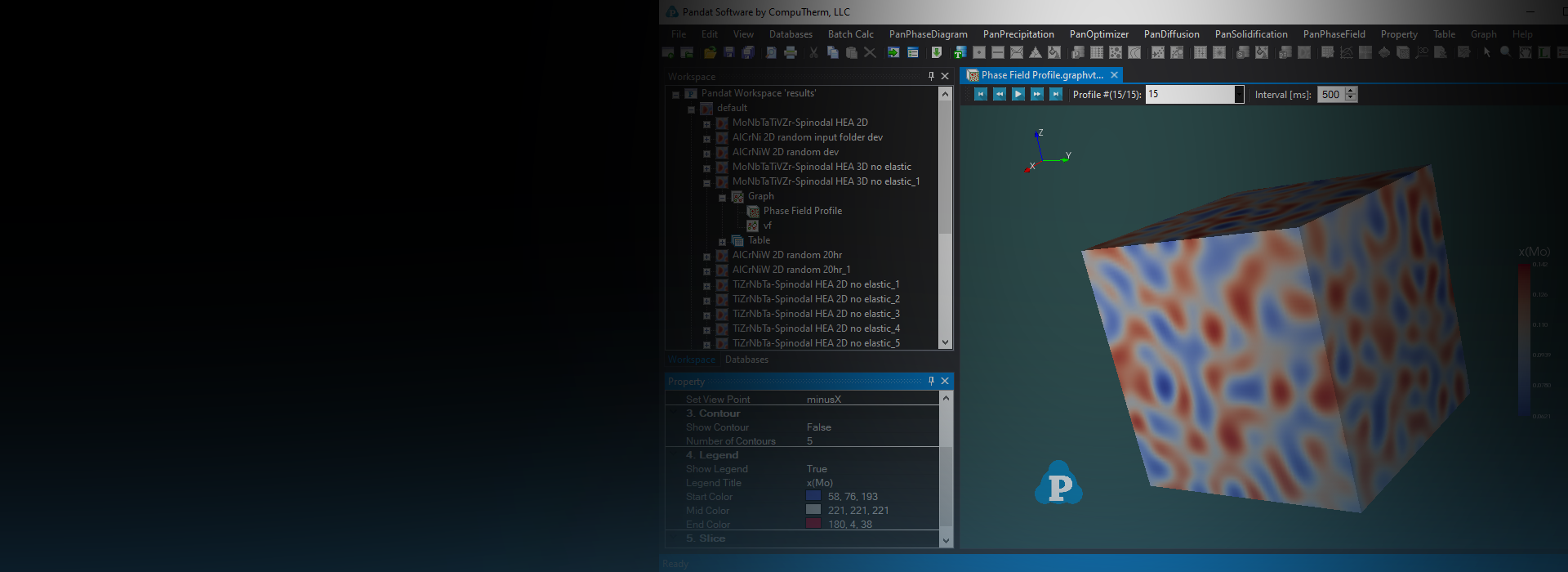

Pandat Software Modules

Pandat Software adopts modular design and enables users to easily switch between modules and perform various types of simulations in the same workspace.

- stable and metastable diagrams

- property contour diagrams

- thermodynamic properties

- chemical driving force

- material to material diagrams

- particle concurrent nucleation, growth and coarsening

- multi-phase co-precipitation

- precipitation and grain growth

- recrystallization and grain growth

- TTT and CCT curves

- diffusion couple

- homogenization

- carburization and decarburization

- particle dissolution

- Optimization of thermodynamic, kinetic and thermo-physical model parameters using experimental data

- solidification path

- back-diffusion in the solid

- dendrite arm coarsening

- micro-segregation

- solute trapping effect

- direct coupling with CALPHAD

- feasible for multi-component alloys

- open architecture for user’s model plugin