1

1

CompuTherm LLC – www.computherm.com

Types of Binary Phase Diagrams

• Isomorphous Systems

• Eutectic Systems

• Eutectoid Systems

• Peritectic Systems

• Peritectoid Systems

• Monotectic Systems

• Syntectic Systems

2

2

CompuTherm LLC – www.computherm.com

Isomorphous Systems

Isomorphous:

Two elements are completely soluble in each other in solid and

liquid states; substitutional solid state solution can be formed;

single type of crystal structure exists.

Hume-Rothery Rules:

(1) atoms have similar radii;

(2) both pure materials have same crystal structure;

(3) similar electronegativity (otherwise may form a compound

instead);

(4) solute should have higher valence.

Example:

Cu-Ni (slow cooling conditions), Mo-Nb, Mo-V, ...

3

3

CompuTherm LLC – www.computherm.com

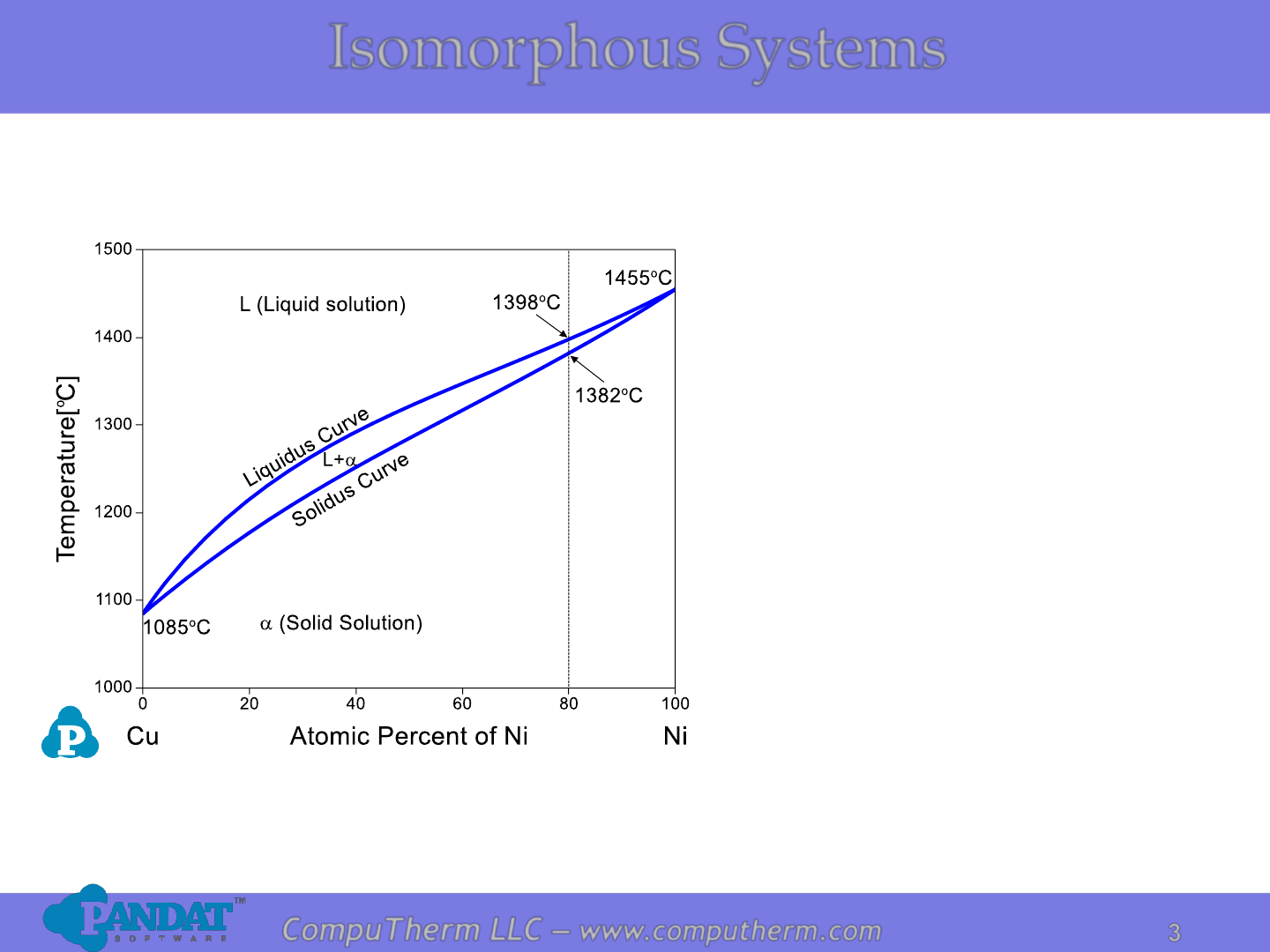

Isomorphous Systems

Information from this diagram:

• Pure Ni melts at 1455

o

C

• Pure Cu melts at 1085

o

C

• Pure component melts at a

fixed temperature, an alloy

melts in a temperature range.

• Cu-80at%Ni starts to melt at

1382

o

C (solidus), and becomes

complete liquid at 1398

o

C

(liquidus)

• Liquid and solid coexist

between the liquidus and

solidus temperatures

4

4

CompuTherm LLC – www.computherm.com

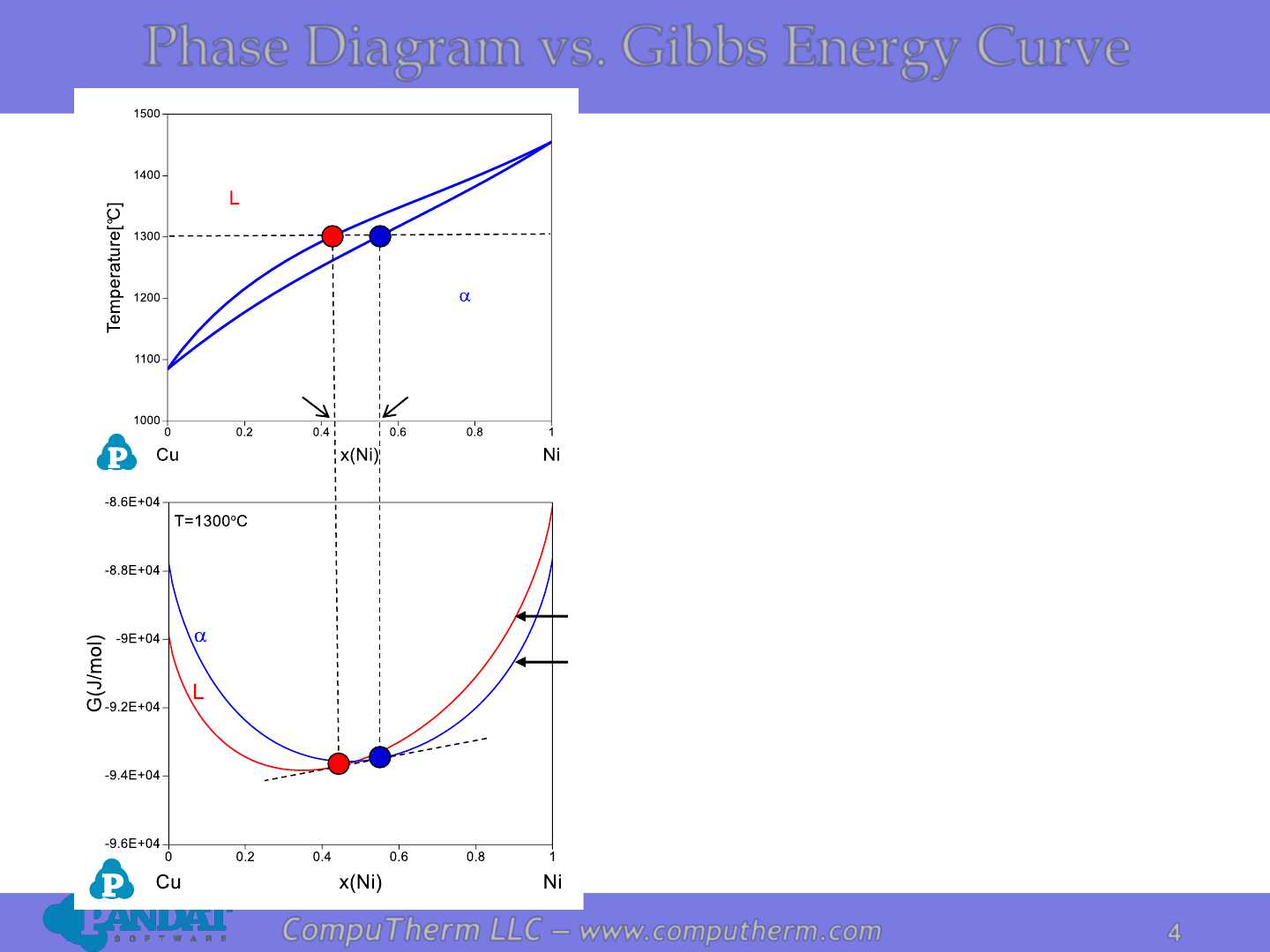

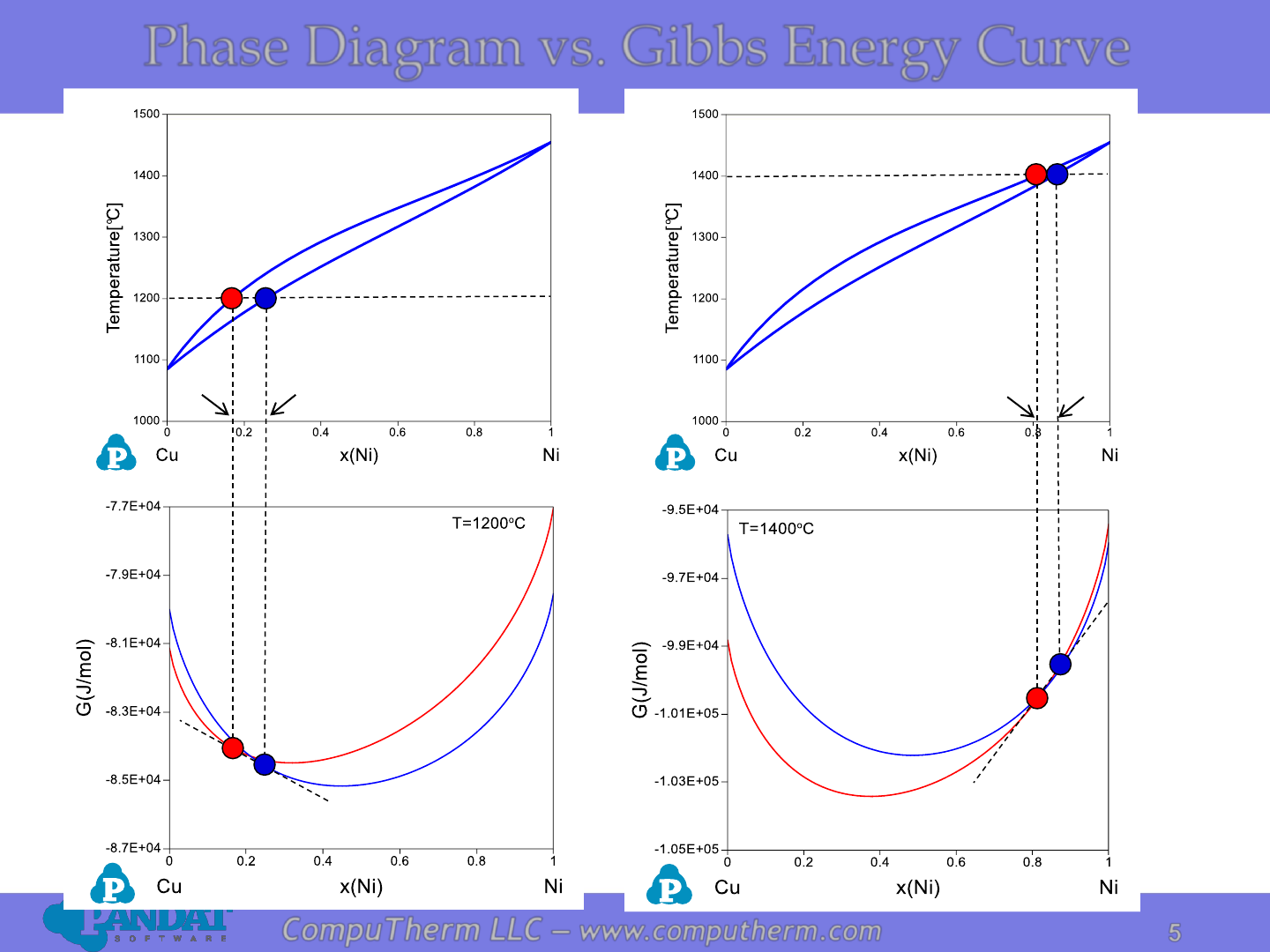

Information Obtained from both the Phase

Diagram and the G-x Diagram:

At the given temperature T=1300

o

C

1. On the left of x

L

, Liquid is most stable

2. On the right of x

a

, a phase is stable

3. Between x

L

and x

a

the two-phase mixture is

stable

x

L

x

a

( )

LL

B

L

A

L

B

L

B

L

A

L

A

L

B

L

B

L

A

L

A

L

xxxxxxRTGxGxG

++++= lnln

( )

aaaaaaaaaaaa

BABBAABBAA

xxxxxxRTGxGxG ++++= lnln

Phase Diagram vs. Gibbs Energy Curve

5

5

CompuTherm LLC – www.computherm.com

x

L

x

a

x

L

x

a

Phase Diagram vs. Gibbs Energy Curve

6

6

CompuTherm LLC – www.computherm.com

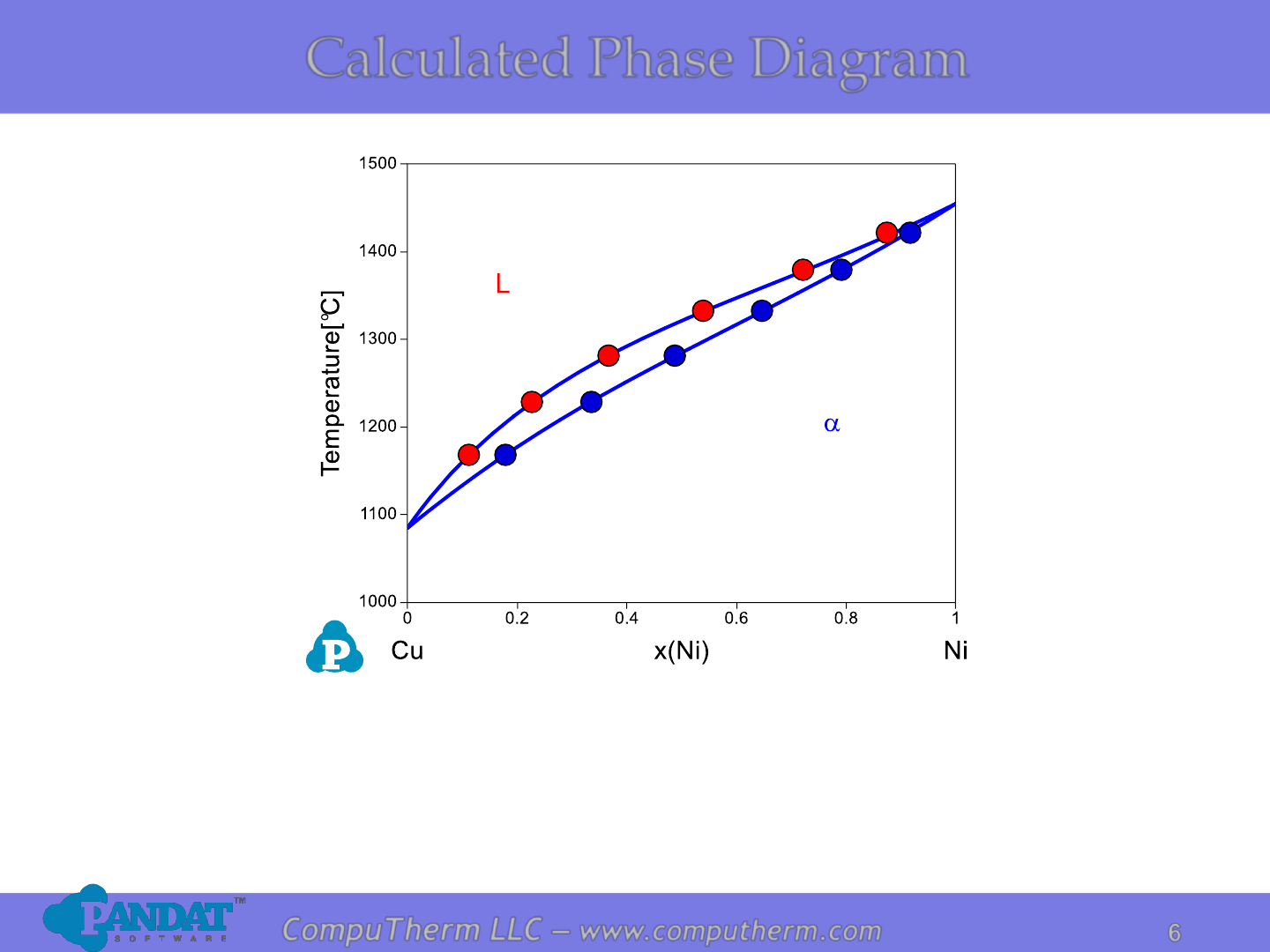

Details Refer to:

1. Database: Database_Isomorphous_Cu-Ni.tdb

2. Tutorial Video: Binary_Isomorphous

Calculated Phase Diagram

7

7

CompuTherm LLC – www.computherm.com

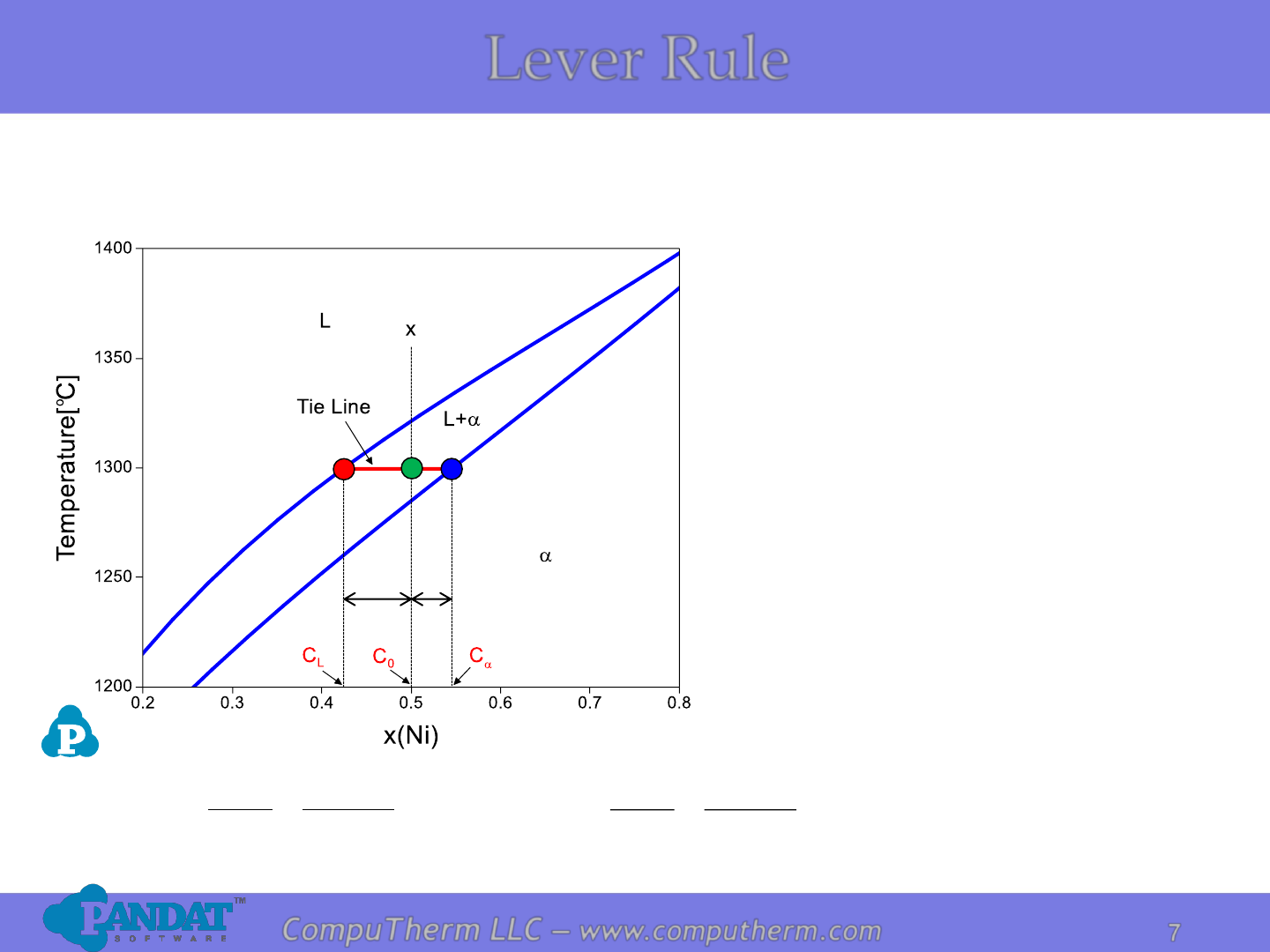

Finding the amounts of phases

in a two-phase region:

1. Locate composition and

temperature in diagram

2. In two-phase region draw the

tie line

3. Fraction of a phase is

determined by taking the

length of the tie line to the

phase boundary for the other

phase, and divided by the

total length of tie line

L

L

CC

CC

SR

S

F

−

−

=

+

=

a

a

0

L

L

CC

CC

SR

R

F

−

−

=

+

=

a

a

0

R

S

Lever Rule

8

8

CompuTherm LLC – www.computherm.com

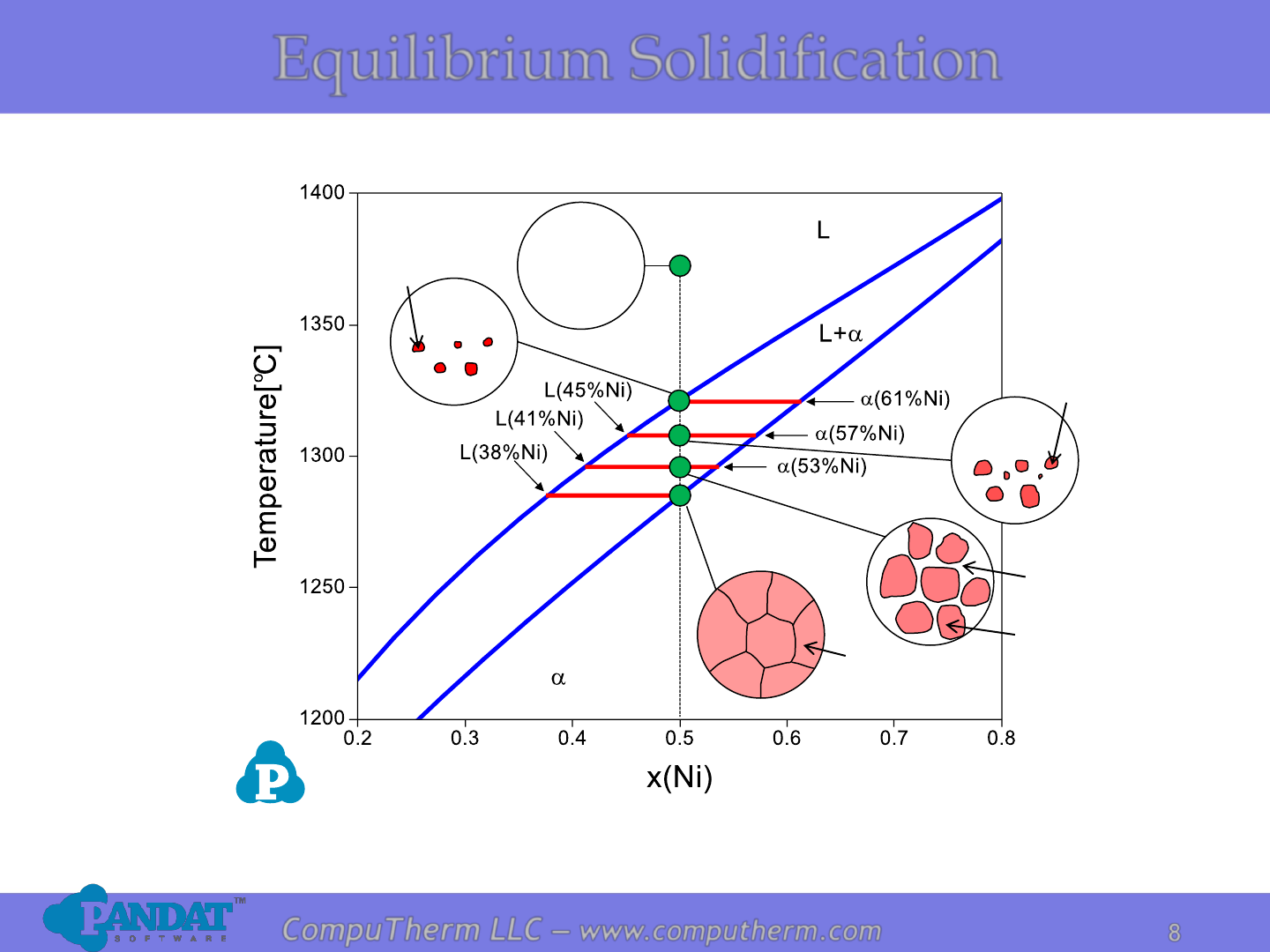

Equilibrium Solidification

L

(50%Ni)

a

(50%Ni)

L

(41%Ni)

a

(53%Ni)

L

(45%Ni)

a

(57%Ni)

L

(50%Ni)

a

(61%Ni)

9

9

CompuTherm LLC – www.computherm.com

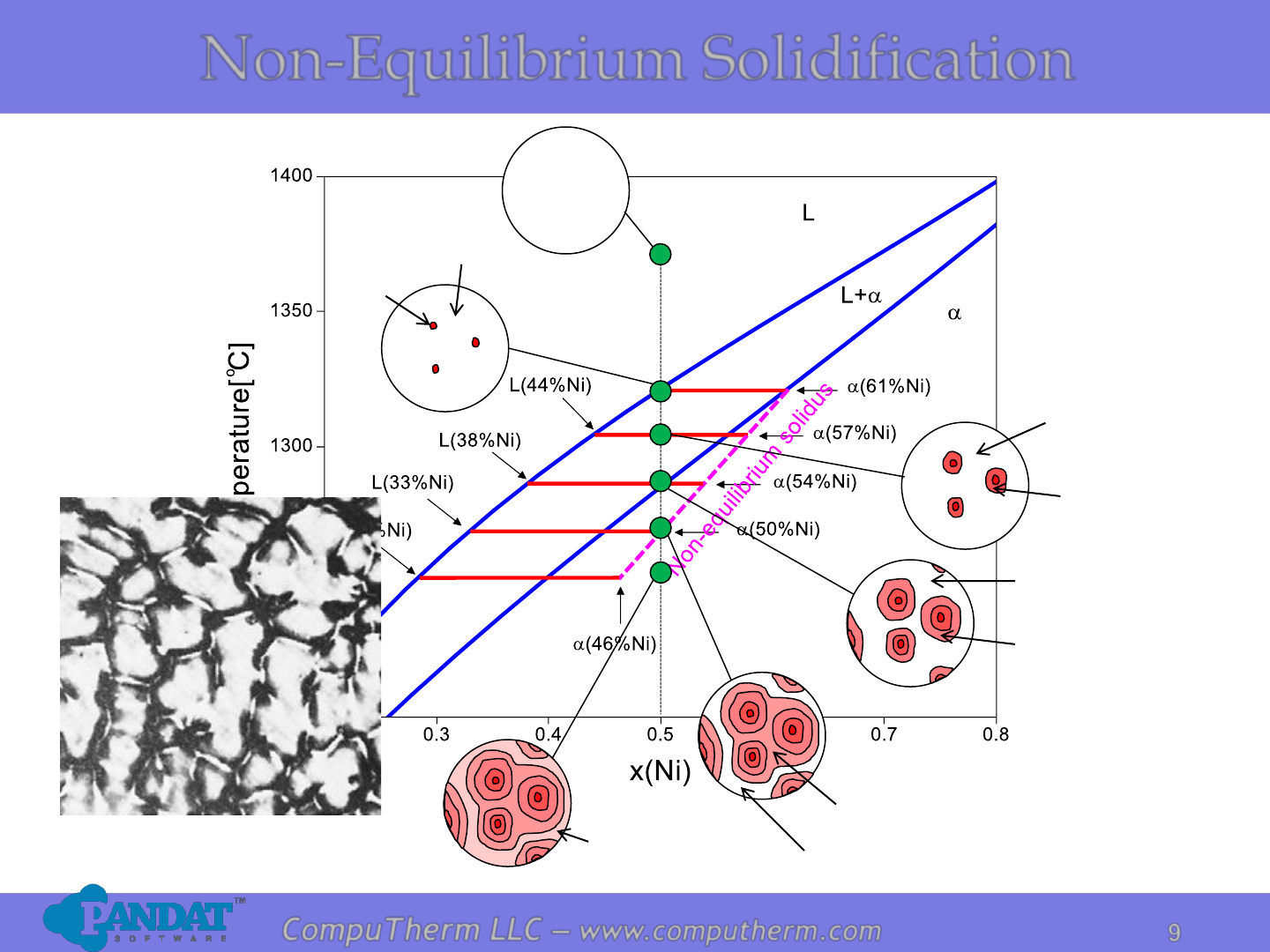

Non-Equilibrium Solidification

a

(61%Ni)

L

(50%Ni)

L

(44%Ni)

a

(57%Ni)

L

(33%Ni)

a

(50%Ni)

a

(46%Ni)

L

(38%Ni)

a

(54%Ni)

L

(50%Ni)

As-cast 70%Cu – 30%Ni alloy

showing a cored structure

Non-equilibrium

solidus due to

undercooling of the

liquid phase and

low diffusion in the

solid phase

10

10

CompuTherm LLC – www.computherm.com

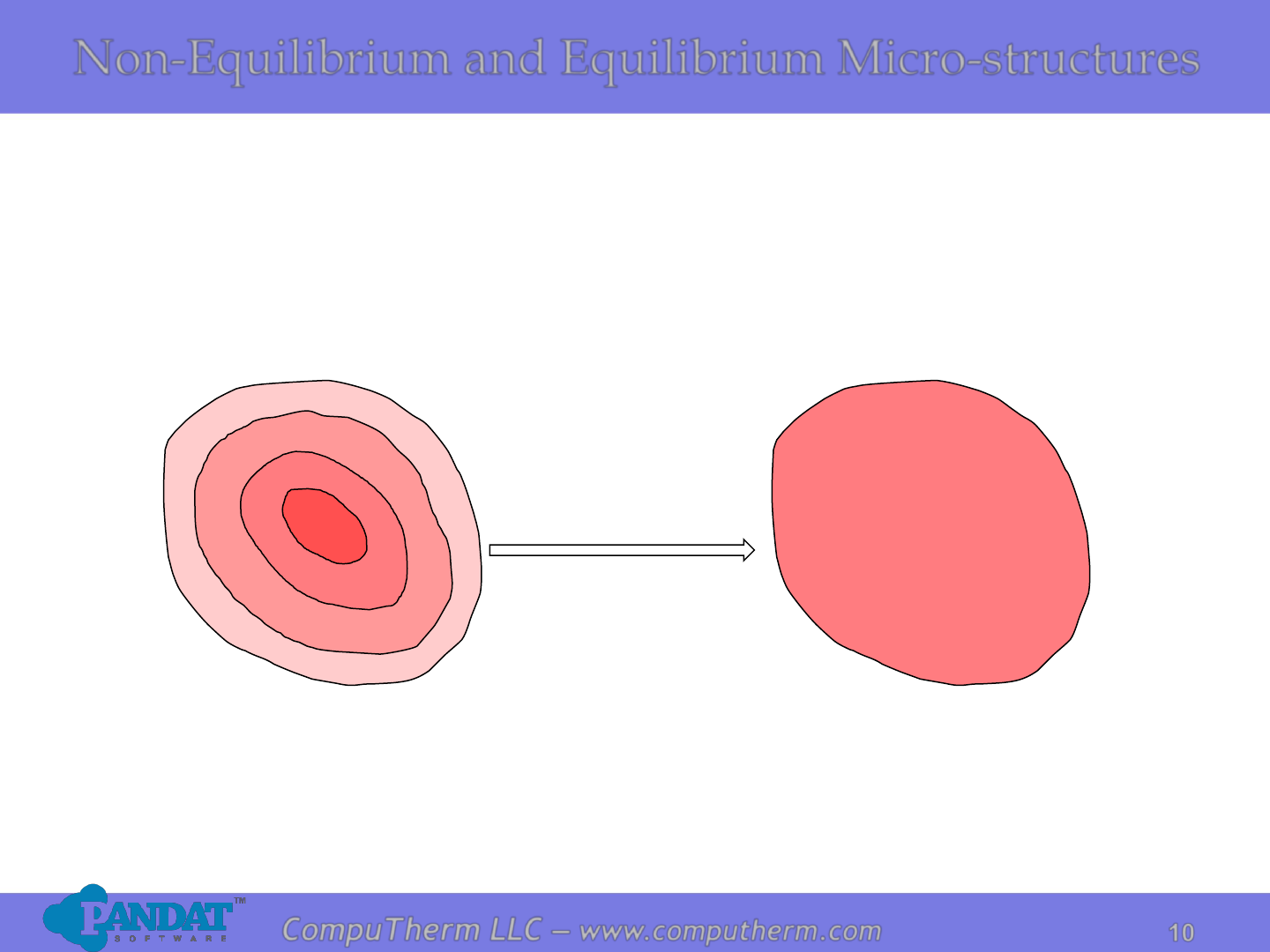

Non-Equilibrium and Equilibrium Micro-structures

Non-Equilibrium Structure

Fast cooling rate

C

a

changes during solidification

Equilibrium Structure

Very slow cooling rate

Uniform C

a

during solidification

Coring can be eliminated by means of a homogenization heat

treatment carried out at temperatures below the alloy’s solidus

Heat Treatment

11

11

CompuTherm LLC – www.computherm.com

Types of Binary Phase Diagrams

• Isomorphous Systems

• Eutectic Systems

• Eutectoid Systems

• Peritectic Systems

• Peritectoid Systems

• Monotectic Systems

• Syntectic Systems

12

12

CompuTherm LLC – www.computherm.com

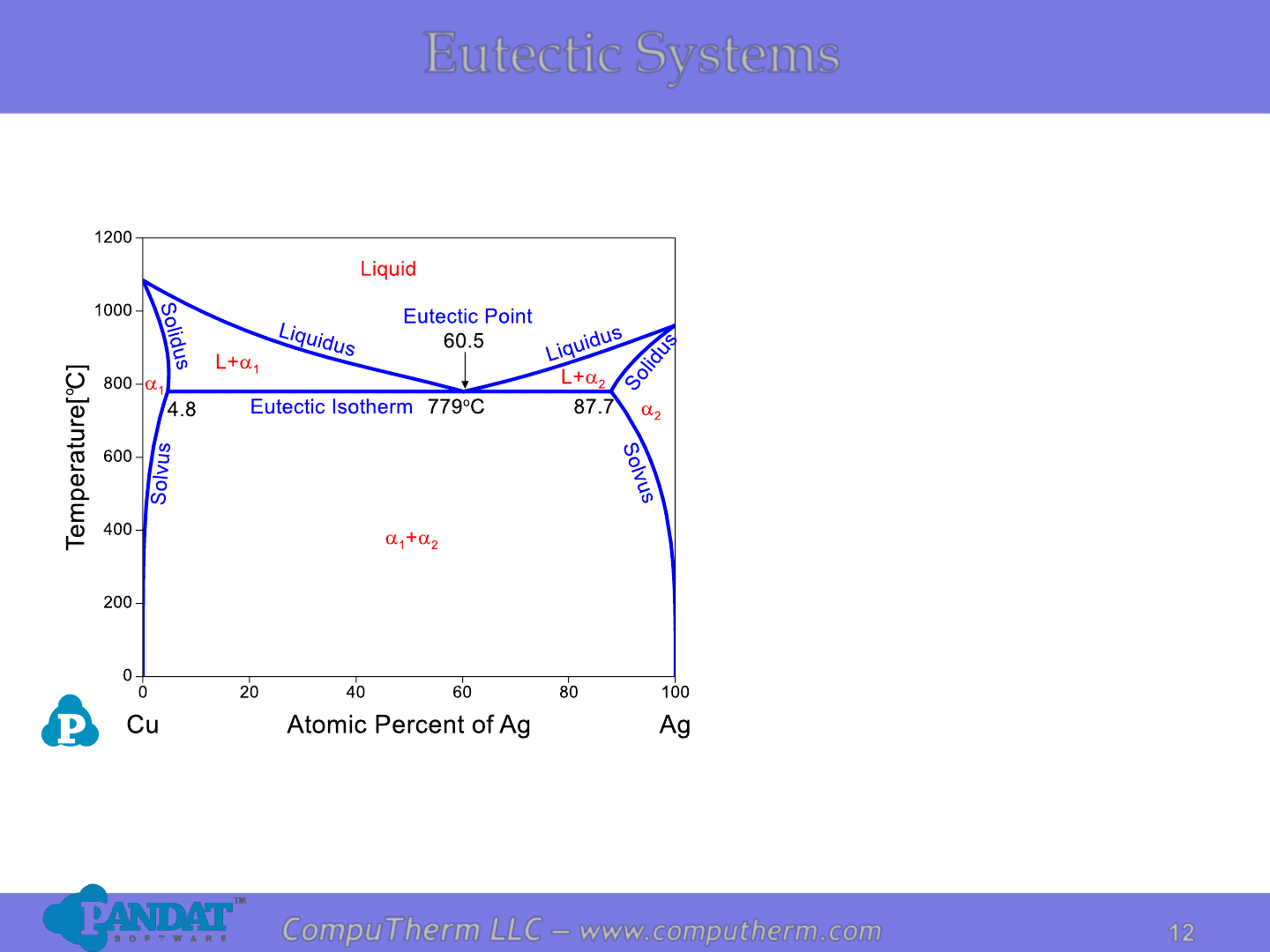

Eutectic Systems

Information from this diagram:

• Eutectic reaction occurs at

779

o

C and 60.5 at% Ag:

L ↔ a

1

+ a

2

.

• Alloy (4.8%<x

Ag

<87.7%) starts

to melt at eutectic reaction

temperature 779

o

C and

becomes complete liquid at

liquidus.

• Alloy (x

Ag

<4.8% or x

Ag

>87.7%)

transforms from two phases to

single phase when crossing

solvus from lower temperature,

starts to melt at solidus, and

becomes complete liquid at

liquidus.

13

13

CompuTherm LLC – www.computherm.com

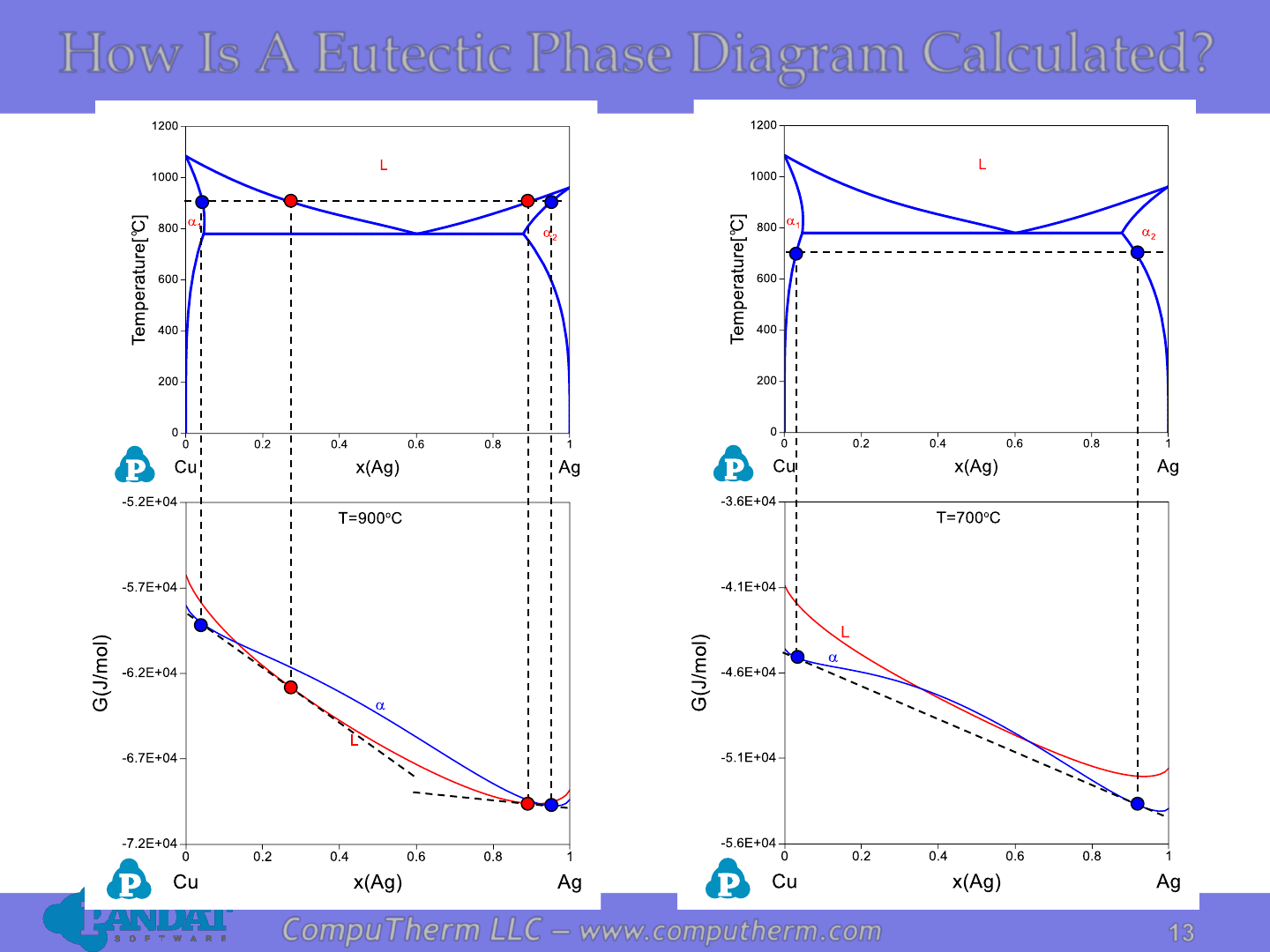

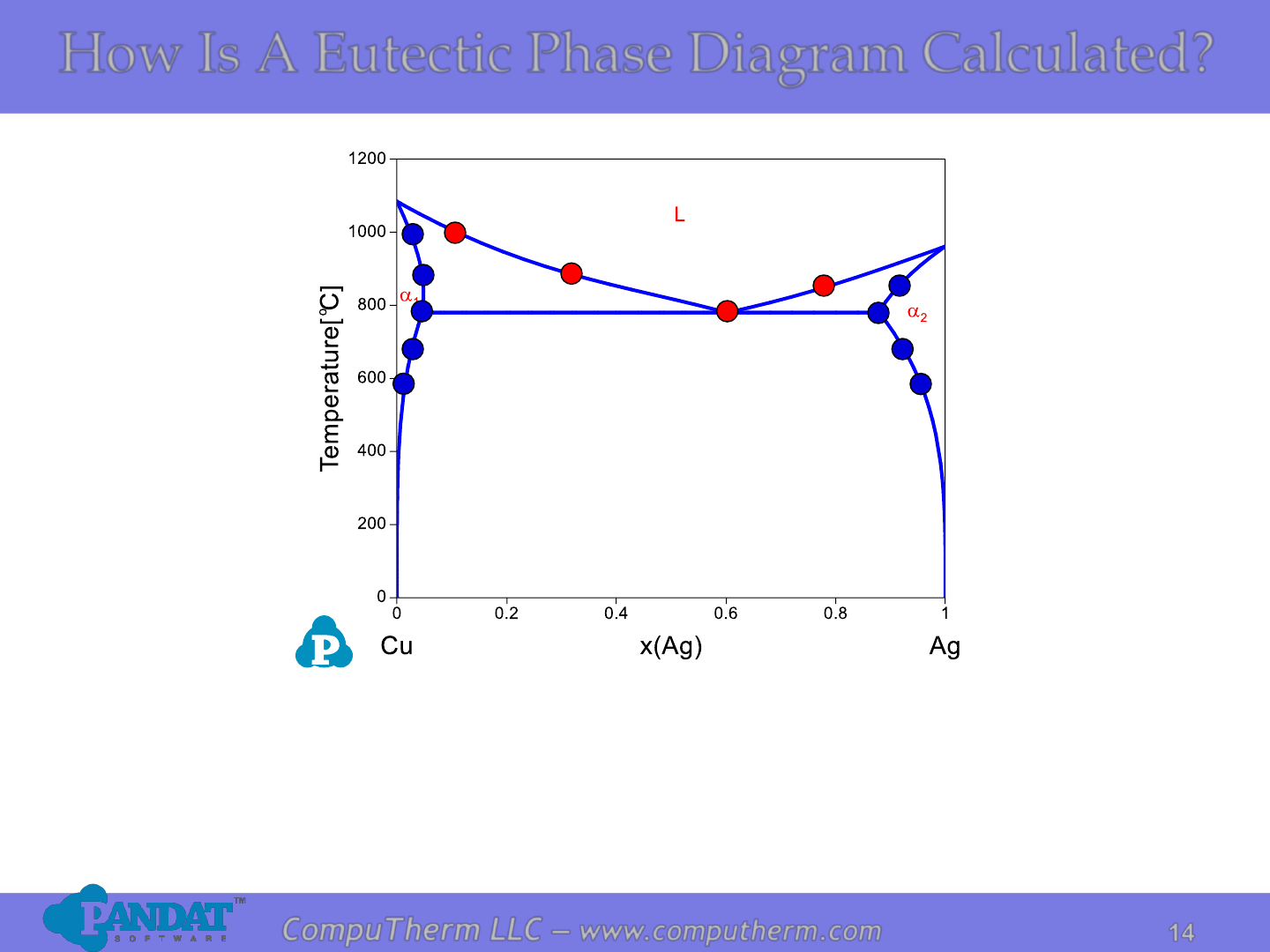

How Is A Eutectic Phase Diagram Calculated?

14

14

CompuTherm LLC – www.computherm.com

How Is A Eutectic Phase Diagram Calculated?

Details Refer to:

1. Database: Database_Eutectic_Cu-Ag.tdb

2. Tutorial Video: Binary_Eutectic

15

15

CompuTherm LLC – www.computherm.com

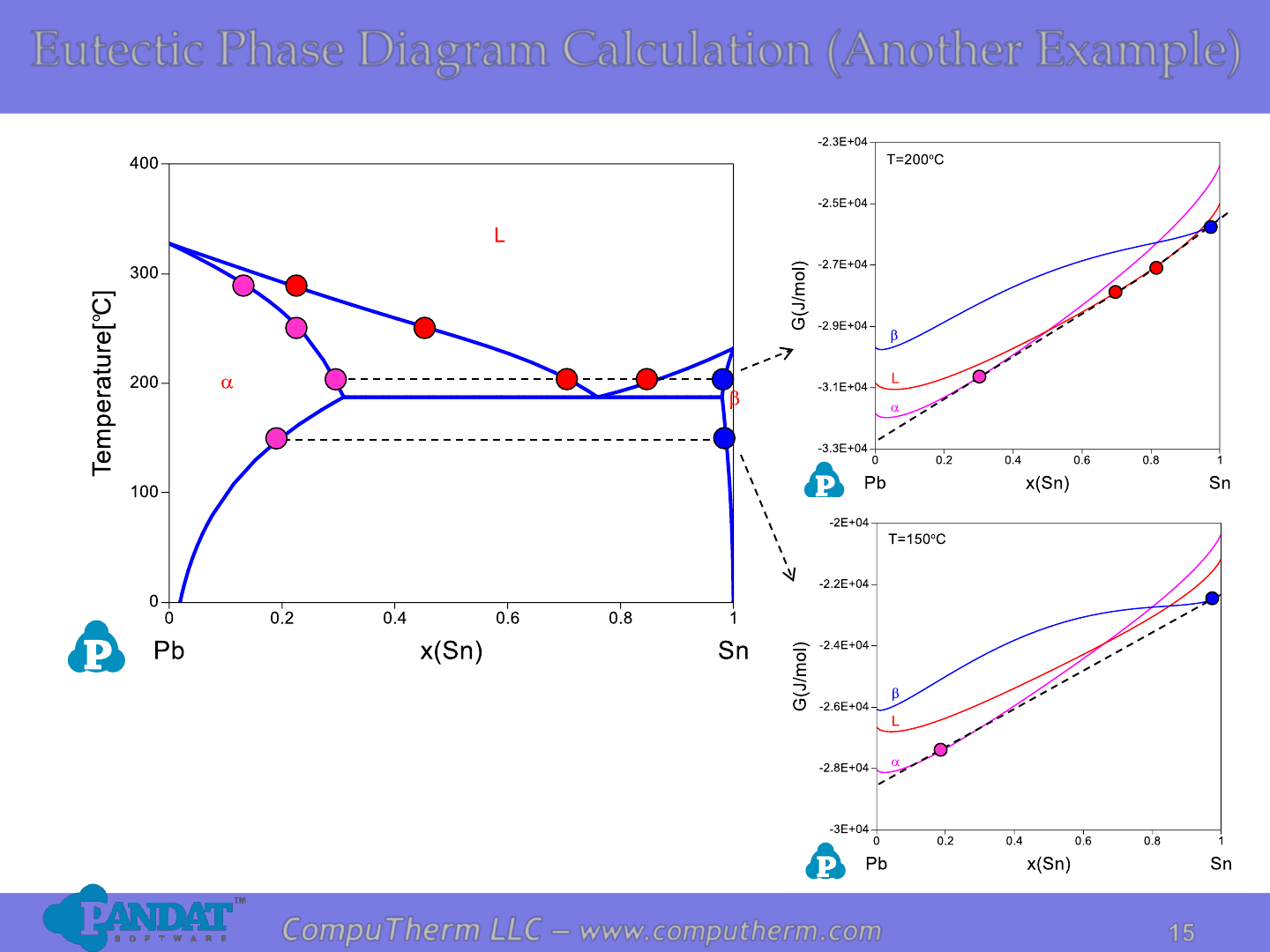

Eutectic Phase Diagram Calculation (Another Example)

Details Refer to:

1. Database: Database_Eutectic_Pb-Sn.tdb

2. Tutorial Video: Binary_Eutectic

16

16

CompuTherm LLC – www.computherm.com

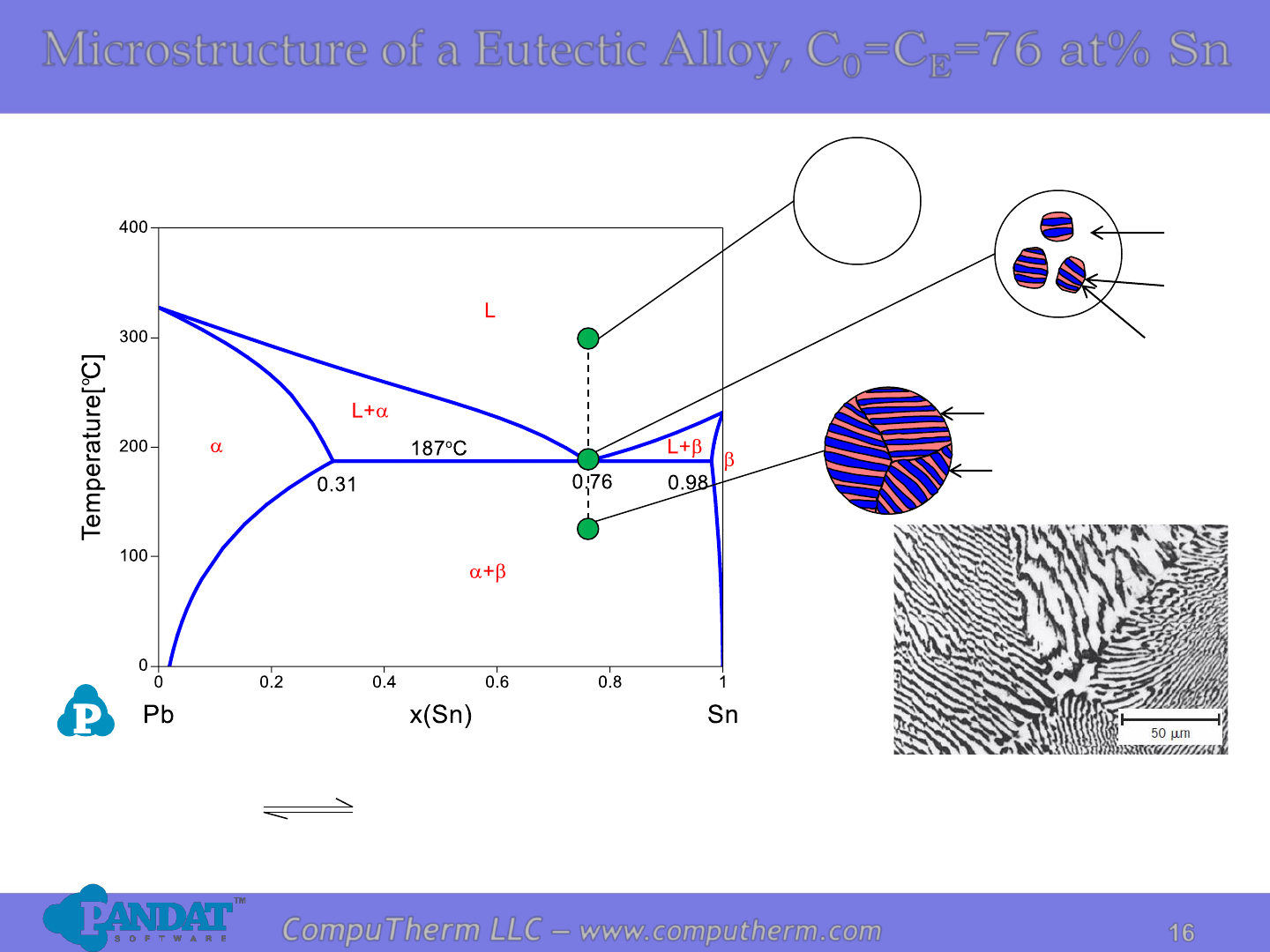

Sn) at% 89( Sn) at% (31 Sn) at% 76(

a

+L

cooling

heating

Microstructure of a Eutectic Alloy, C

0

=C

E

=76 at% Sn

L

(76%Sn)

L

(76%Sn)

a

(31%Sn)

(98%Sn)

a

(31%Sn)

(98%Sn)

The dark layers are Pb-rich

α phase, and the light

layers are Sn-rich β phase.

Photo copyright by Metals Handbook Vol. 9, 1985.

17

17

CompuTherm LLC – www.computherm.com

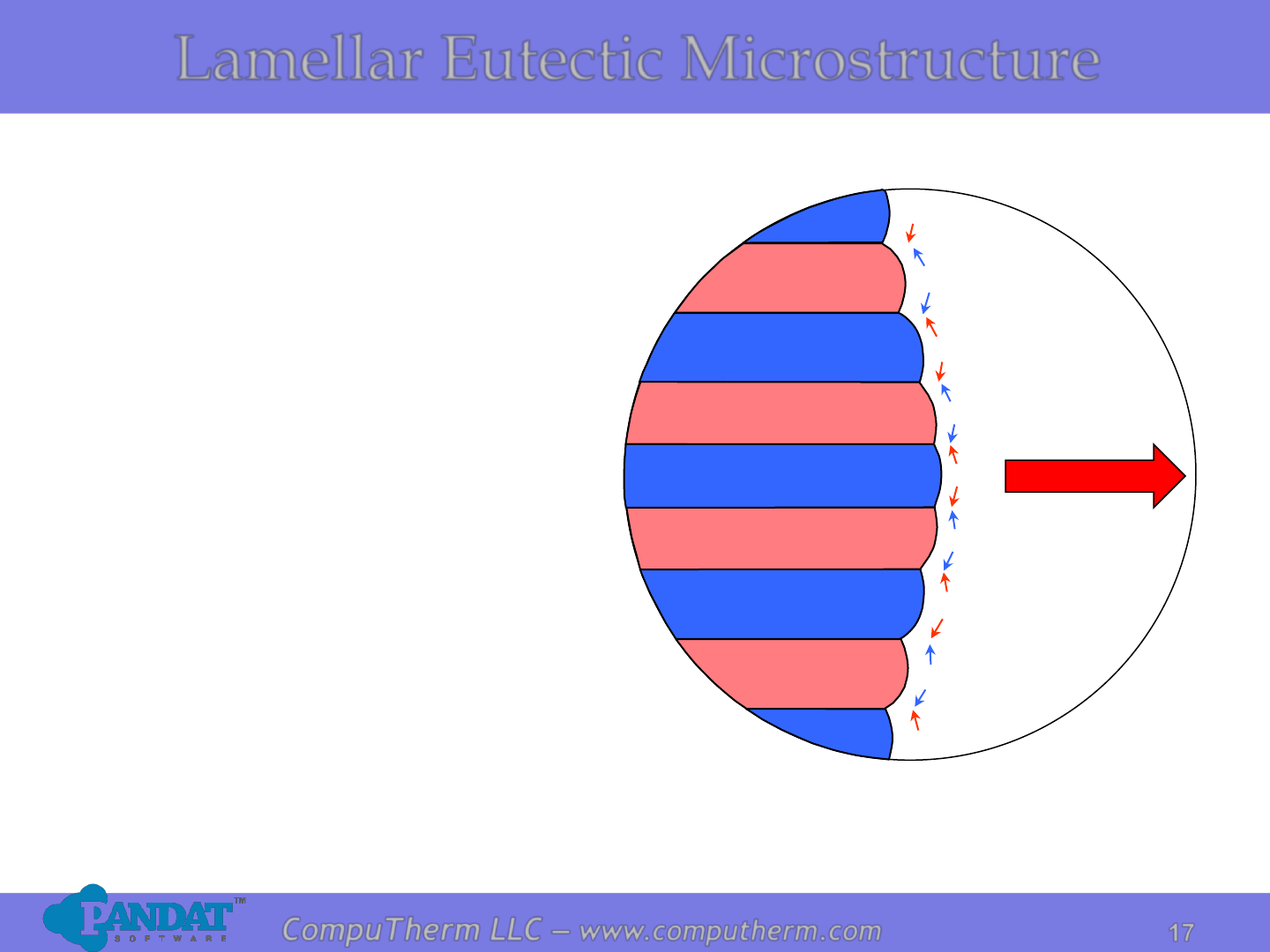

Lamellar Eutectic Microstructure

❑A two-phase lamellar

microstructure resulting

from the solidification of a

liquid having the eutectic

composition.

Eutectic

growth

direction

Liquid

a

a

a

a

Pb

Pb

Pb

Pb

Pb

Sn

Sn

Sn

Sn

❑Compositions of α and β

phases are very different.

Solidification involves

redistribution of Pb and Sn

atoms by atomic diffusion.

18

18

CompuTherm LLC – www.computherm.com

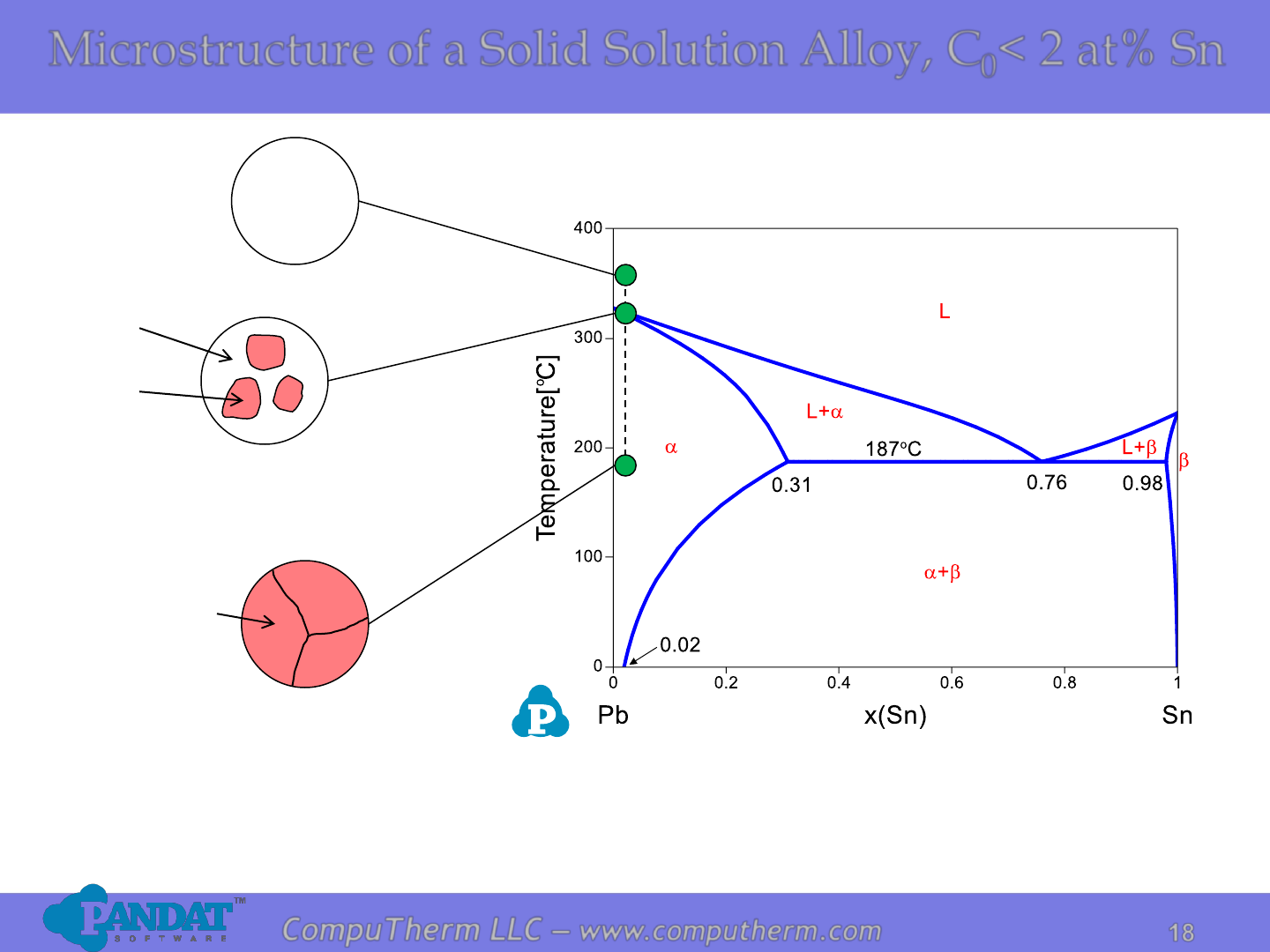

Microstructure of a Solid Solution Alloy, C

0

< 2 at% Sn

L

(C

0

)

L

a

a

(C

0

)

19

19

CompuTherm LLC – www.computherm.com

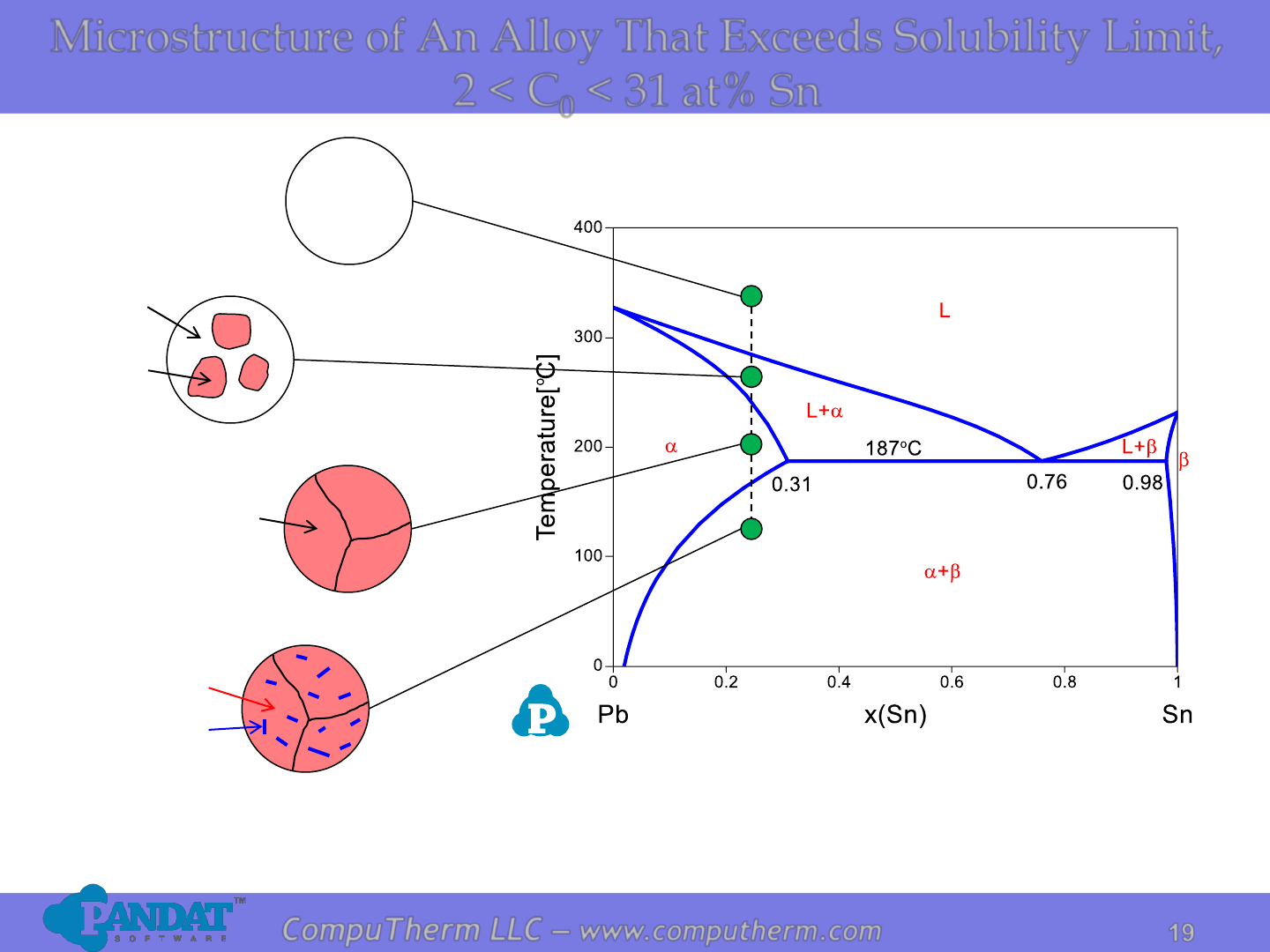

Microstructure of An Alloy That Exceeds Solubility Limit,

2 < C

0

< 31 at% Sn

L

(C

0

)

L

a

a

(C

0

)

a

20

20

CompuTherm LLC – www.computherm.com

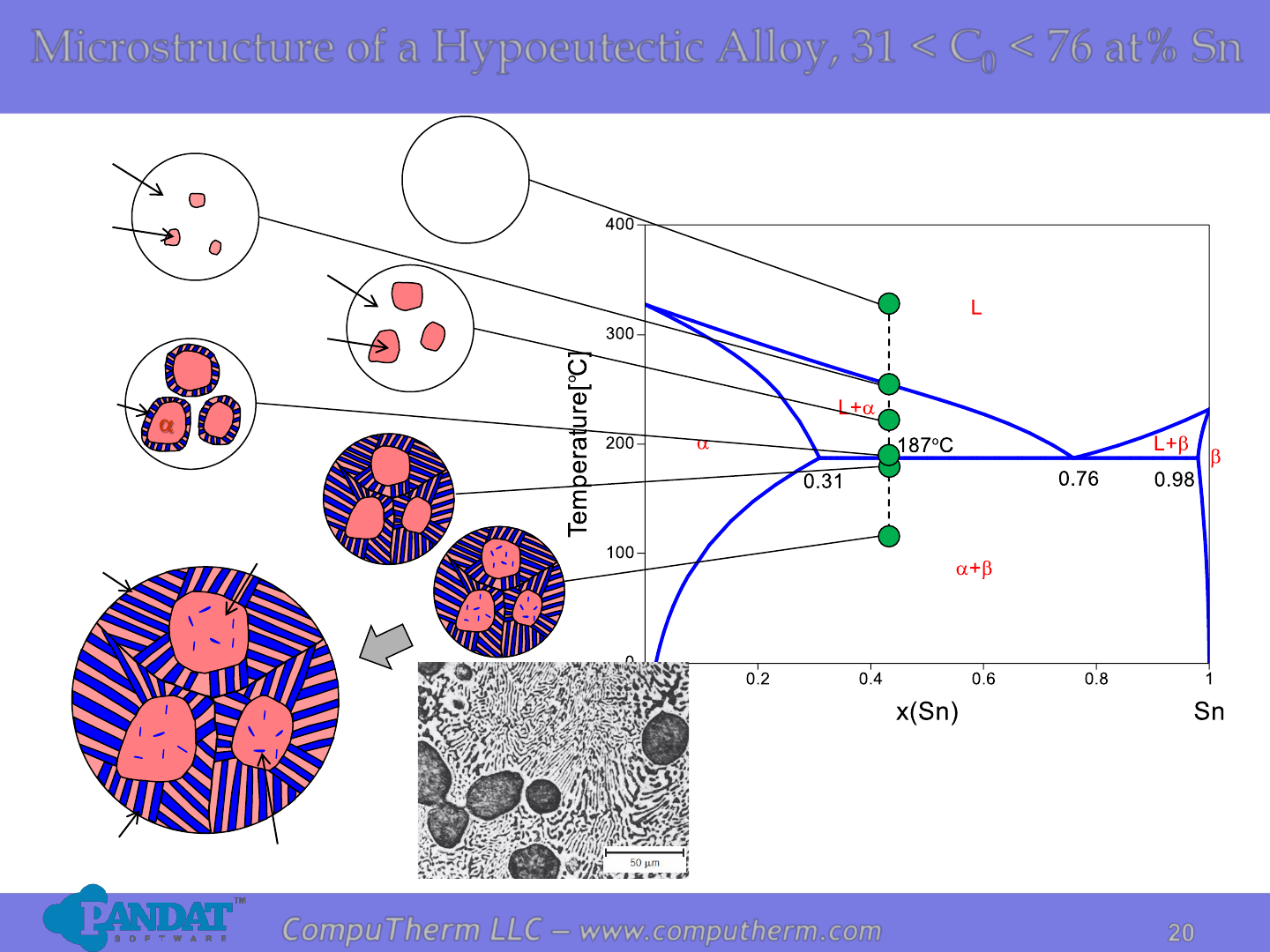

Microstructure of a Hypoeutectic Alloy, 31 < C

0

< 76 at% Sn

L

L

a

L

a

L

Primary a

Eutectic a

Eutectic

Precipitate

The dark layers are Pb-rich α phase,

and the light layers are Sn-rich β phase.

Photo copyright by Metals

Handbook Vol. 9, 1985.

21

21

CompuTherm LLC – www.computherm.com

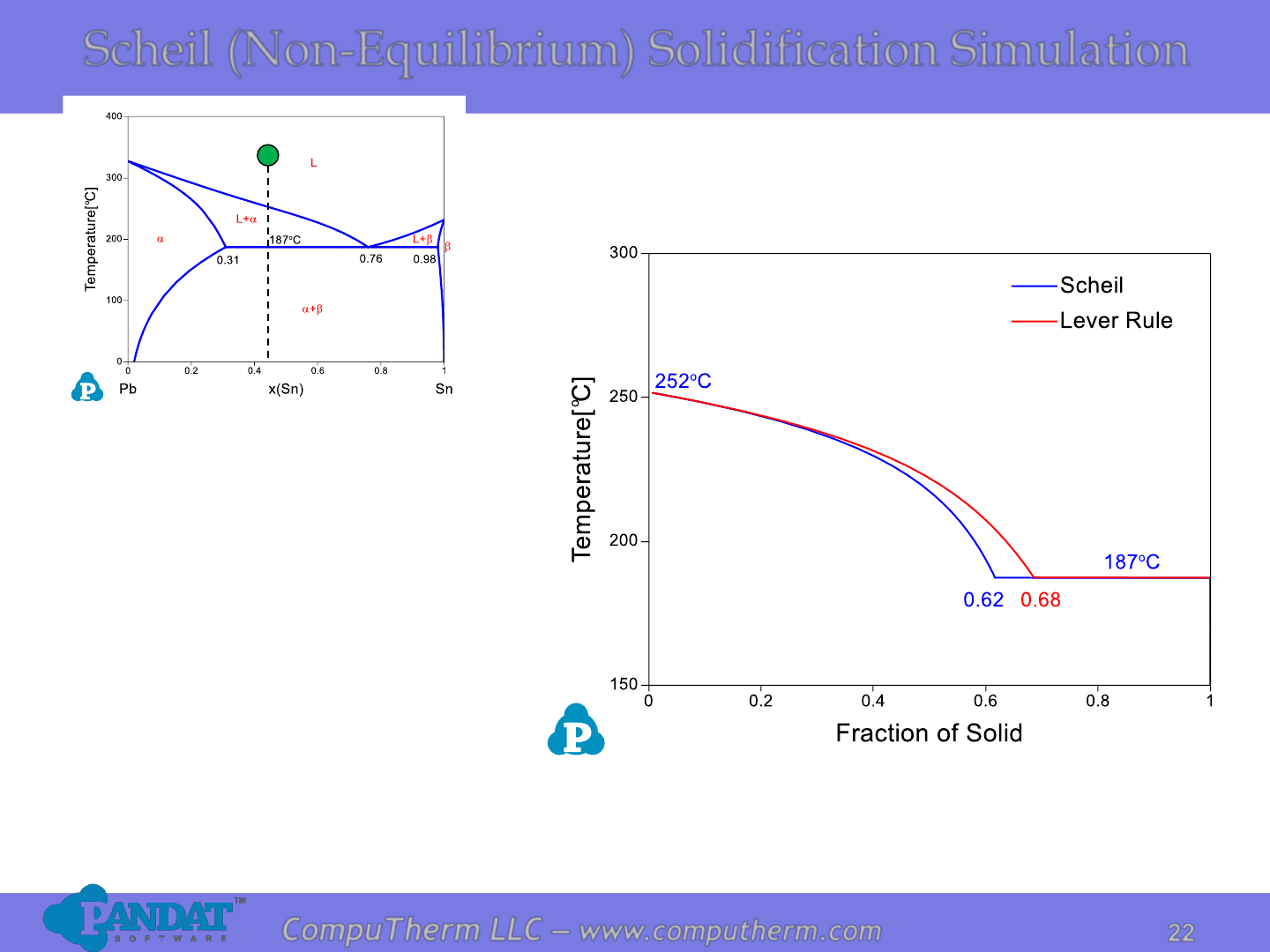

Scheil (Non-Equilibrium) Solidification Simulation

Assumptions for Scheil Simulation:

•Planar solid/liquid interface and negligible undercooling

•Local equilibrium at the solid/liquid interface

•Complete diffusion in liquid phase

•No diffusion in solid phase

•Density of liquid equals density of solid

In Reality:

•Planar/sphere/… S/L interface and considerable undercooling

•Large diffusion in liquid phase

•Limited diffusion in solid phase

•Density of liquid does not equal to density of solid

Scheil simulation is good for fast cooling of systems with small amount.

22

22

CompuTherm LLC – www.computherm.com

Scheil (Non-Equilibrium) Solidification Simulation

When the alloy hits the eutectic

temperature at 187

o

C, the liquid

transforms to a + mixture and

remains at the same temperature

until all the liquid is gone.

The final a phase fraction contains

two parts: primary a phase (~62%)

and eutectic a phase in the

eutectic mixture (~38%).

f(a) = 62%+38%*33% = 74%

f() = 38%*67% = 26%

For the Alloy Pb-45at%Sn, the

liquid starts to solidify at 252

o

C

and the a phase is the product.

23

23

CompuTherm LLC – www.computherm.com

Types of Binary Phase Diagrams

• Isomorphous Systems

• Eutectic Systems

• Eutectoid Systems

• Peritectic Systems

• Peritectoid Systems

• Monotectic Systems

• Syntectic Systems

24

24

CompuTherm LLC – www.computherm.com

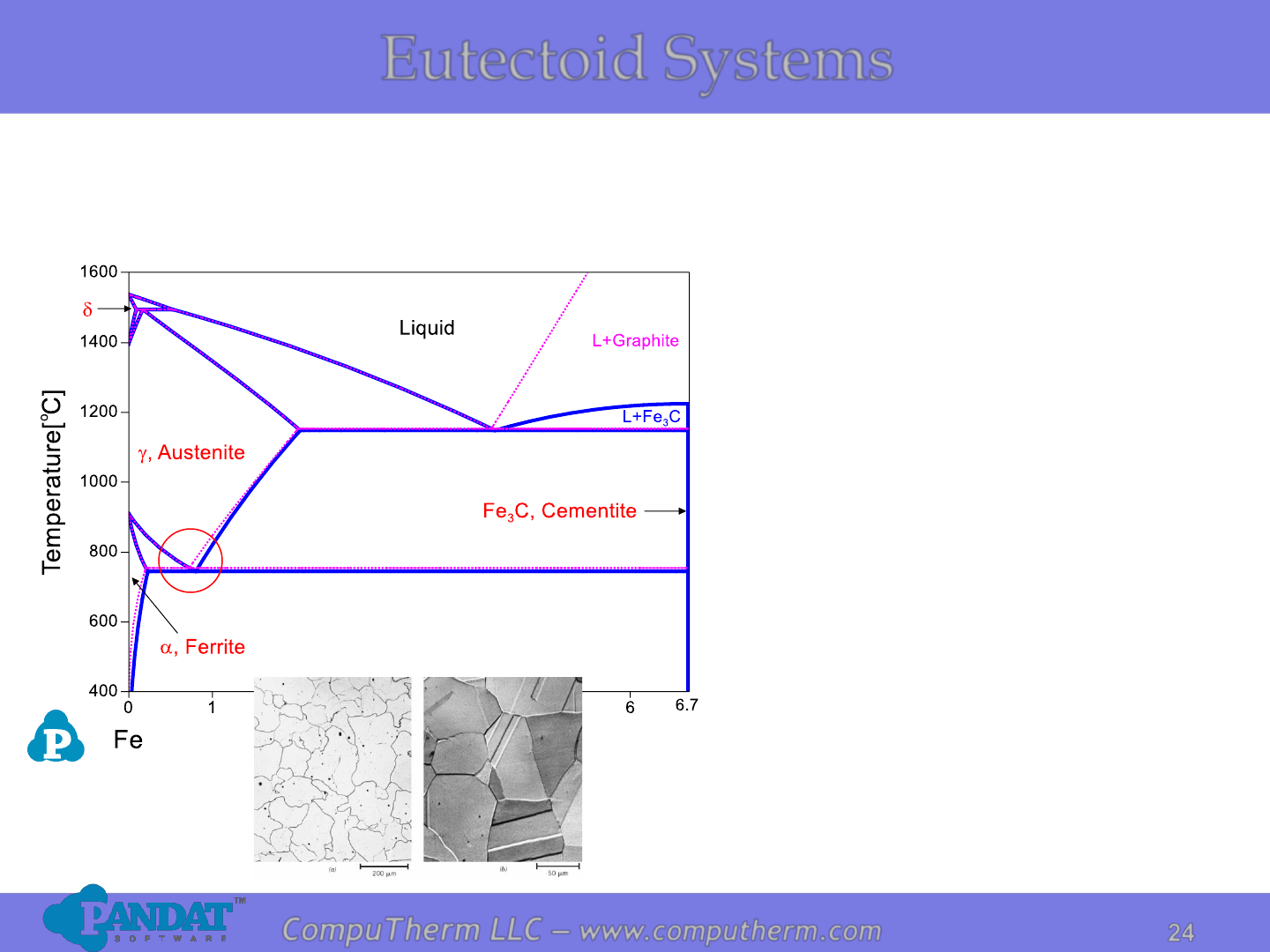

Eutectoid Systems

Information from this diagram:

• Fe-C stable phase boundaries

are represented by pink dot

lines, and Fe-Fe

3

C metastable

phase boundaries are

represented by blue solid lines.

• Fe

3

C phase is a line compound

(6.7 wt% of Carbon) without

any solubility.

• Carbon is an interstitial

impurity in iron and forms a

solid solution with the a, g, d

phases.

• Eutectoid reaction is a solid

state reaction with no liquid

involved: g ↔ a + Fe

3

C.

Photo copyright by United States Steel Corporation.

a, Ferrite

g, Austenite

25

25

CompuTherm LLC – www.computherm.com

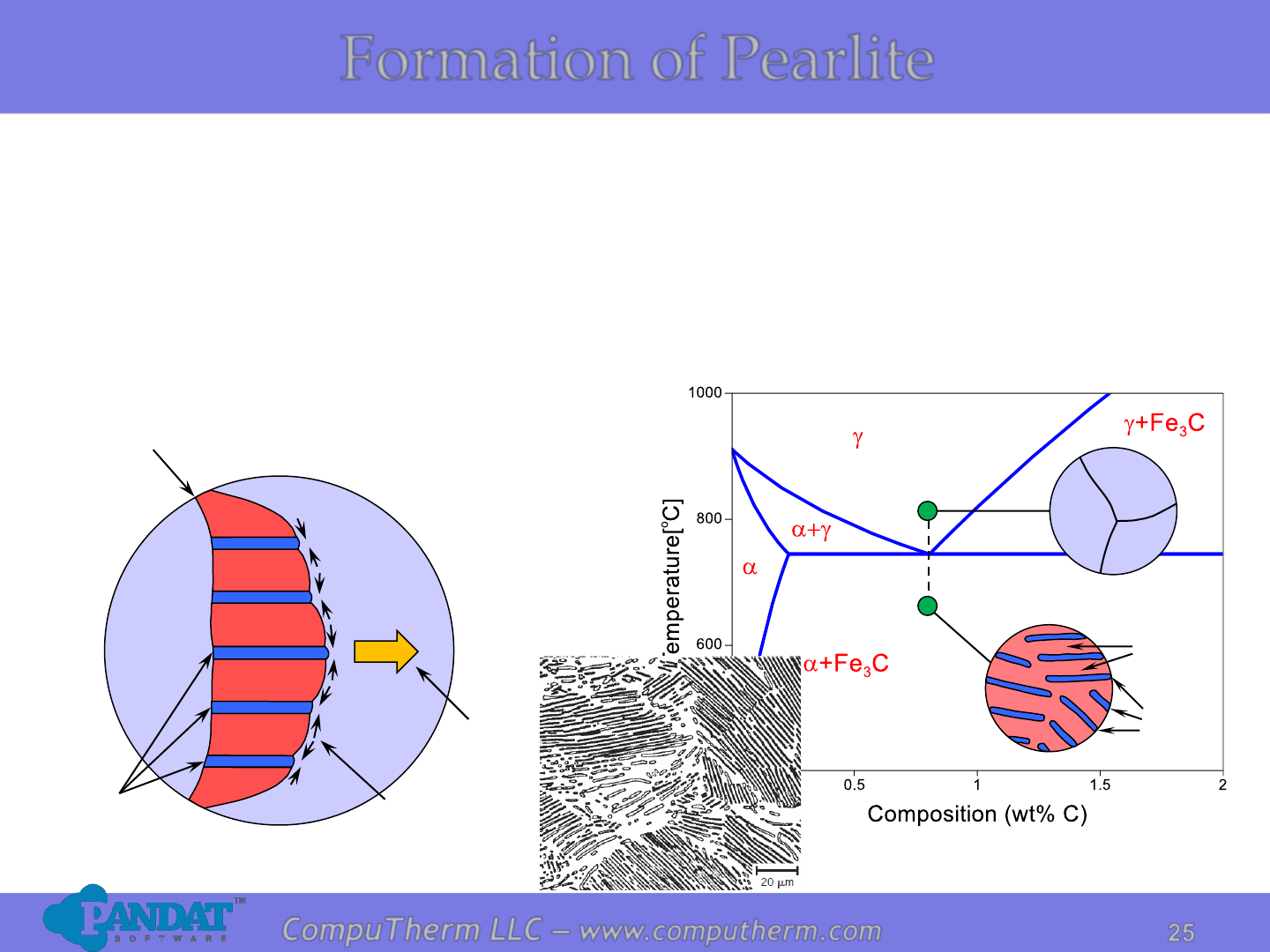

Formation of Pearlite

Due to the eutectoid reaction: g ↔ a + Fe

3

C, pearlite structure is formed.

Pearlite: alternating layers of a and Fe

3

C phases, not a single phase.

Growth

direction of

pearlite

Austenite

(g)

Austenite

(g)

Cementite

(Fe

3

C)

Ferrite(a)

Ferrite(a)

Ferrite(a)

Ferrite(a)

a

a

Carbon

diffusion

Austenite

grain

boundary

g

g

g

a

Fe

3

C

• Nucleating at g grain boundaries.

• Growth by diffusion of carbon to achieve the compositions of a and Fe

3

C

(with structure changes).

• According to lever rule, the amount of a is much larger than that of Fe

3

C,

resulting in a much thicker a lamellae.

Photo copyright by Metals Handbook Vol. 9, 1985.

26

26

CompuTherm LLC – www.computherm.com

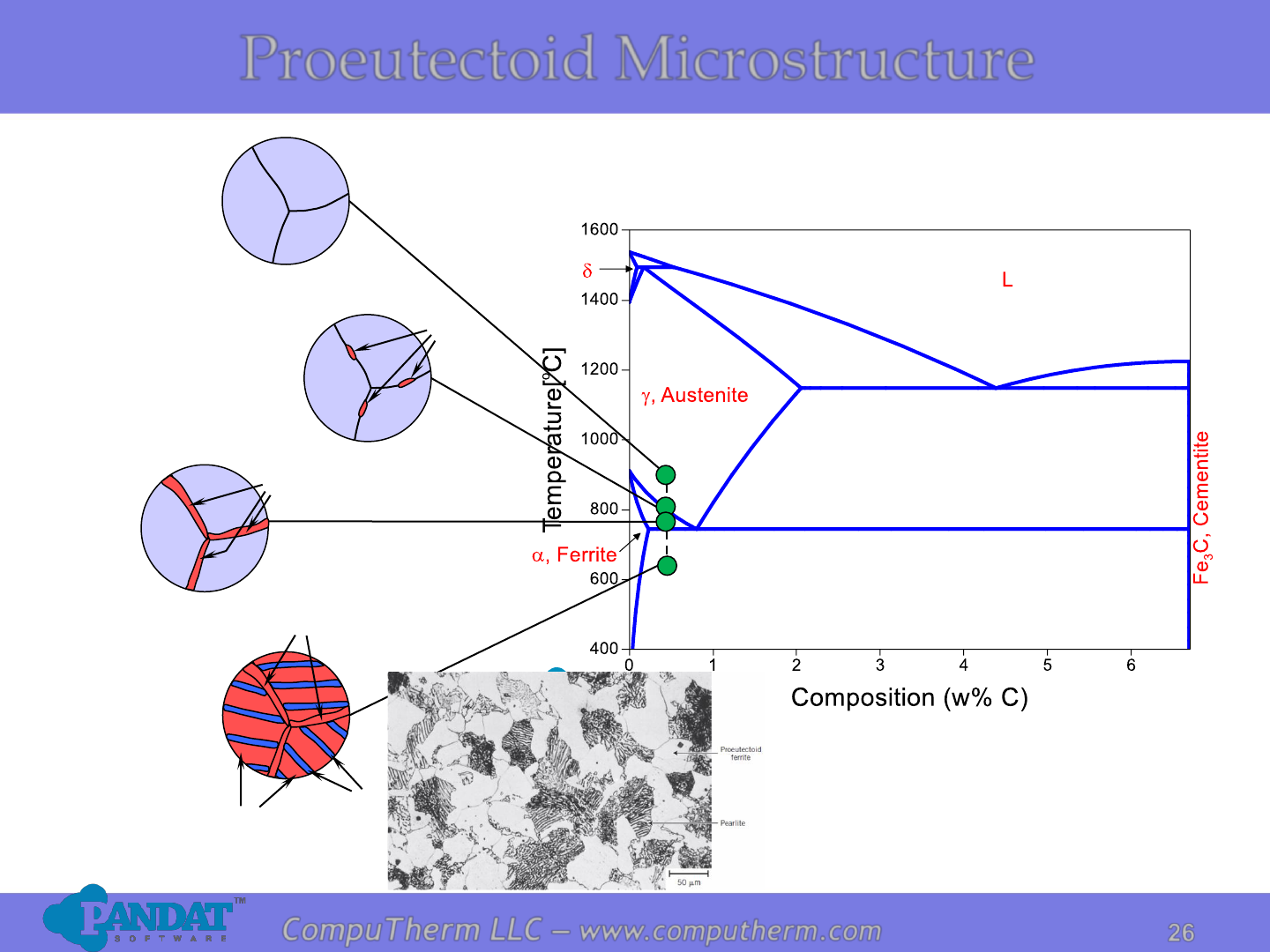

g

g

g

g

g

g

a

g

g

g

a

Proeutectoid a

Eutectoid a

Fe

3

C

Proeutectoid Microstructure

Photo copyright by Republic Steel Corporation.

27

27

CompuTherm LLC – www.computherm.com

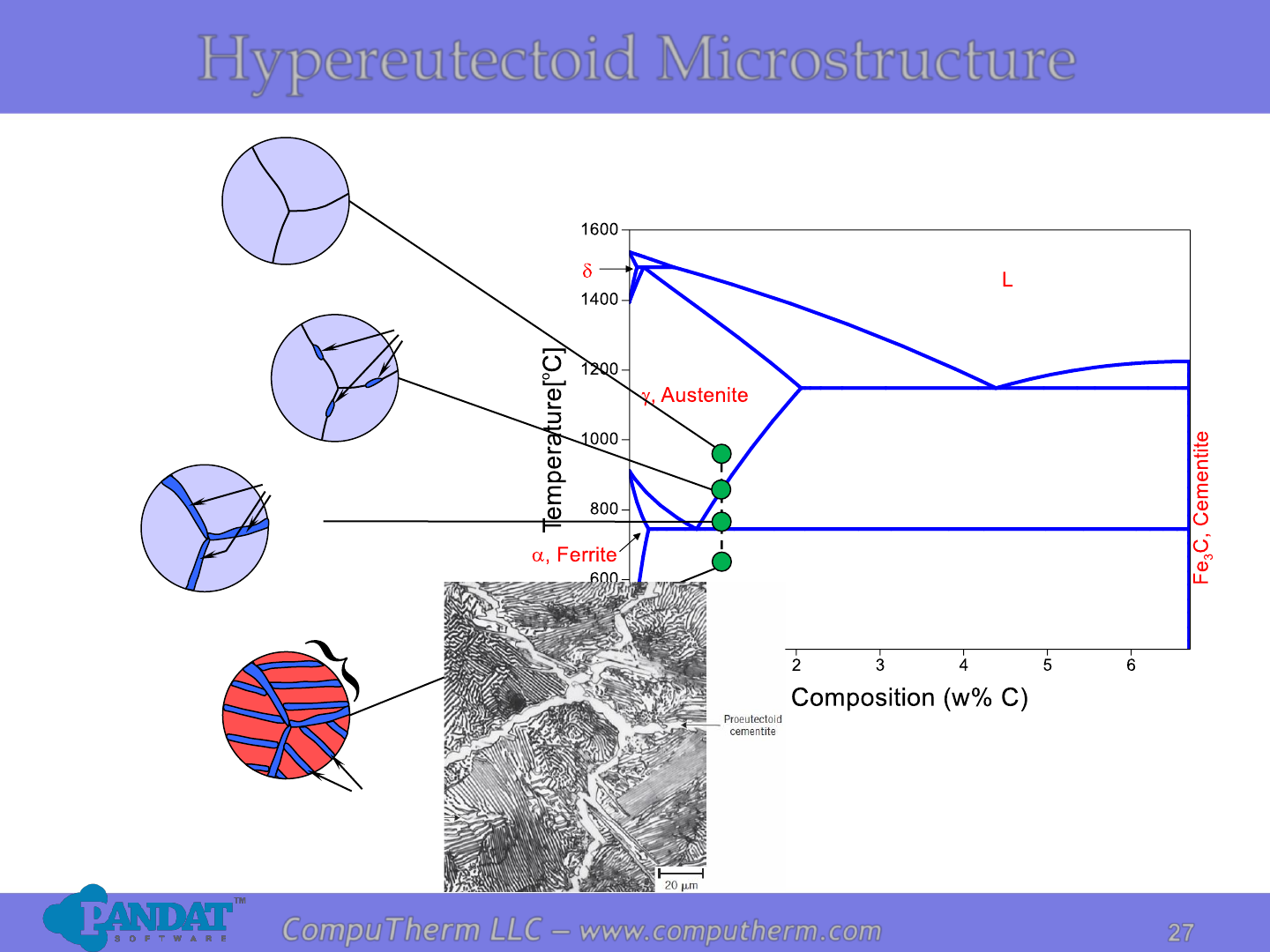

g

g

g

g

g

g

Fe

3

C

g

g

g

Fe

3

C

Hypereutectoid Microstructure

Fe

3

C

Pearlite

Photo copyright by United States Steel Corporation.

28

28

CompuTherm LLC – www.computherm.com

Types of Binary Phase Diagrams

• Isomorphous Systems

• Eutectic Systems

• Eutectoid Systems

• Peritectic Systems

• Peritectoid Systems

• Monotectic Systems

• Syntectic Systems

29

29

CompuTherm LLC – www.computherm.com

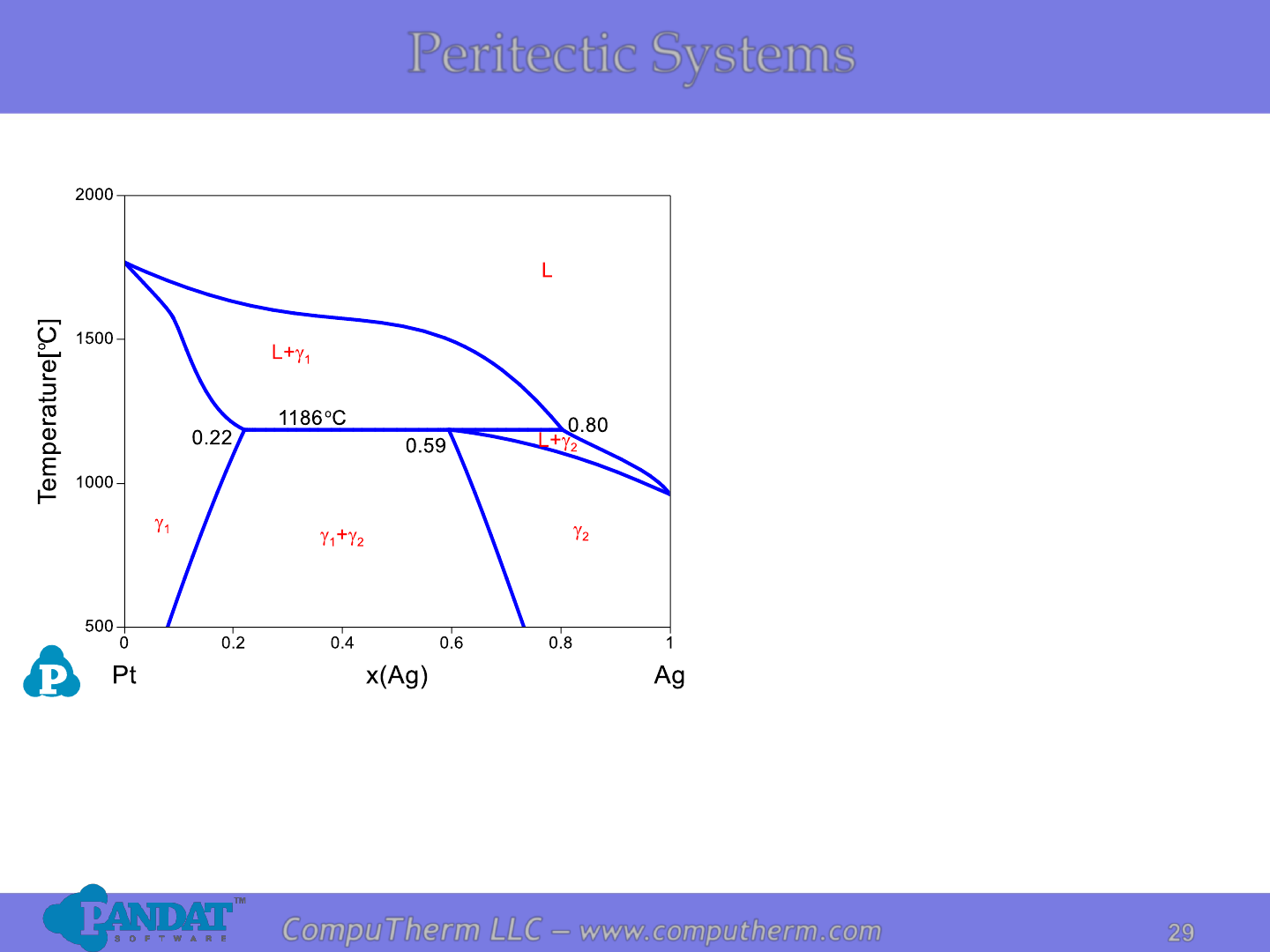

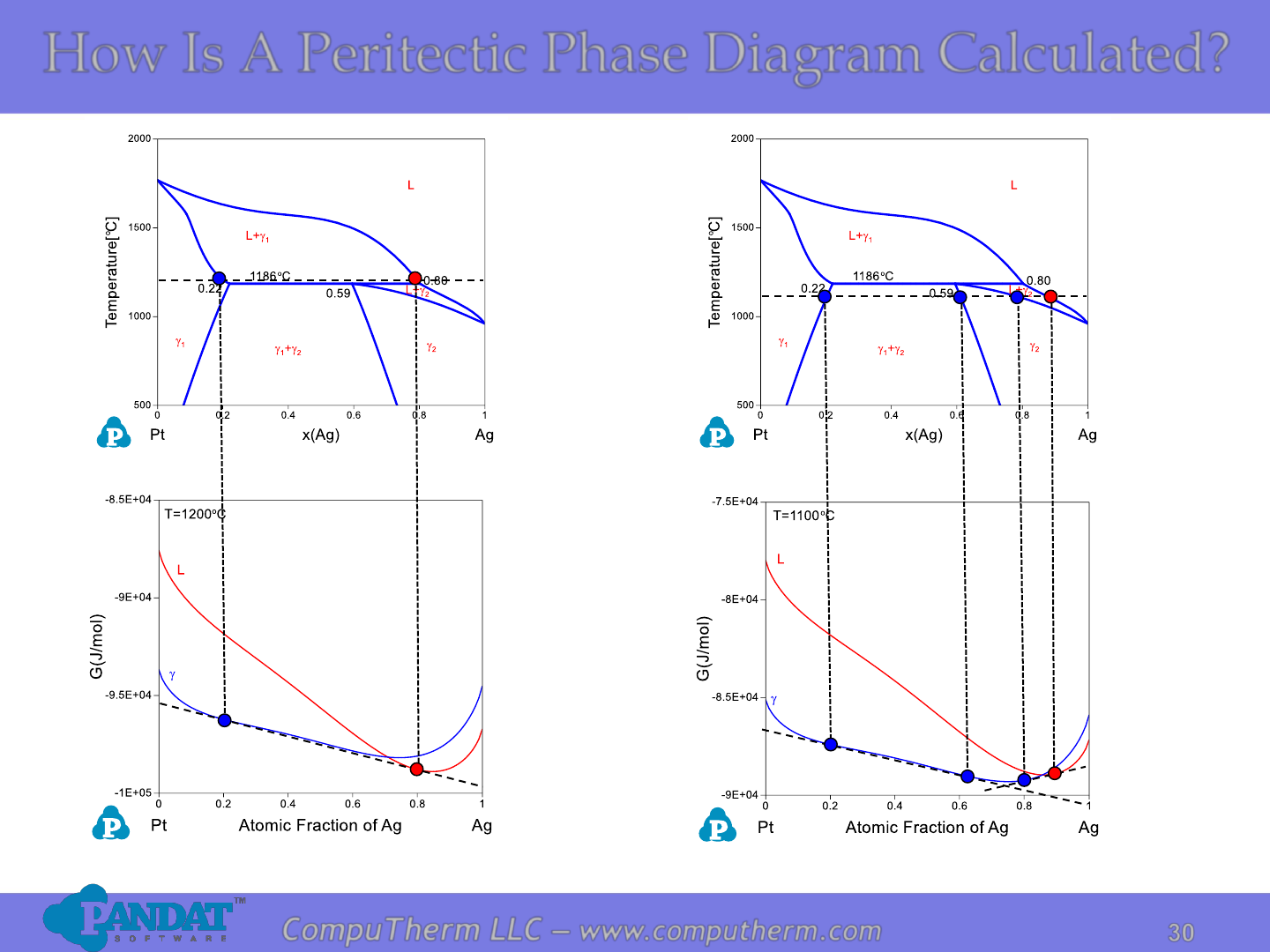

Peritectic Systems

Information from this diagram:

• Peritectic reaction occurs at

1186

o

C and 80 at% Ag:

L + g

1

↔ g

2

.

• Alloy (22%<x

Ag

<59%) starts to

melt at peritectic reaction

temperature 1186

o

C and

becomes complete liquid at

liquidus.

• Alloy (x

Ag

<22% or x

Ag

>59%)

starts to melt at solidus, and

becomes complete liquid at

liquidus.

Details Refer to:

1. Database: Database_Peritectic_Ag-Pt.tdb

2. Tutorial Video: Binary_Peritectic

30

30

CompuTherm LLC – www.computherm.com

How Is A Peritectic Phase Diagram Calculated?

31

31

CompuTherm LLC – www.computherm.com

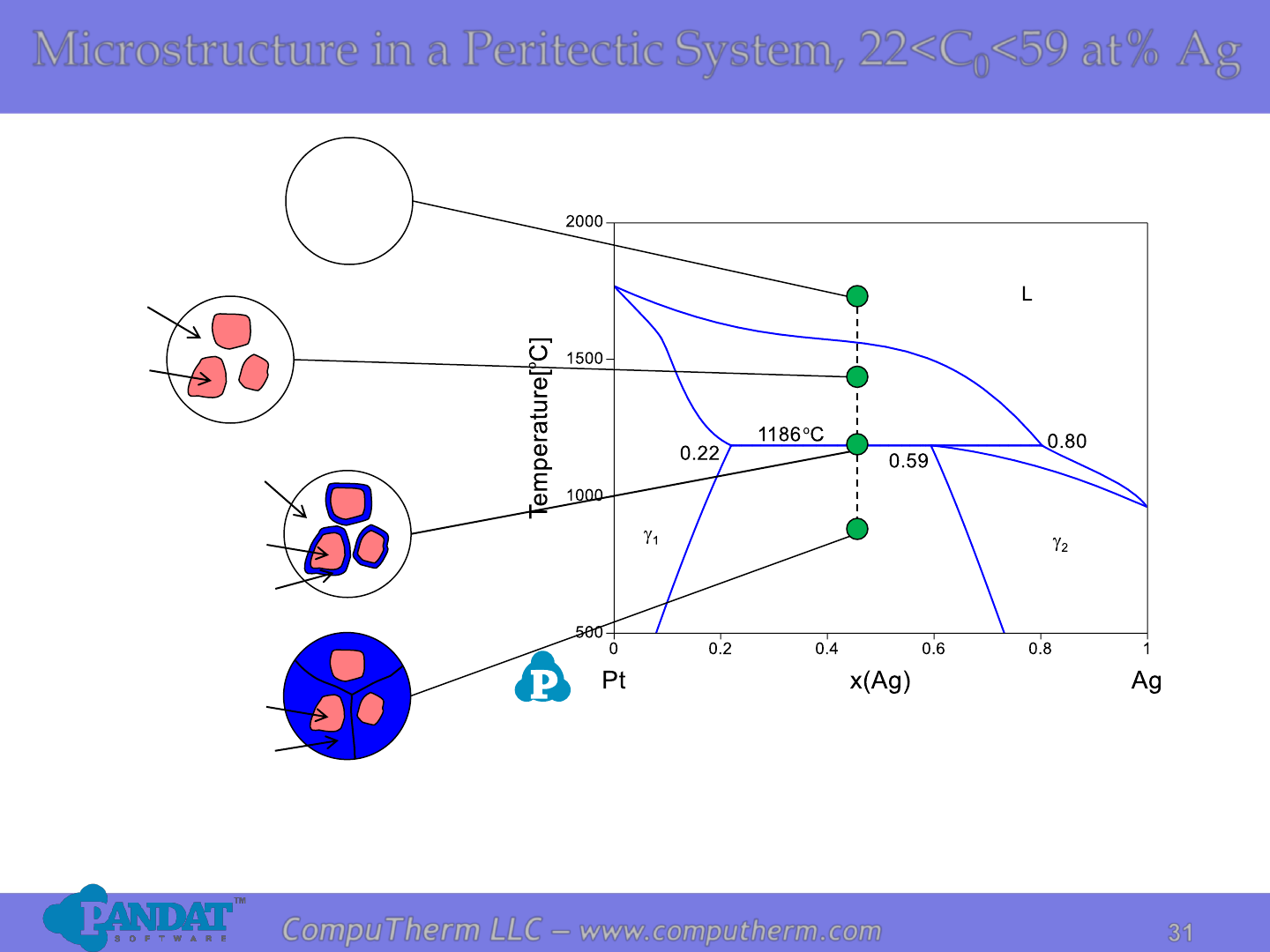

Microstructure in a Peritectic System, 22<C

0

<59 at% Ag

L

L

g

1

g

1

g

2

L

g

1

g

2

32

32

CompuTherm LLC – www.computherm.com

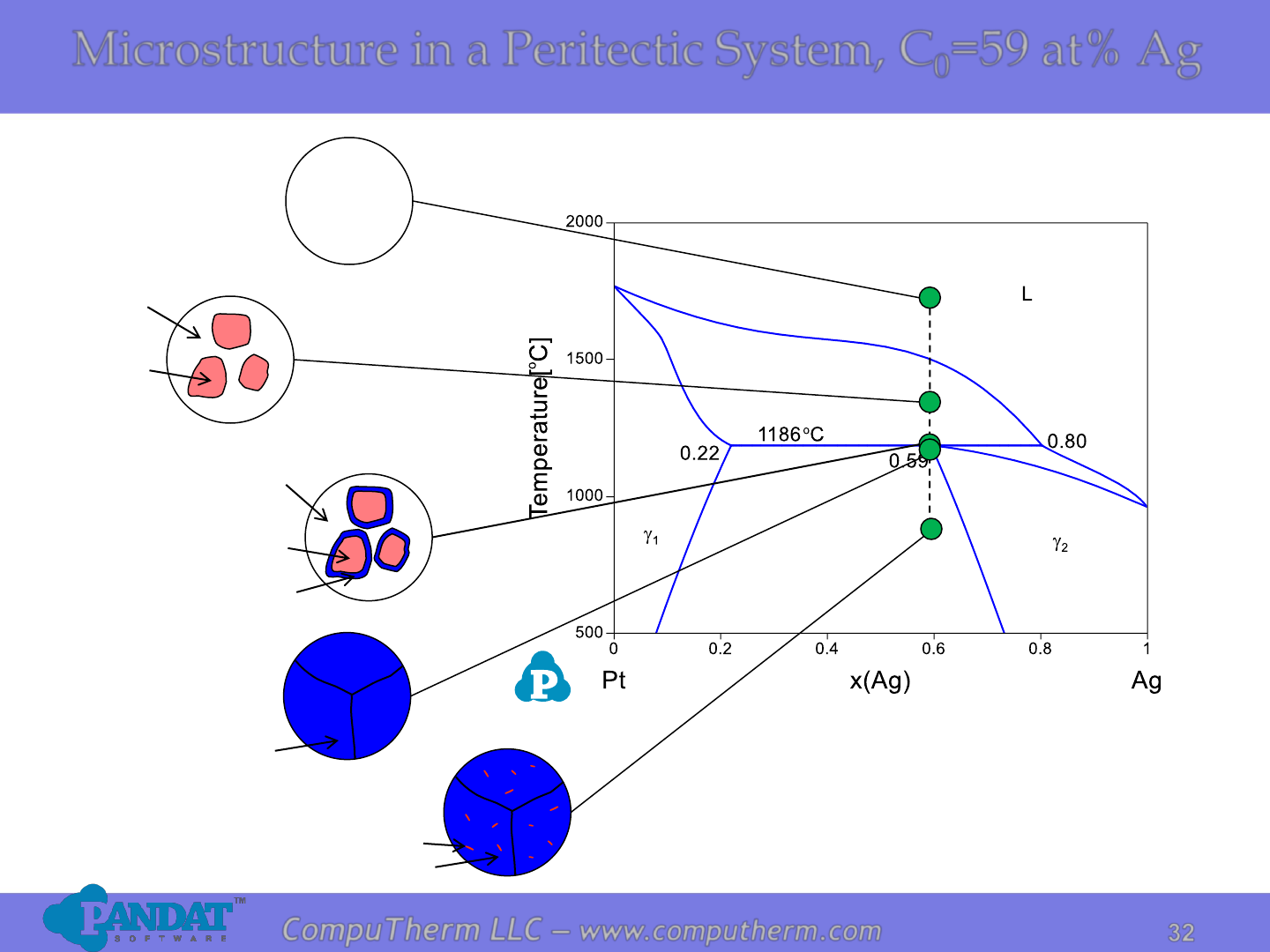

Microstructure in a Peritectic System, C

0

=59 at% Ag

L

L

g

1

L

g

1

g

2

g

2

g

2

Precipitate g

1

33

33

CompuTherm LLC – www.computherm.com

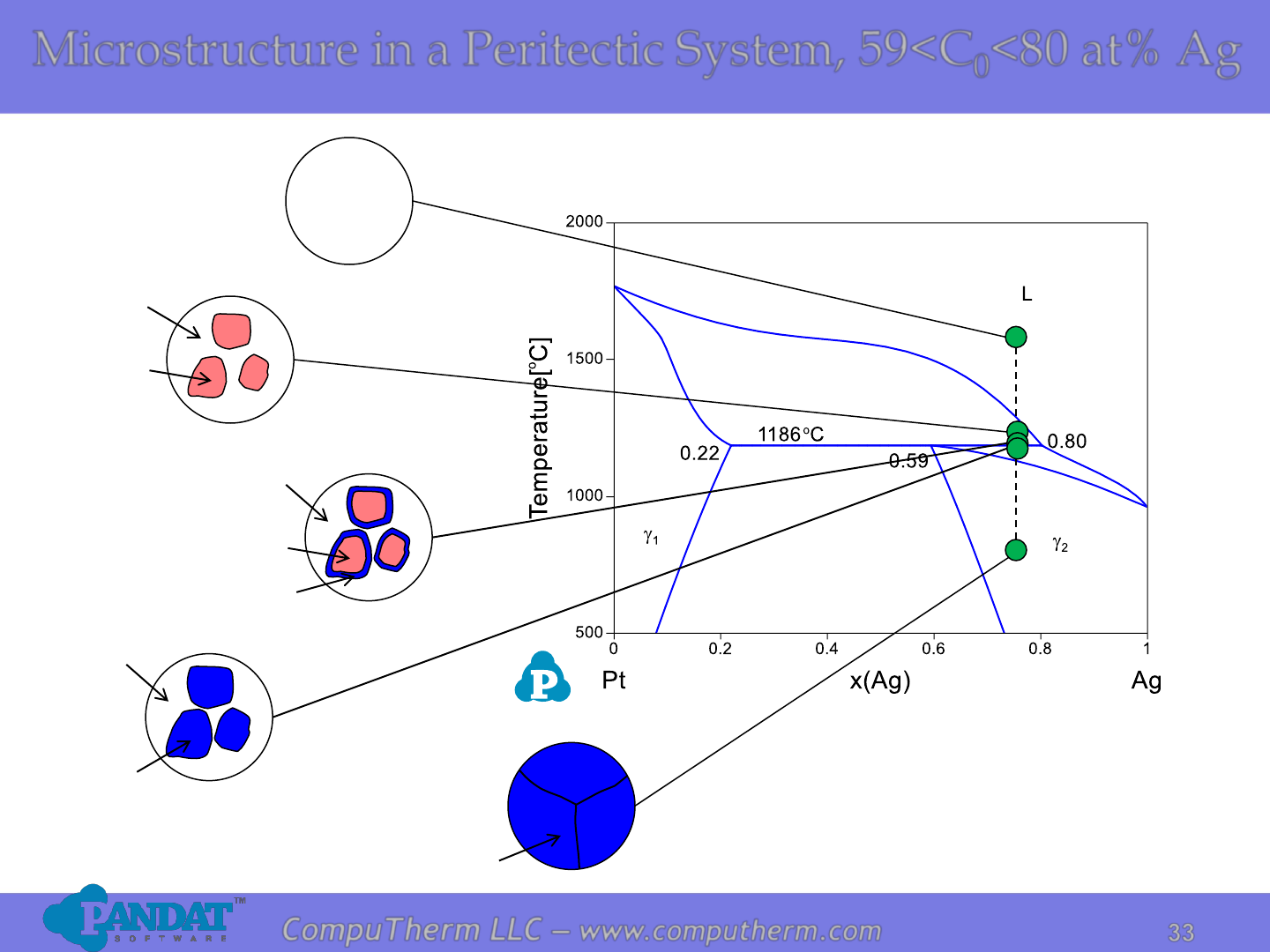

Microstructure in a Peritectic System, 59<C

0

<80 at% Ag

L

L

g

1

L

g

1

g

2

g

2

L

g

2

34

34

CompuTherm LLC – www.computherm.com

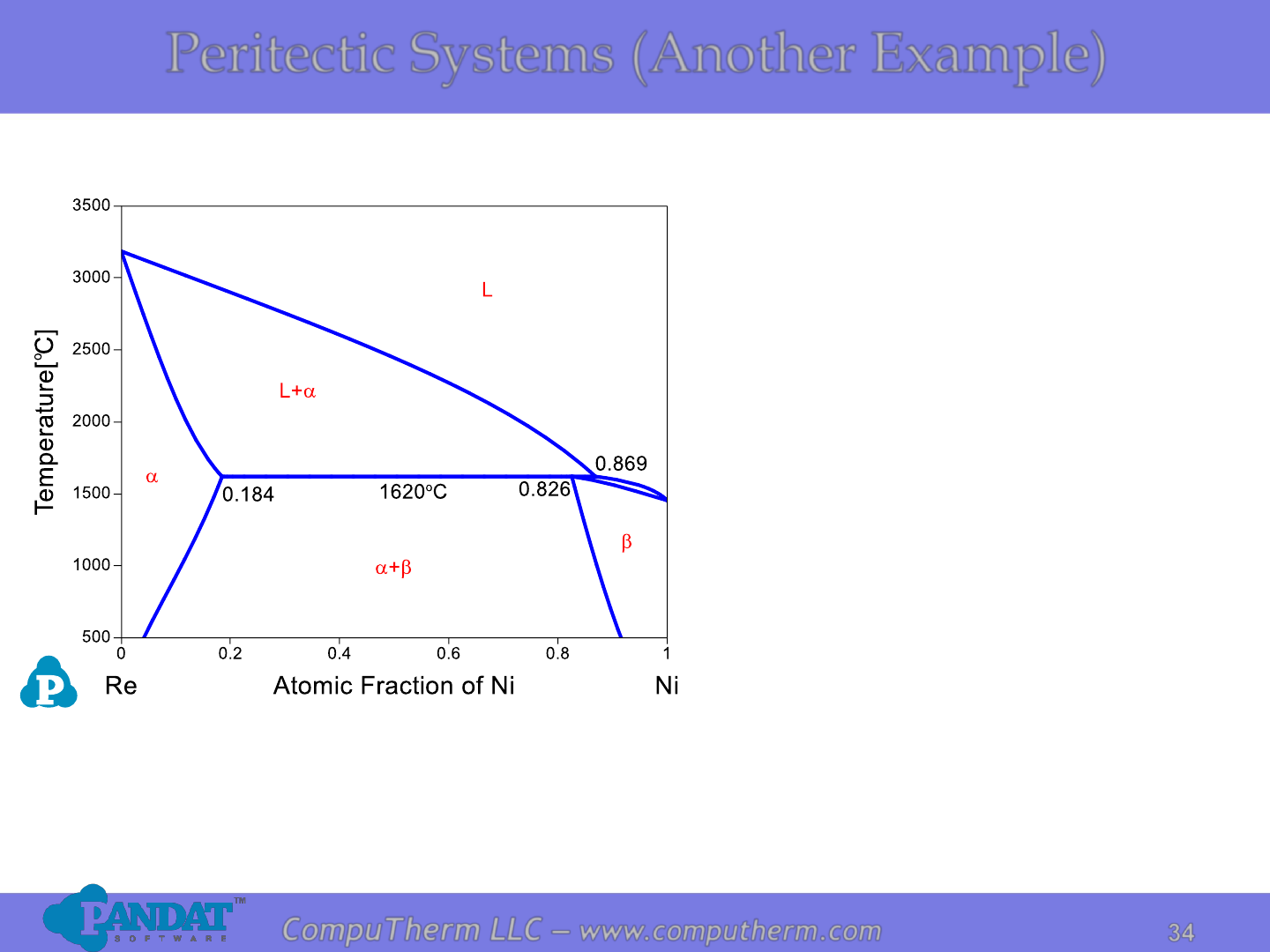

Peritectic Systems (Another Example)

Information from this diagram:

• Peritectic reaction occurs at

1620

o

C and 86.9 at% Ni:

L + a ↔ .

• Alloy (18.4%<x

Ni

<82.6%) starts

to melt at peritectic reaction

temperature 1620

o

C and

becomes complete liquid at

liquidus.

• Alloy (x

Ni

<18.4% or x

Ni

>86.9%)

starts to melt at solidus, and

becomes complete liquid at

liquidus.

Details Refer to:

1. Database: Database_Peritectic_Ni-Re.tdb

2. Tutorial Video: Binary_Peritectic

35

35

CompuTherm LLC – www.computherm.com

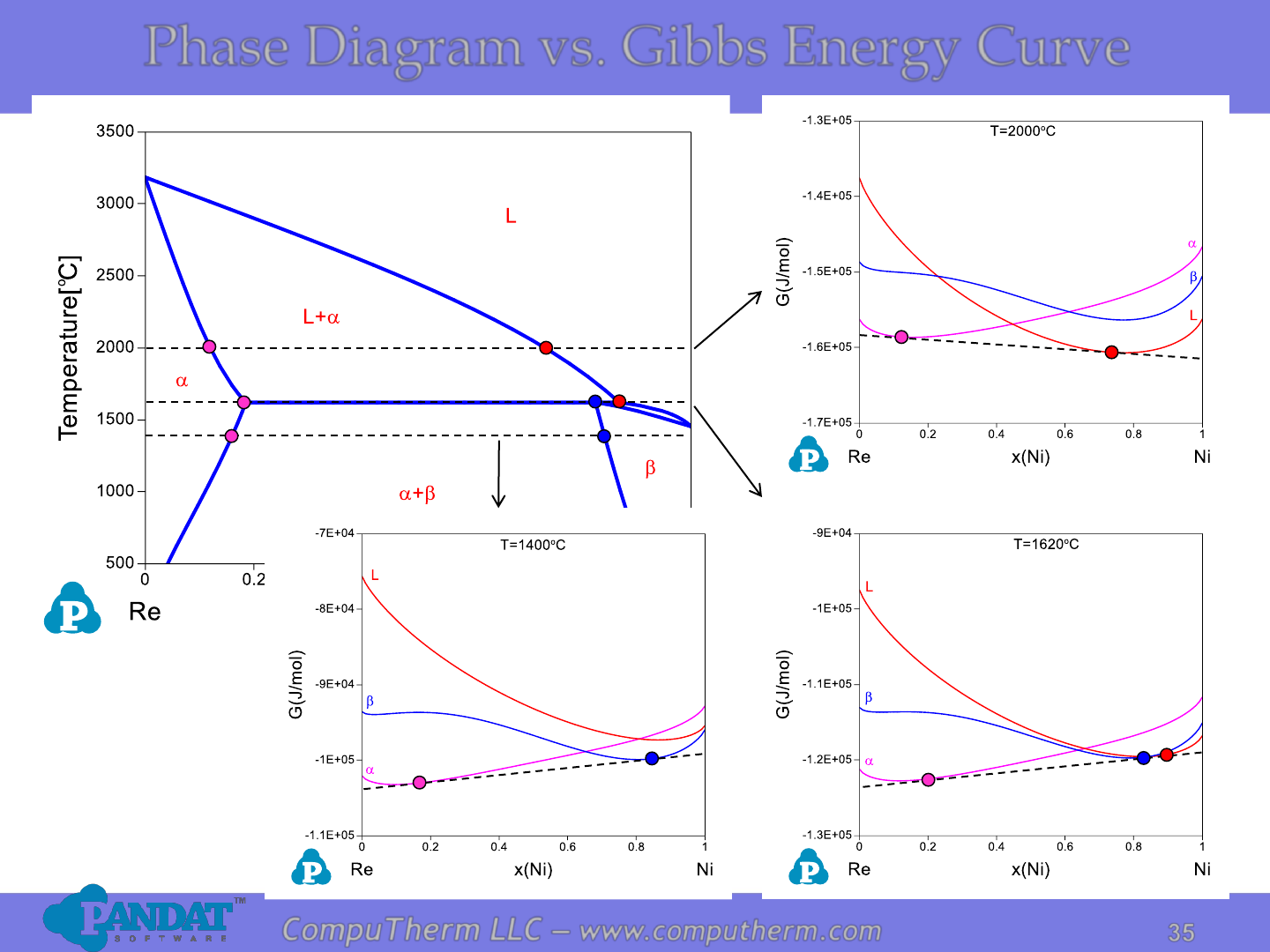

Phase Diagram vs. Gibbs Energy Curve

36

36

CompuTherm LLC – www.computherm.com

Types of Binary Phase Diagrams

• Isomorphous Systems

• Eutectic Systems

• Eutectoid Systems

• Peritectic Systems

• Peritectoid Systems

• Monotectic Systems

• Syntectic Systems

37

37

CompuTherm LLC – www.computherm.com

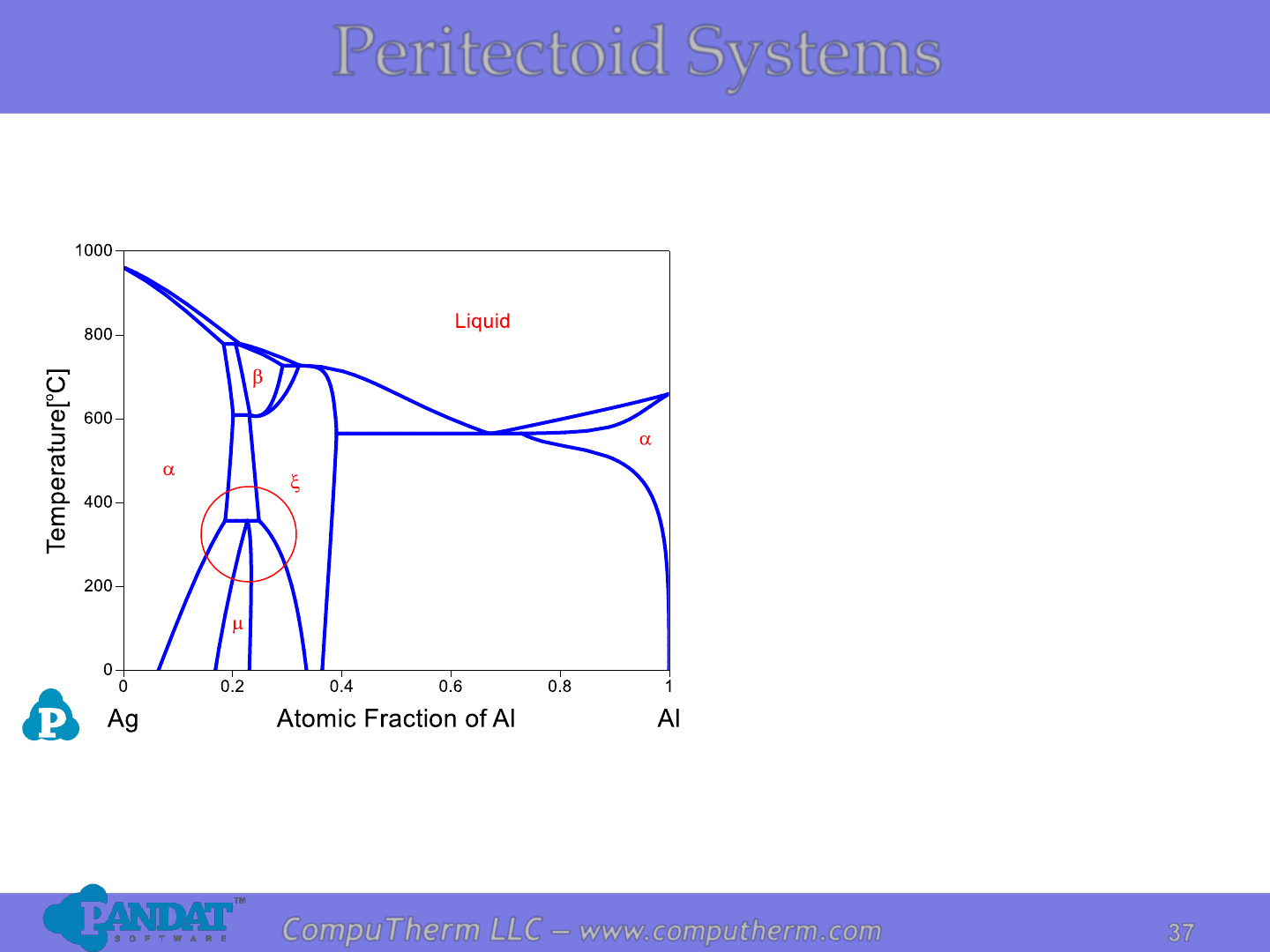

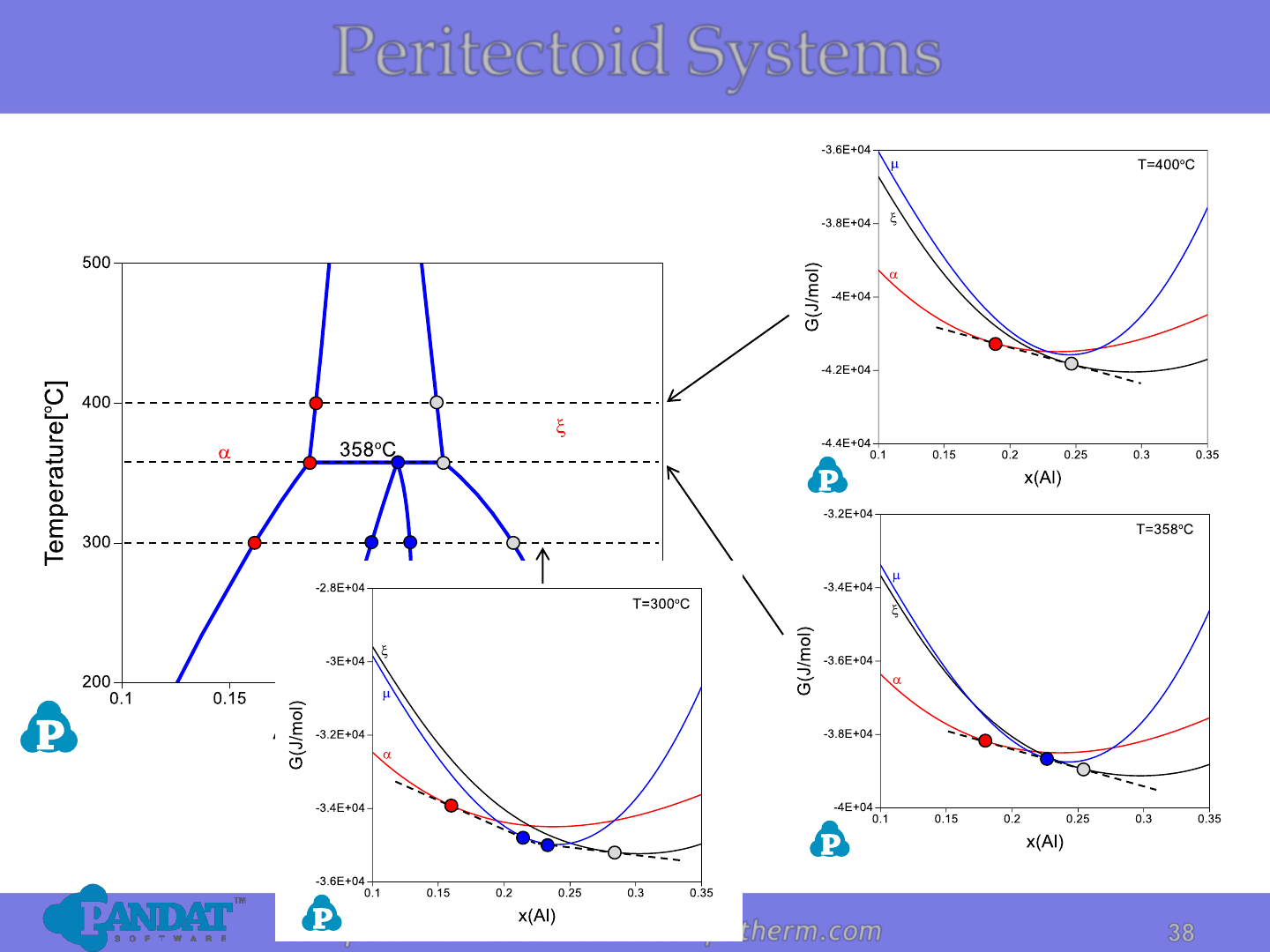

Information from this diagram:

• Peritectoid reaction is a solid

state reaction without any

liquid involved.

• Peritectoid reaction occurs at

358

o

C and 18.6 - 24.8 at% Al:

a + x ↔ m.

Peritectoid Systems

Details Refer to:

1. Database: Database_Peritectoid_Ag-Al.tdb

2. Tutorial Video: Binary_Peritectoid

38

38

CompuTherm LLC – www.computherm.com

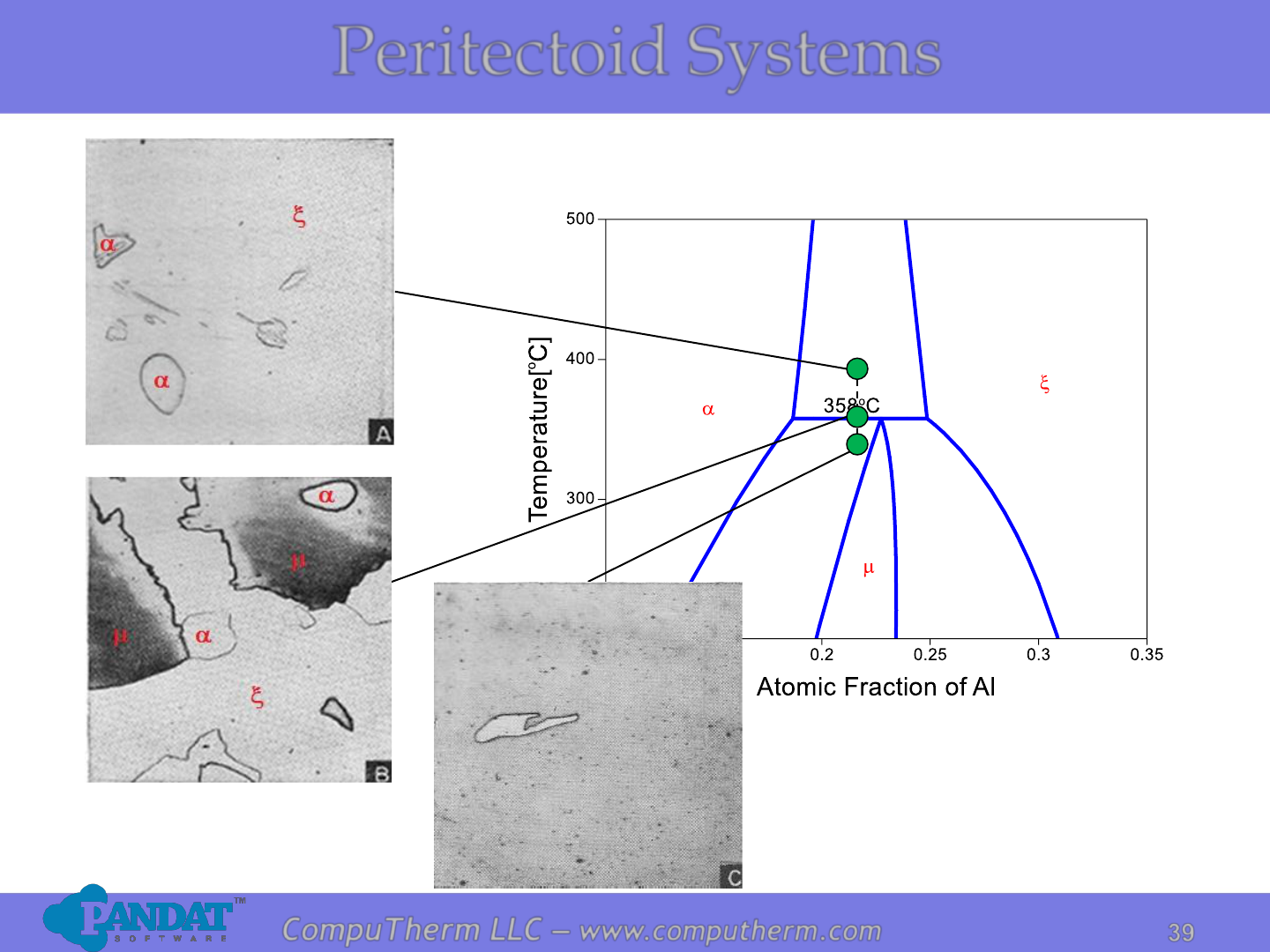

Peritectoid Systems

39

39

CompuTherm LLC – www.computherm.com

Peritectoid Systems

Photos from Phase Diagrams in Metallurgy, F.N. Rhines.

a

m

40

40

CompuTherm LLC – www.computherm.com

Types of Binary Phase Diagrams

• Isomorphous Systems

• Eutectic Systems

• Eutectoid Systems

• Peritectic Systems

• Peritectoid Systems

• Monotectic Systems

• Syntectic Systems

41

41

CompuTherm LLC – www.computherm.com

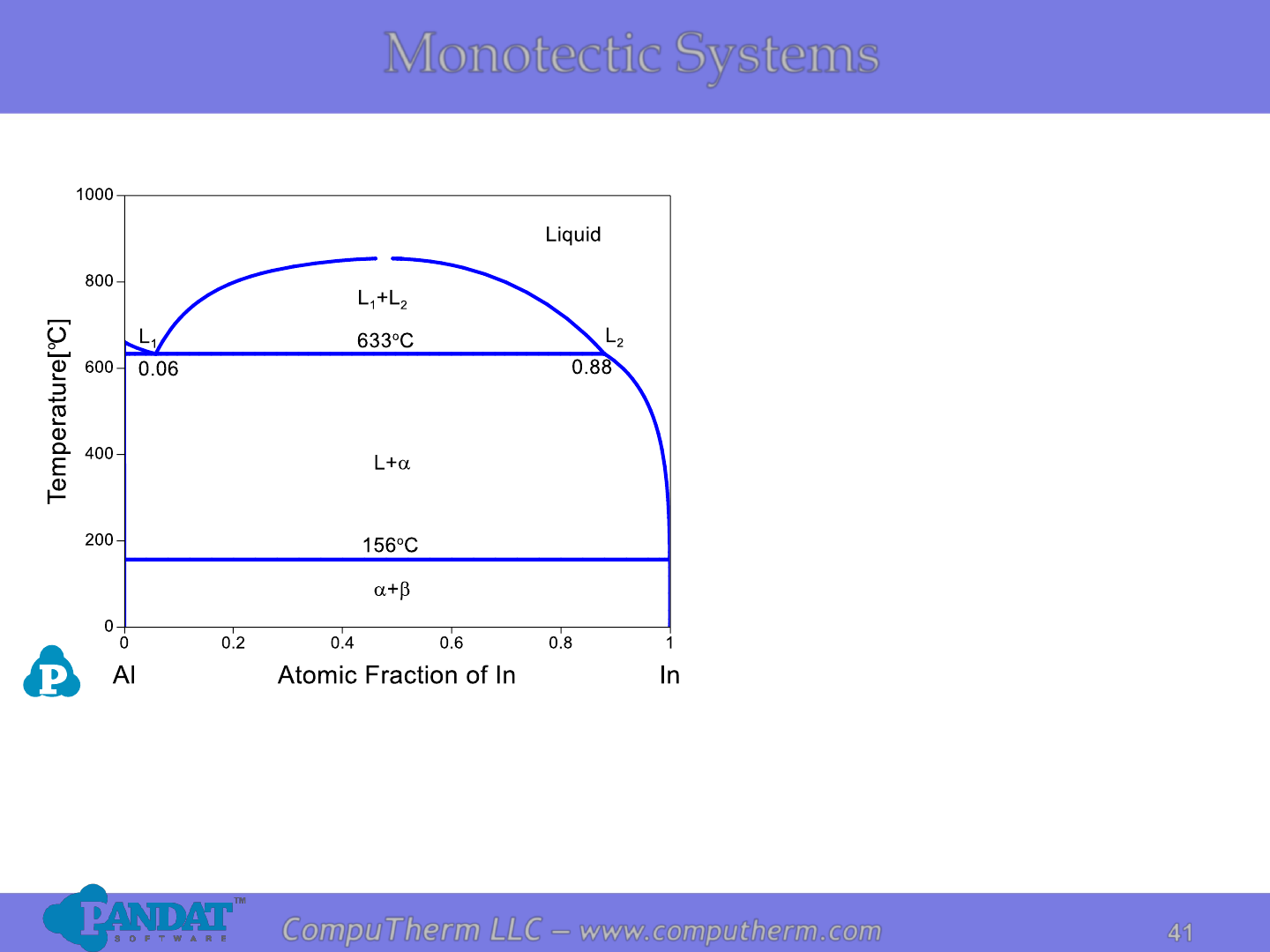

Monotectic Systems

Information from this diagram:

• Monotectic reaction occurs at

663

o

C and 6 at% In:

L

1

↔ a + L

2

.

• Alloys of all compositions start

to melt at eutectic temperature

156

o

C: L ↔ a + .

• Alloy (x

In

<6at% or x

In

>88at%)

becomes complete liquid at

liquidus.

• Alloy (6at%<x

In

<88at%)

becomes complete liquid

mixture (two liquids with

different compositions) at

663

o

C.

Details Refer to:

1. Database: Database_Monotectic_Al-In.tdb

2. Tutorial Video: Binary_Monotectic

42

42

CompuTherm LLC – www.computherm.com

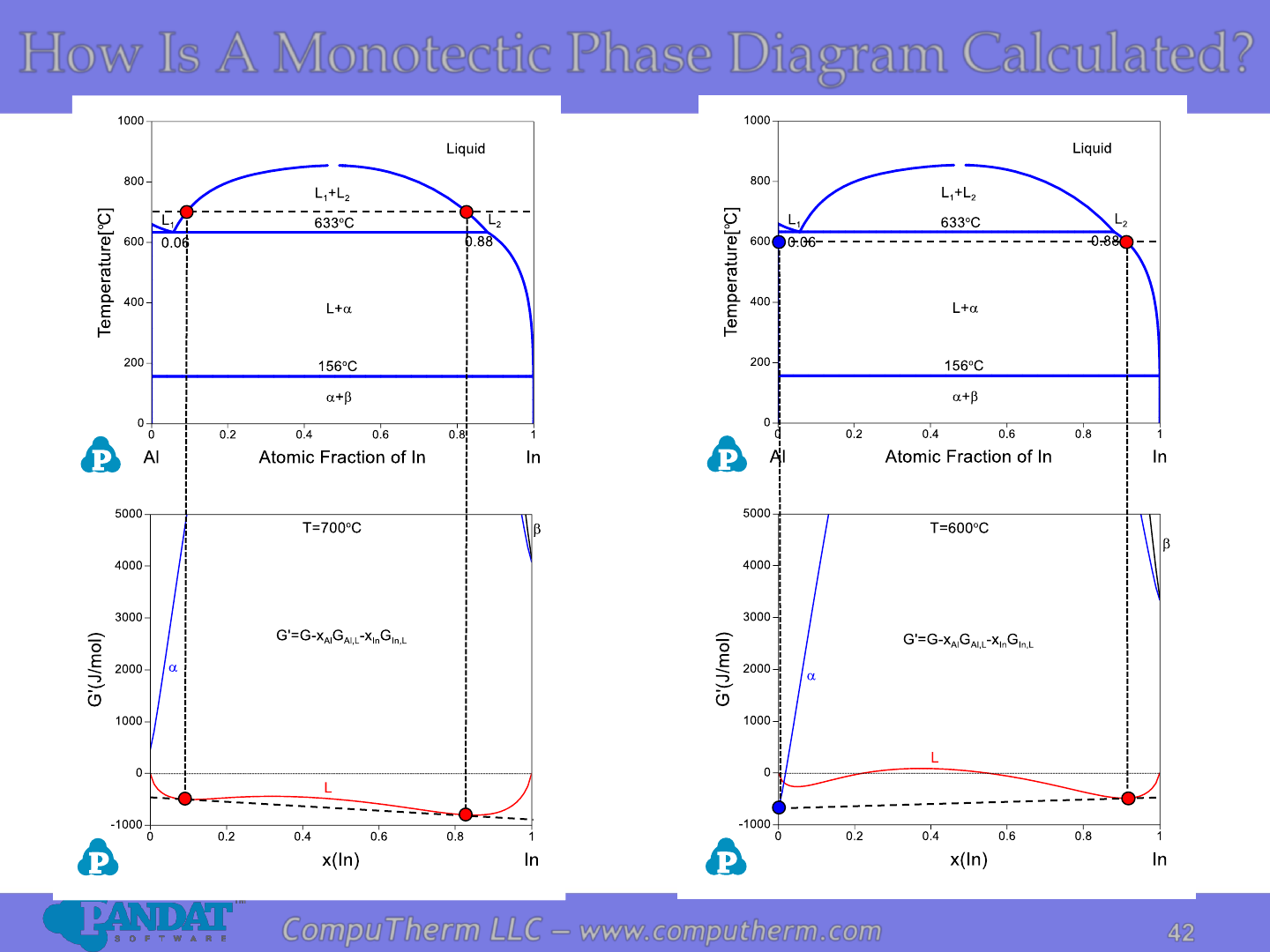

How Is A Monotectic Phase Diagram Calculated?

43

43

CompuTherm LLC – www.computherm.com

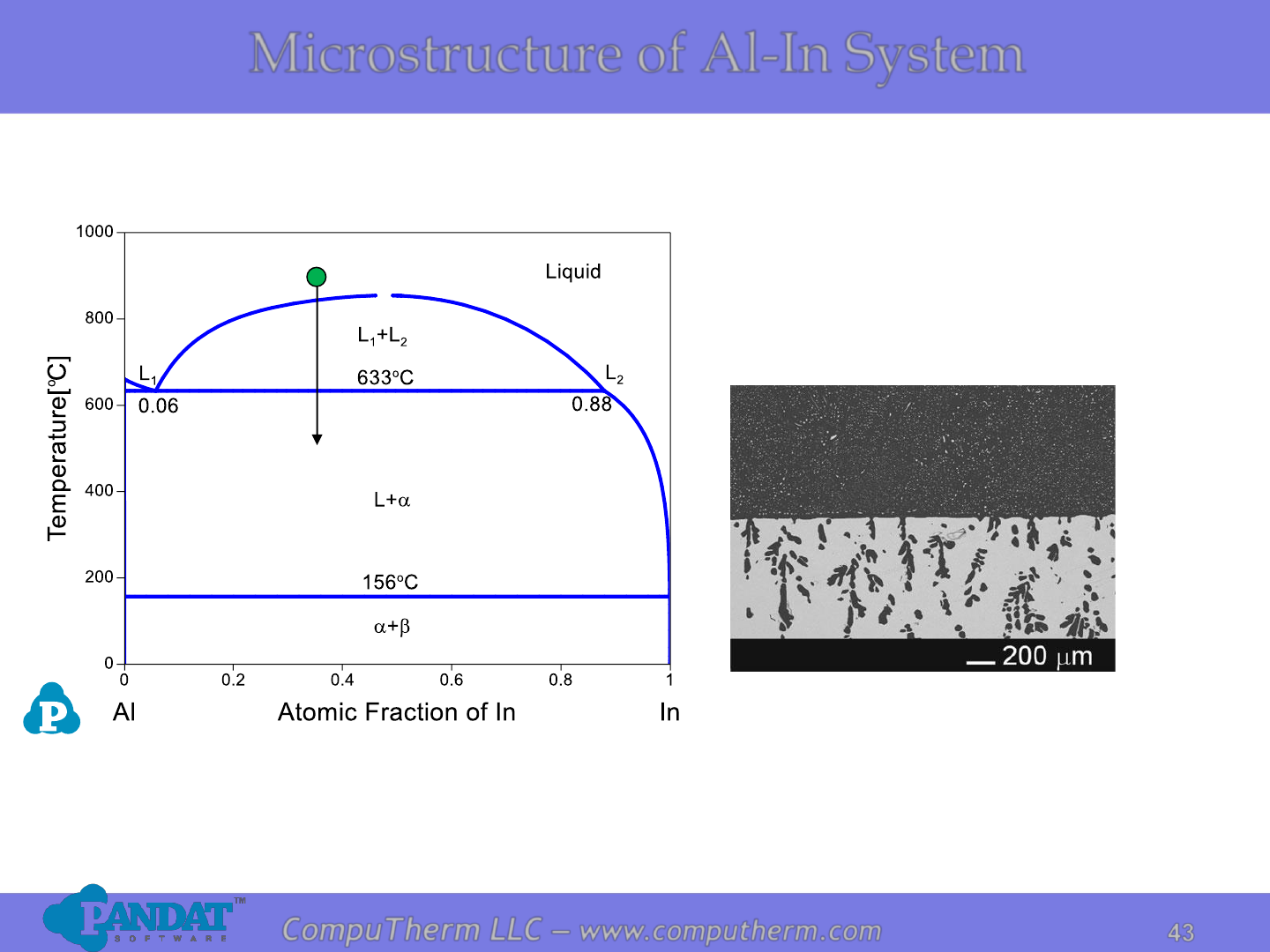

Microstructure of Al-In System

Al-rich

In-rich

Al

64

In

36

Photo from J Mater Sci (2012) 47:8360–8366.

The Al

64

In

36

(at.%) alloy in a graphite

container solidified at about 0.25 K/s

resulting in one layer on top of another.

44

44

CompuTherm LLC – www.computherm.com

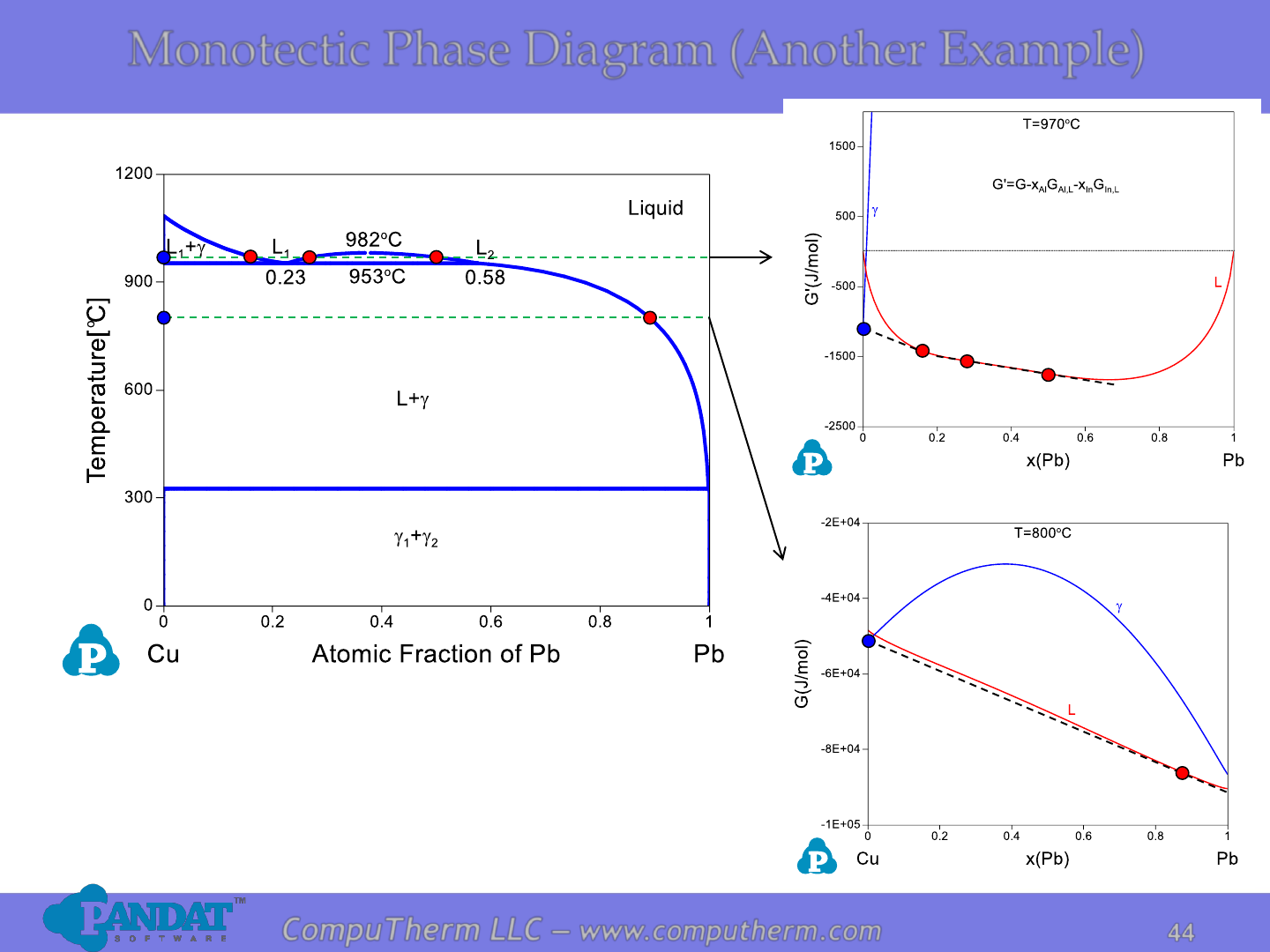

Monotectic Phase Diagram (Another Example)

Details Refer to:

1. Database: Database_Monotectic_Cu-Pb.tdb

2. Tutorial Video: Binary_Monotectic

45

45

CompuTherm LLC – www.computherm.com

Types of Binary Phase Diagrams

• Isomorphous Systems

• Eutectic Systems

• Eutectoid Systems

• Peritectic Systems

• Peritectoid Systems

• Monotectic Systems

• Syntectic Systems

46

46

CompuTherm LLC – www.computherm.com

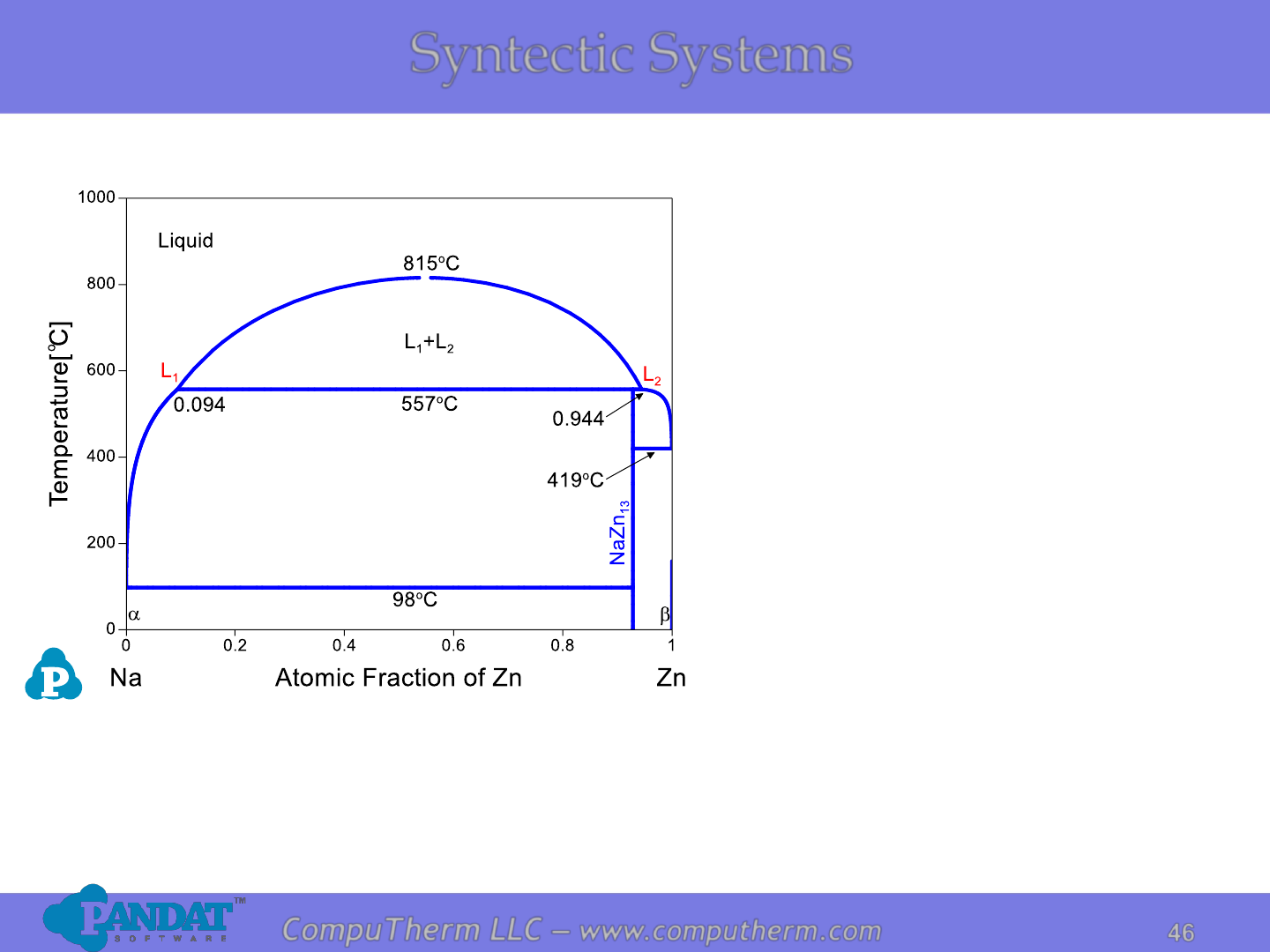

Syntectic Systems

Information from this diagram:

• Syntectic reaction occurs at

557

o

C: L

1

+ L

2

↔ NaZn

13

.

• Alloys (x

Zn

<92.3at%) start to

melt at eutectic temperature

98

o

C: L ↔ a+NaZn

13

.

• Alloys (x

Zn

>92.3at%) start to

melt at eutectic temperature

419

o

C: L ↔ +NaZn

13

.

• Alloy (x

Zn

<9.4at% or

x

Zn

>94.4at%) becomes

complete liquid at liquidus.

• Alloy (9.4at%<x

Zn

<94.4at%)

becomes complete liquid

mixture (two liquids with

different compositions) at

557

o

C.

Details Refer to:

1. Database: Database_Syntectic_Na-Zn.tdb

2. Tutorial Video: Binary_Syntectic

47

47

CompuTherm LLC – www.computherm.com

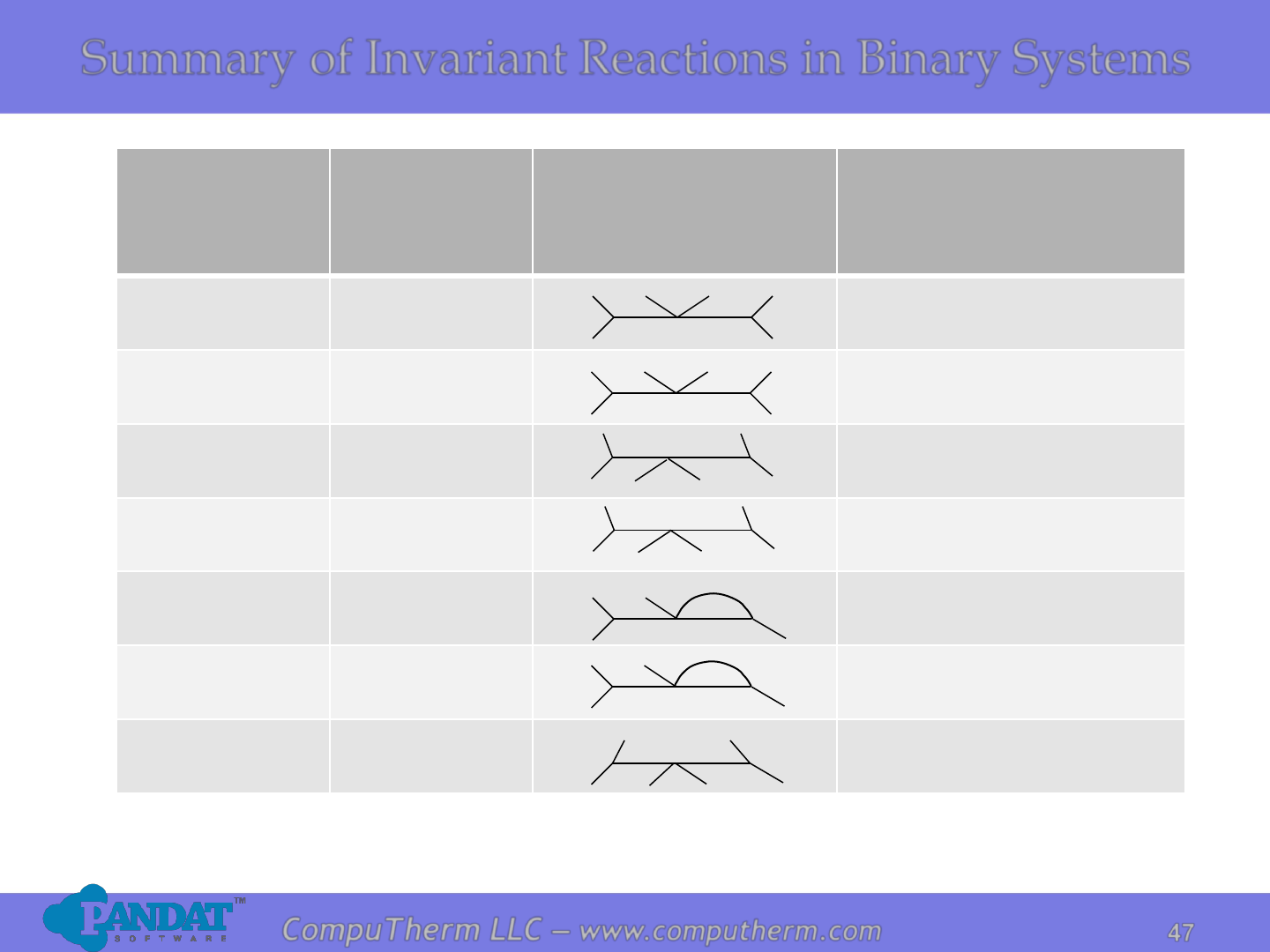

Reaction

Symbolic

equation

Schematic

presentation

Example

Eutectic

L↔

α+ β

Cu

-Ag, Pb-Sn, Al-Si

Eutectoid

α↔β+ γ

Fe

-C

Peritectic

L+

α↔β

Cu

-Fe, Pb-In

Peritectoid

α+ β↔γ

Al

-Cu

Monotectic

L

1

↔L

2

+ α

Cu

-Pb, Al-In

Monotectoid

α

1

↔α

2

+ β

Al

-Zn

Syntectic

L

1

+ L

2

↔α

Na

-Zn

L

a

a

g

L

a

a

g

a

L

2

L

1

a

L

2

L

1

Summary of Invariant Reactions in Binary Systems

a

2

a

1

48

48

CompuTherm LLC – www.computherm.com

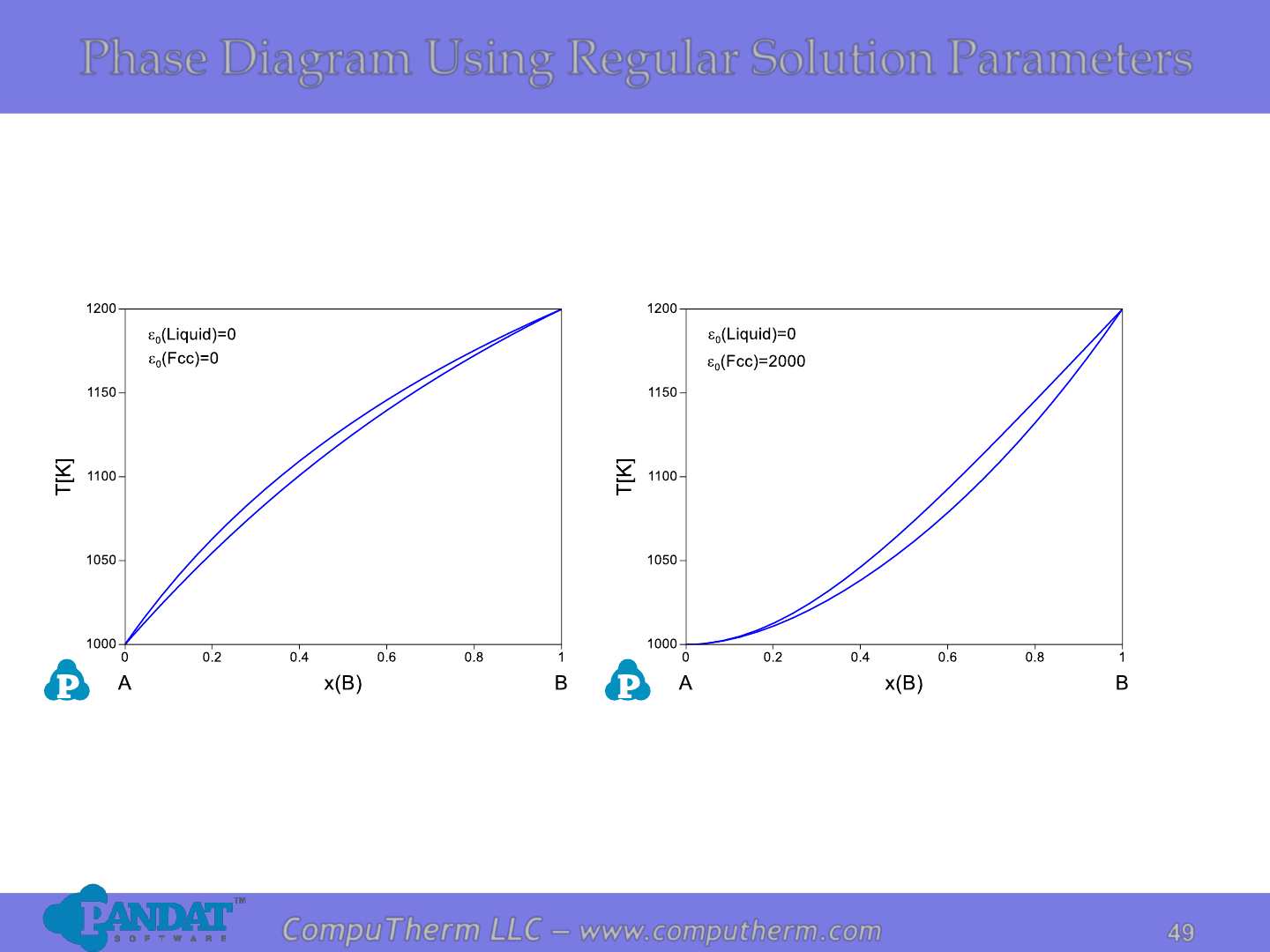

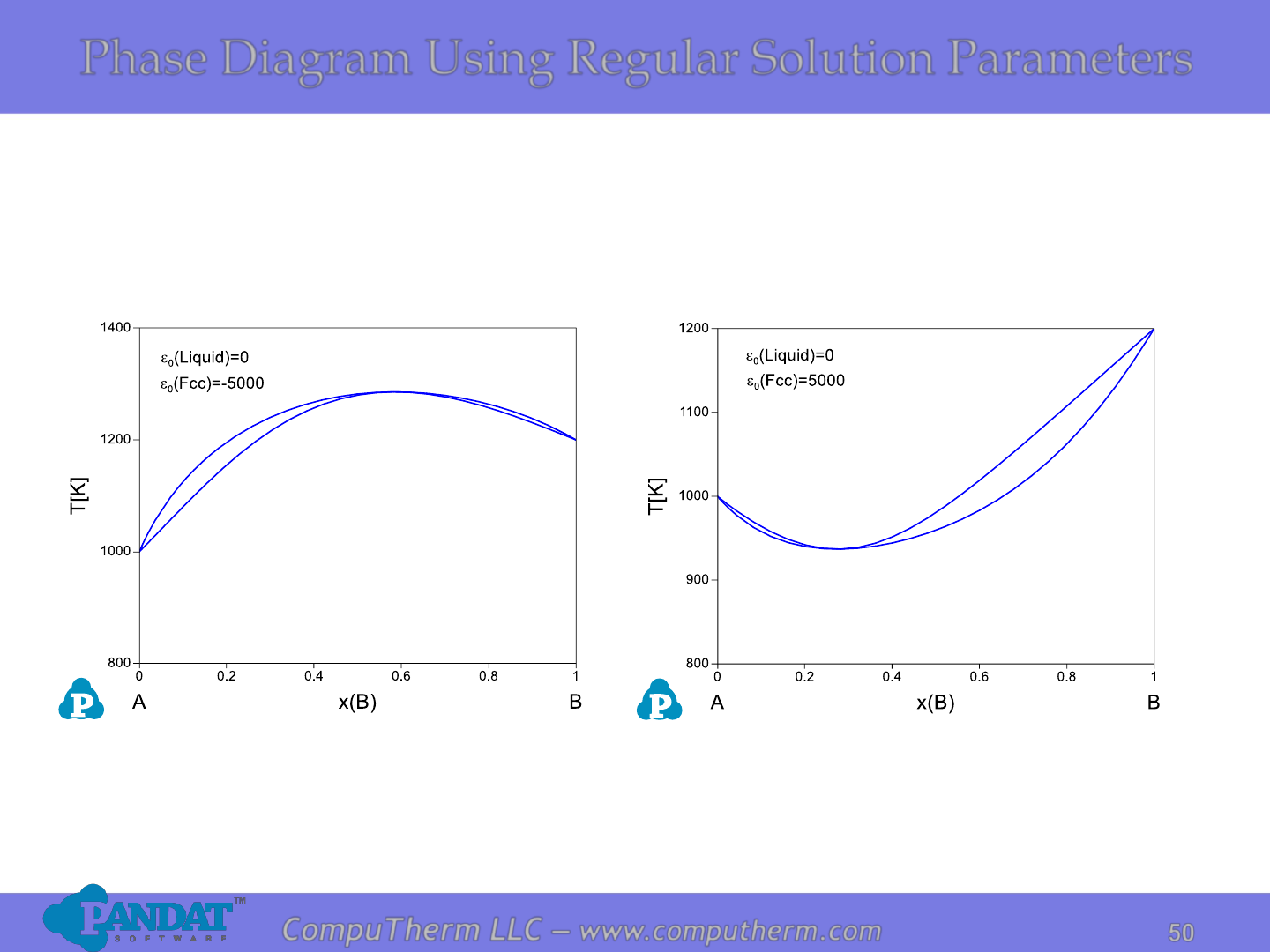

Binary Phase Diagrams

Use of regular solution model parameters to

generate different types of binary phase diagram

•Hypothetical elements A and B both present Fcc (a) structure in

their solid states.

•Both liquid and solid phases are described using regular solution

models.

( )

LL

B

L

A

L

B

L

B

L

A

L

A

L

B

L

B

L

A

L

A

L

xxxxxxRTGxGxG

0

,o,o

lnln

++++=

( )

aaaaaaaaaaa

0

,o,o

lnln

BABBAAB

L

BAA

xxxxxxRTGxGxG ++++=

49

49

CompuTherm LLC – www.computherm.com

Phase Diagram Using Regular Solution Parameters

50

50

CompuTherm LLC – www.computherm.com

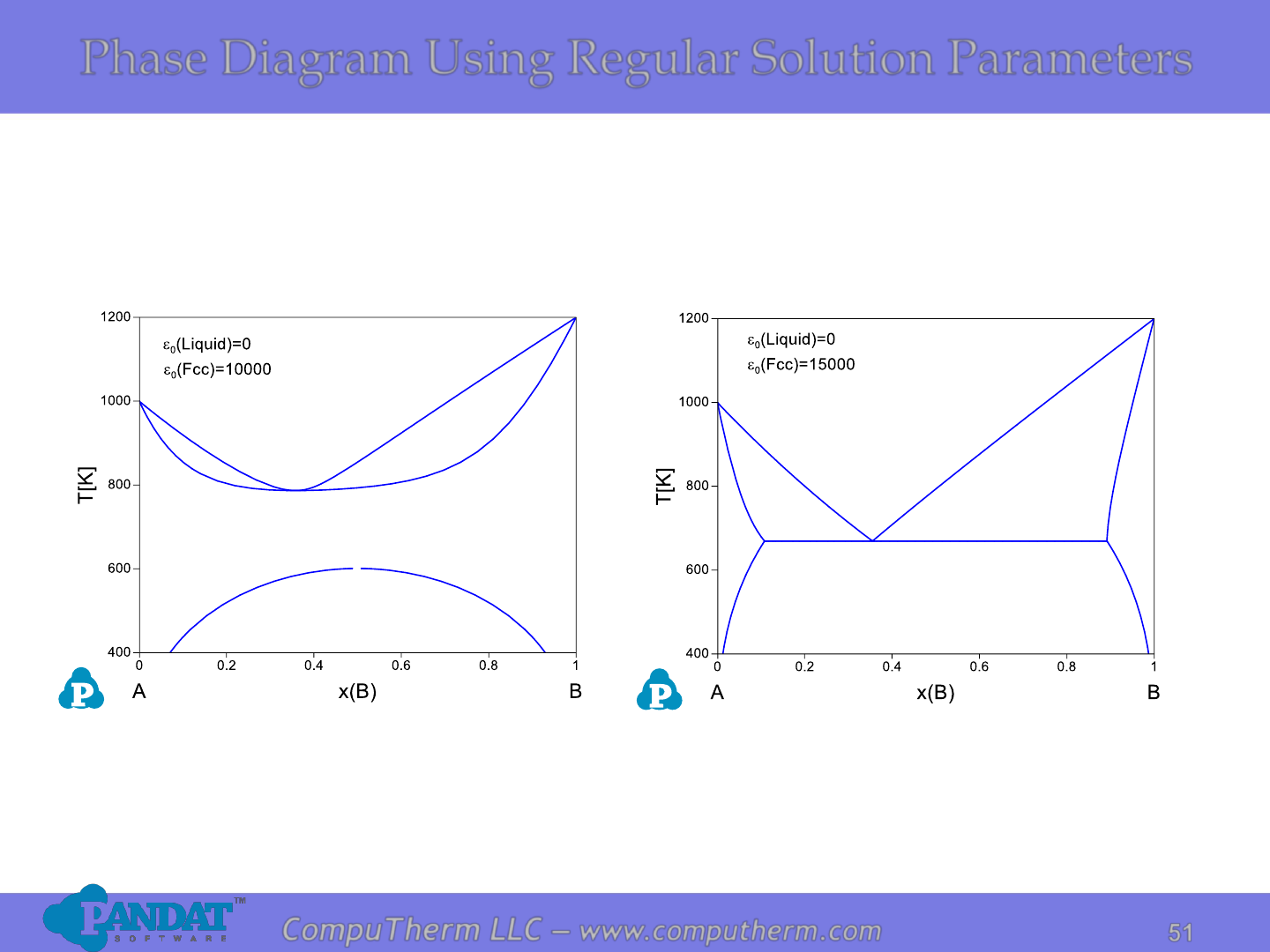

Phase Diagram Using Regular Solution Parameters

51

51

CompuTherm LLC – www.computherm.com

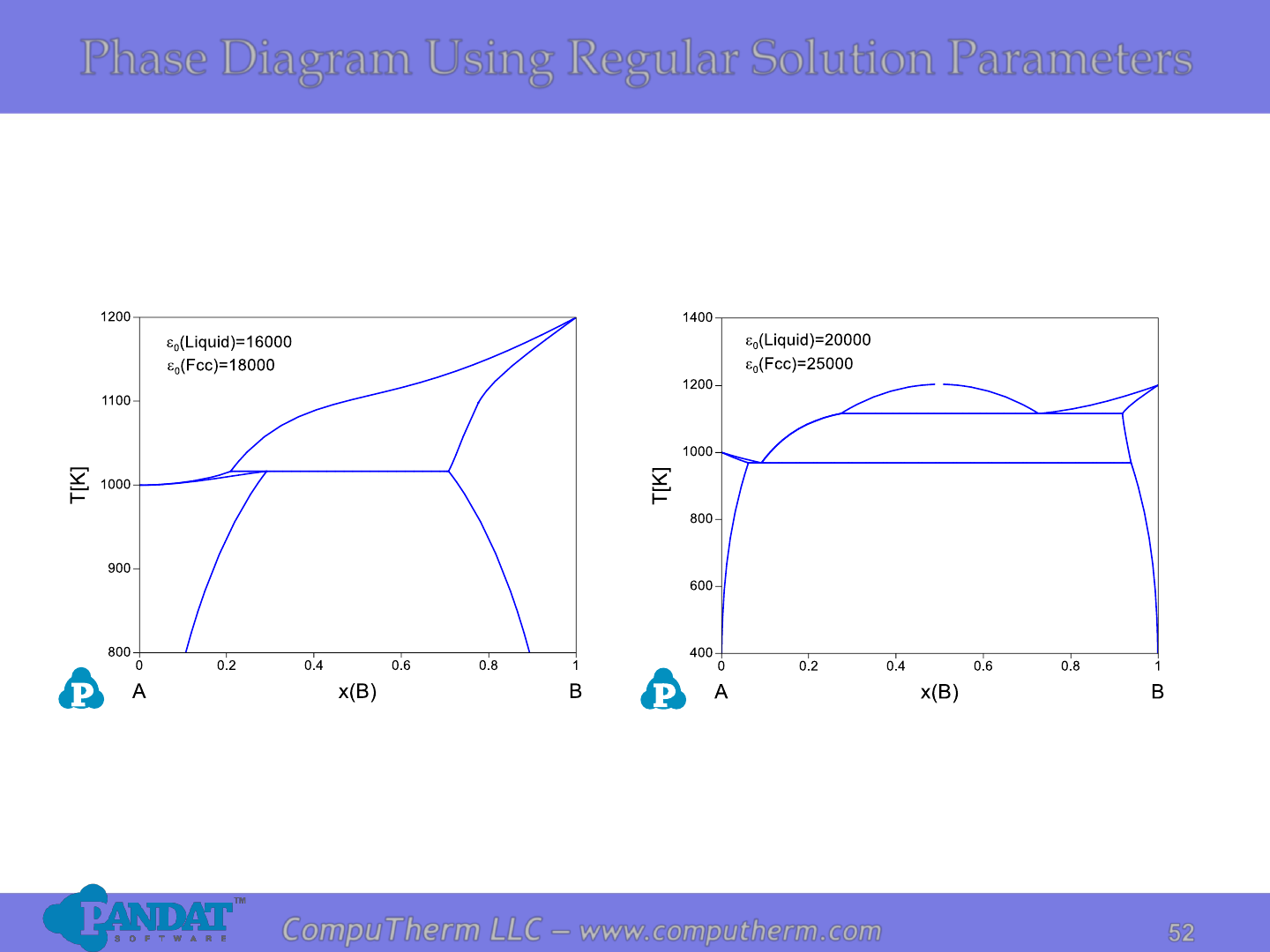

Phase Diagram Using Regular Solution Parameters

52

52

CompuTherm LLC – www.computherm.com

Phase Diagram Using Regular Solution Parameters

53

53

CompuTherm LLC – www.computherm.com

Acknowledgement

• Many of the slides are reproduced based on the

book: Materials Science and Engineering: An

Introduction, 8

th

Edition, William D. Callister, Jr.

David G. Rethwisch.

54

54

CompuTherm LLC – www.computherm.com

For Download

• The PowerPoint file and related thermodynamic

database files are available for downloading

under the directory: Resources/Downloads.

• Thank you for your interest.