MSAE 530

Binary Phase Diagram I

2

Overview of this lecture

• How to define phase equilibrium?

• Characteristics of miscibility gap

• Characteristics of regular solution at critical

temperature

• Examples of real solutions

• Gibbs’ Phase Rule

3

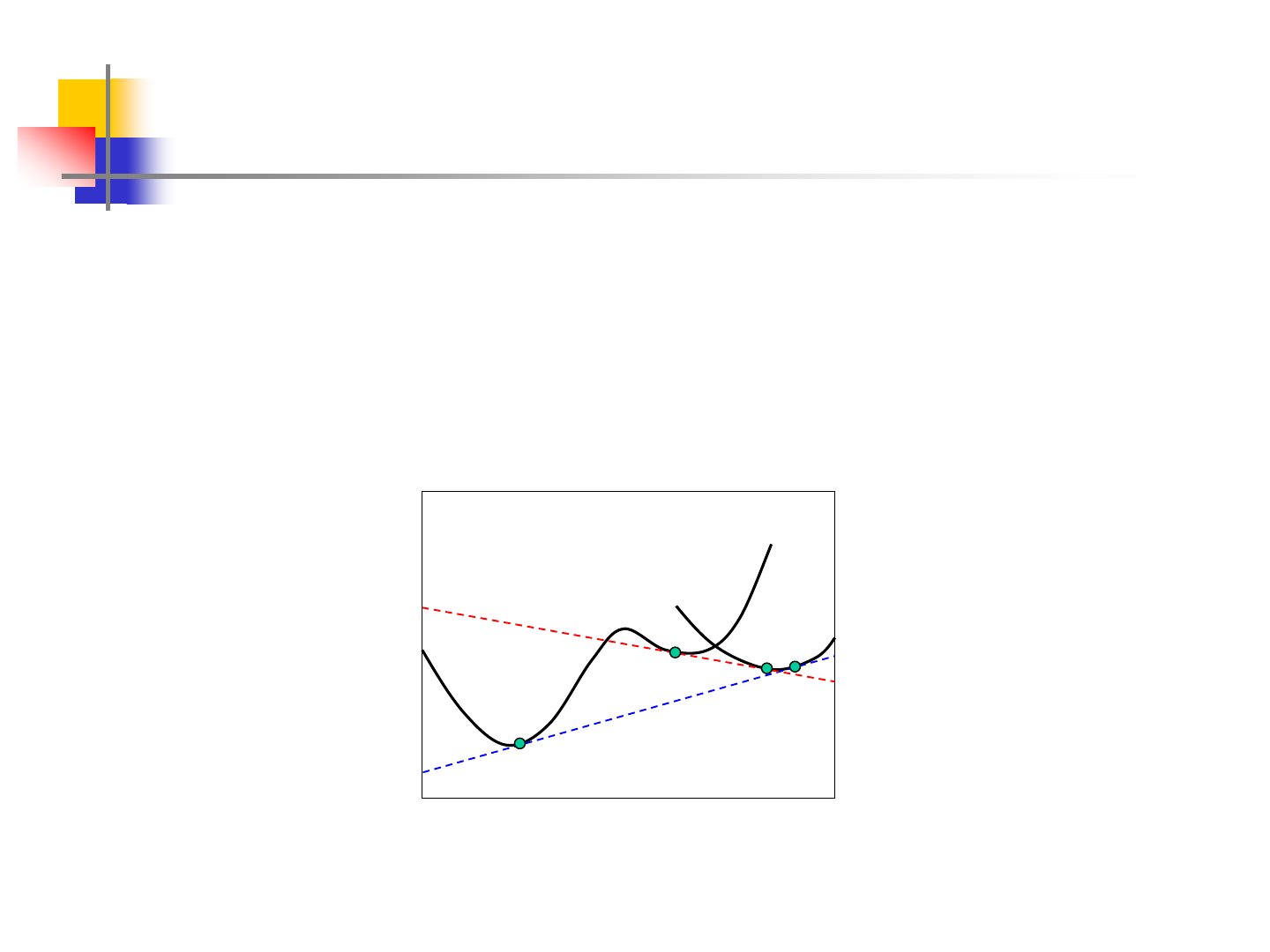

Introduction

A minimum in G, in the case of a mixture of phases, corresponds

with the equilibrium condition given by:

components allfor

III

i

II

i

I

i

==

I

II

A B

mol fracn. B

G

a

b

c

d

4

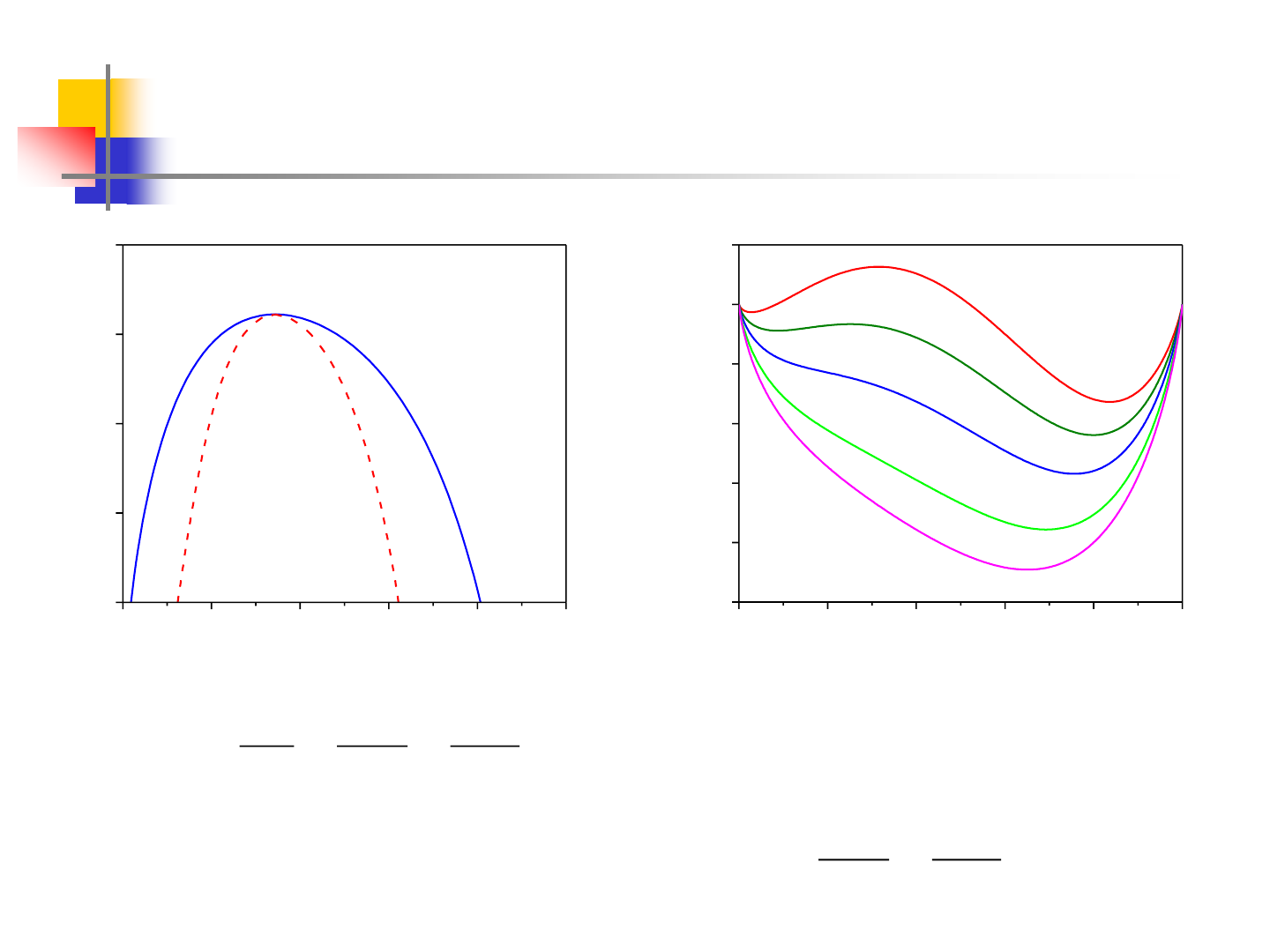

Miscibility Gap

0.0 0.2 0.4 0.6 0.8 1.0

300

400

500

600

700

800

900

critical point

1

+

2

2

1

=12500 J/mol

B

A

T(K)

x

B

metastable

metastable

Spinodal line

unstable

5

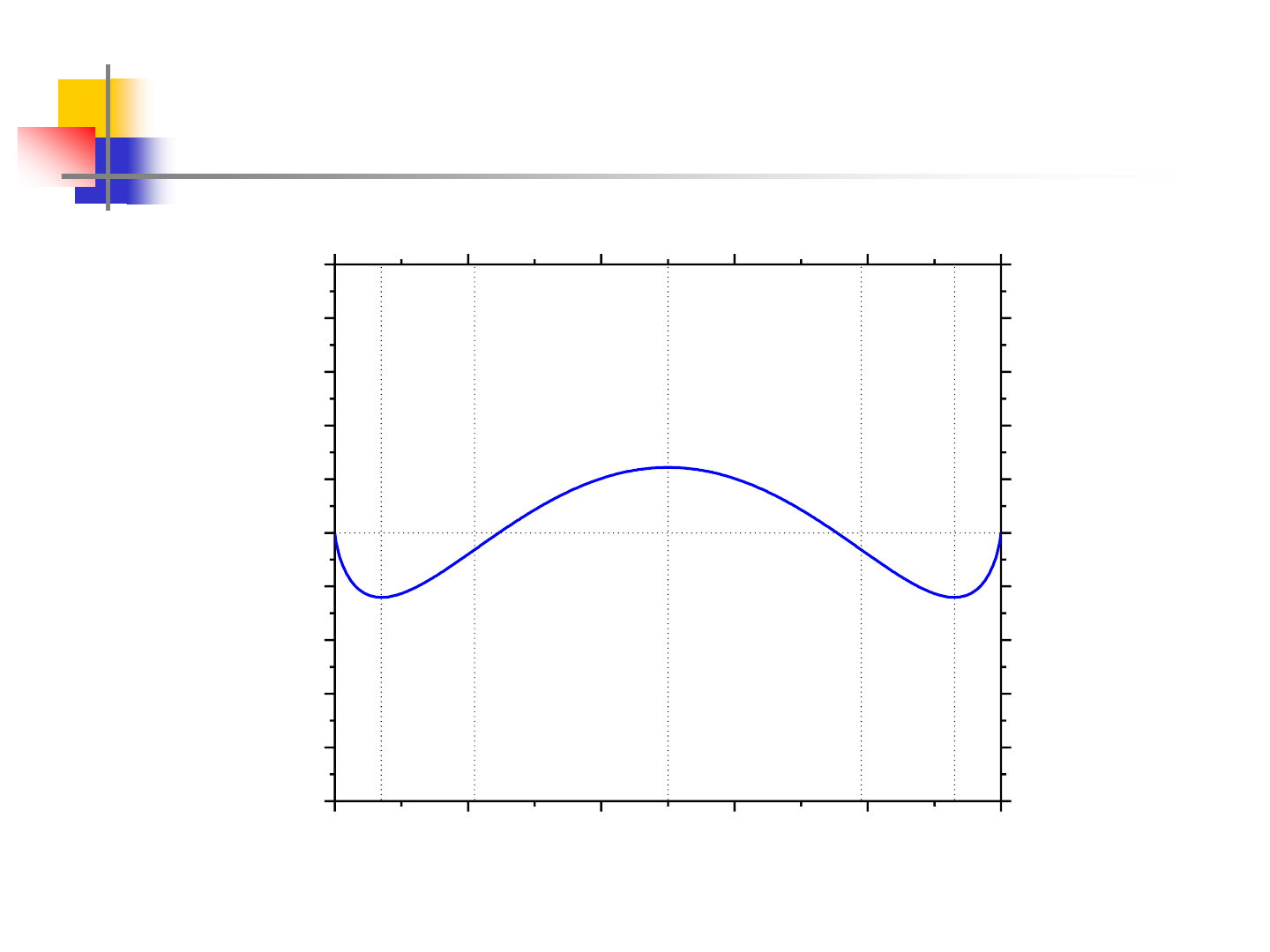

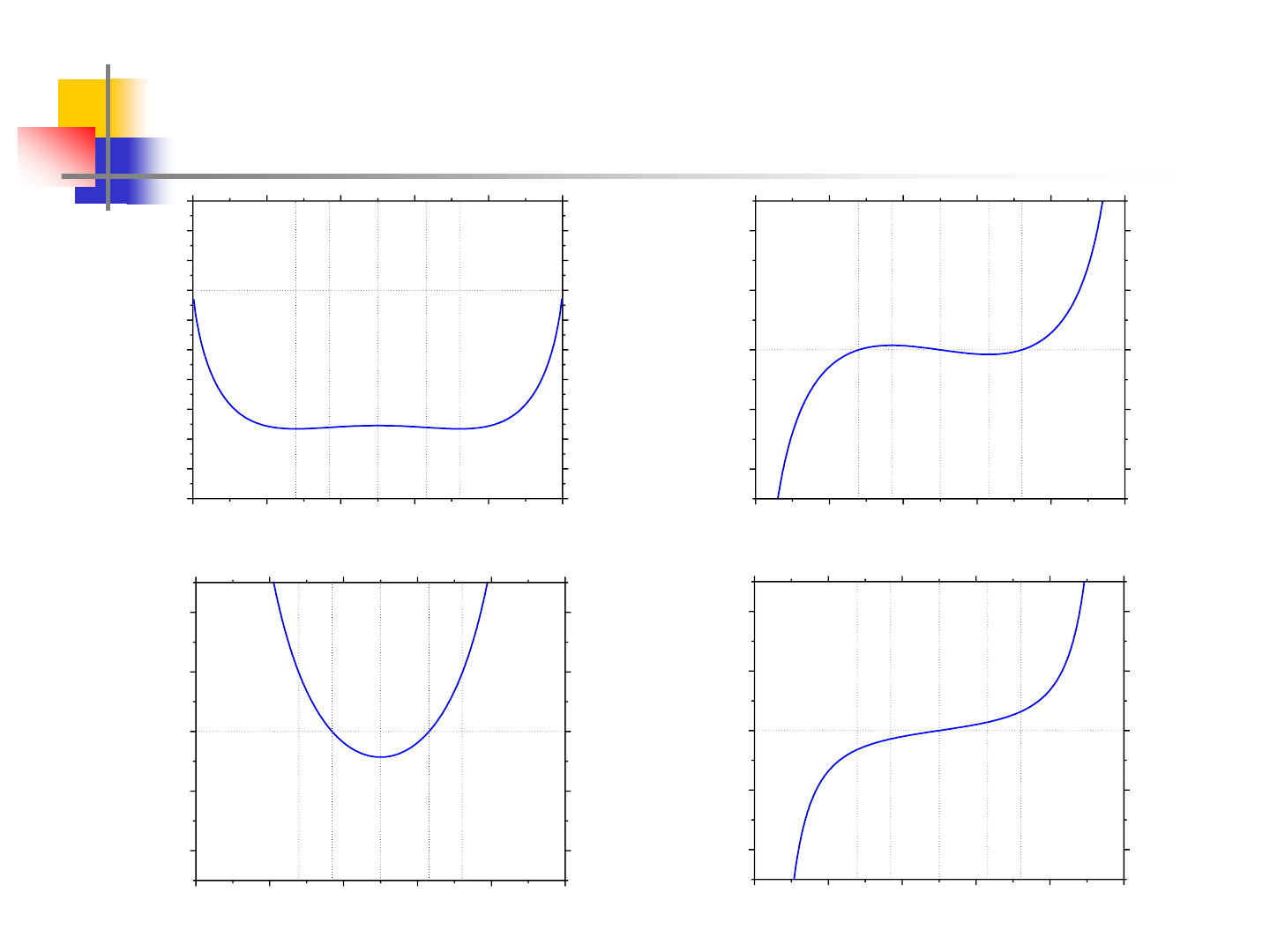

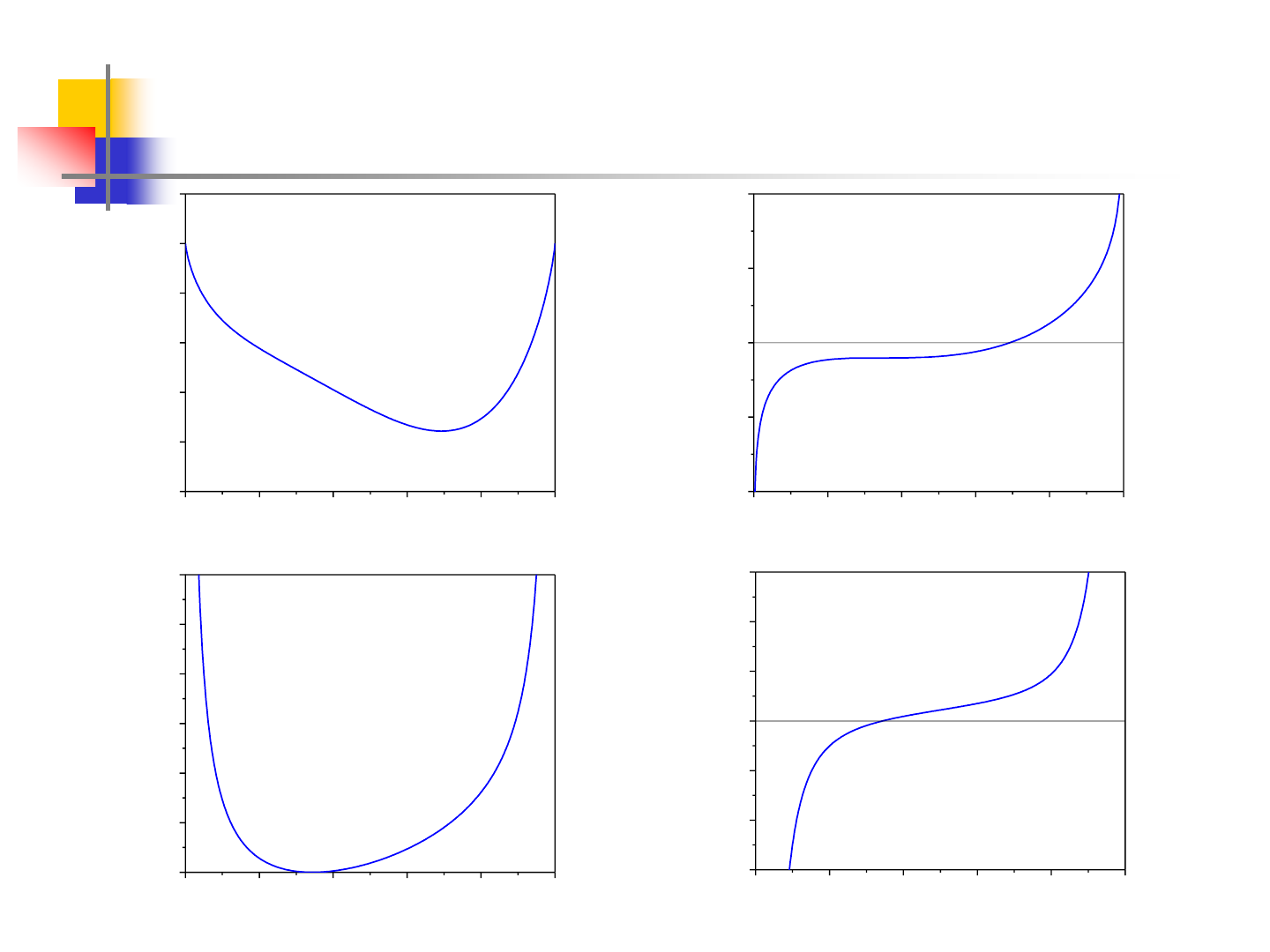

Miscibility Gap at 500K

0.0 0.2 0.4 0.6 0.8 1.0

-1.0

-0.8

-0.6

-0.4

-0.2

0.0

0.2

0.4

0.6

0.8

1.0

0.0 0.2 0.4 0.6 0.8 1.0

-1.0

-0.8

-0.6

-0.4

-0.2

0.0

0.2

0.4

0.6

0.8

1.0

e

d

c

b

a

T=500K

B

A

G(kJ/mol)

X

2

6

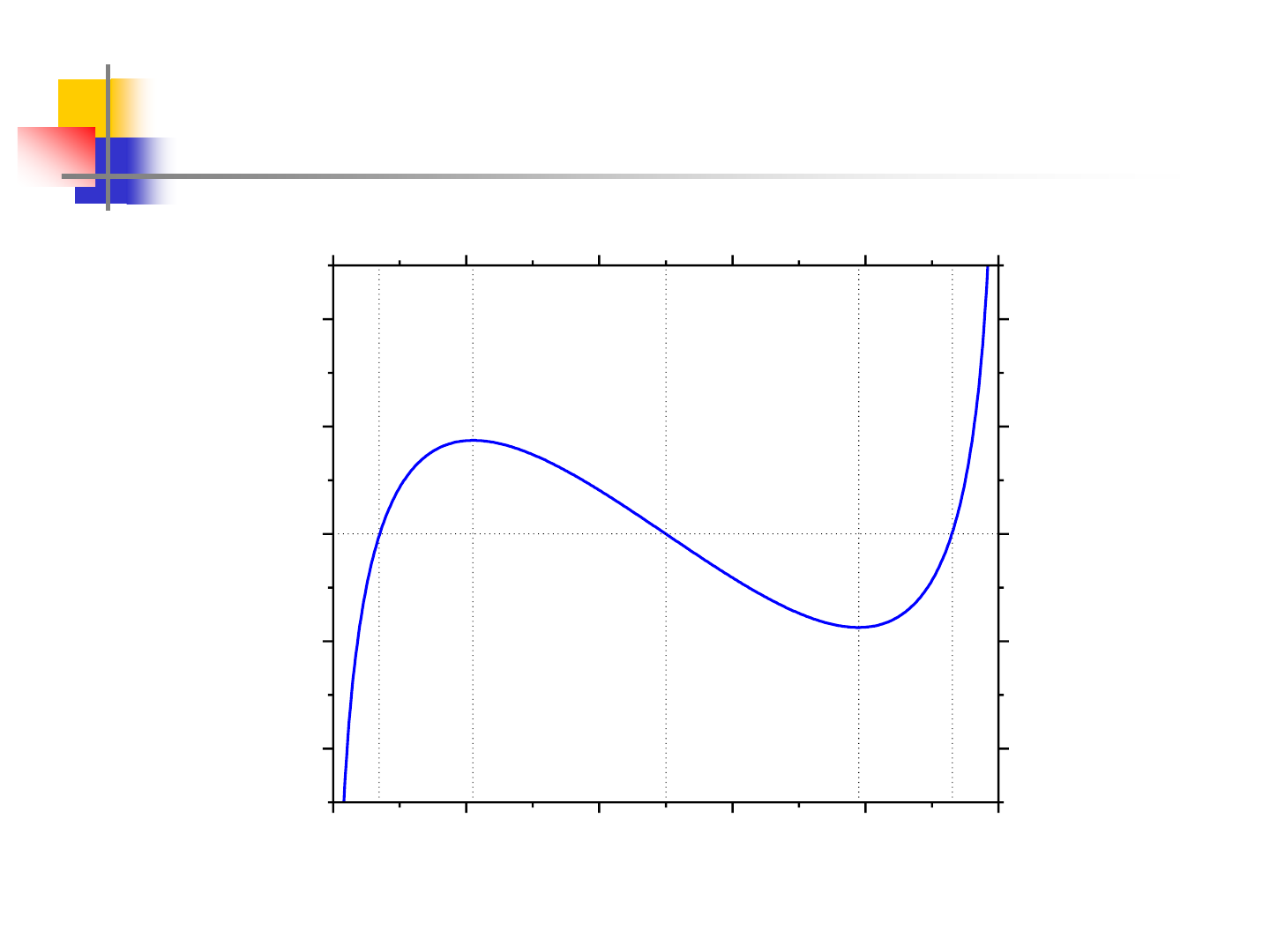

Miscibility Gap at 500K

0.0 0.2 0.4 0.6 0.8 1.0

-4

-2

0

2

4

0.0 0.2 0.4 0.6 0.8 1.0

-4

-2

0

2

4

ed

c

b

a

B

A

T=500K

dG/dx (kJ/mol)

x

2

7

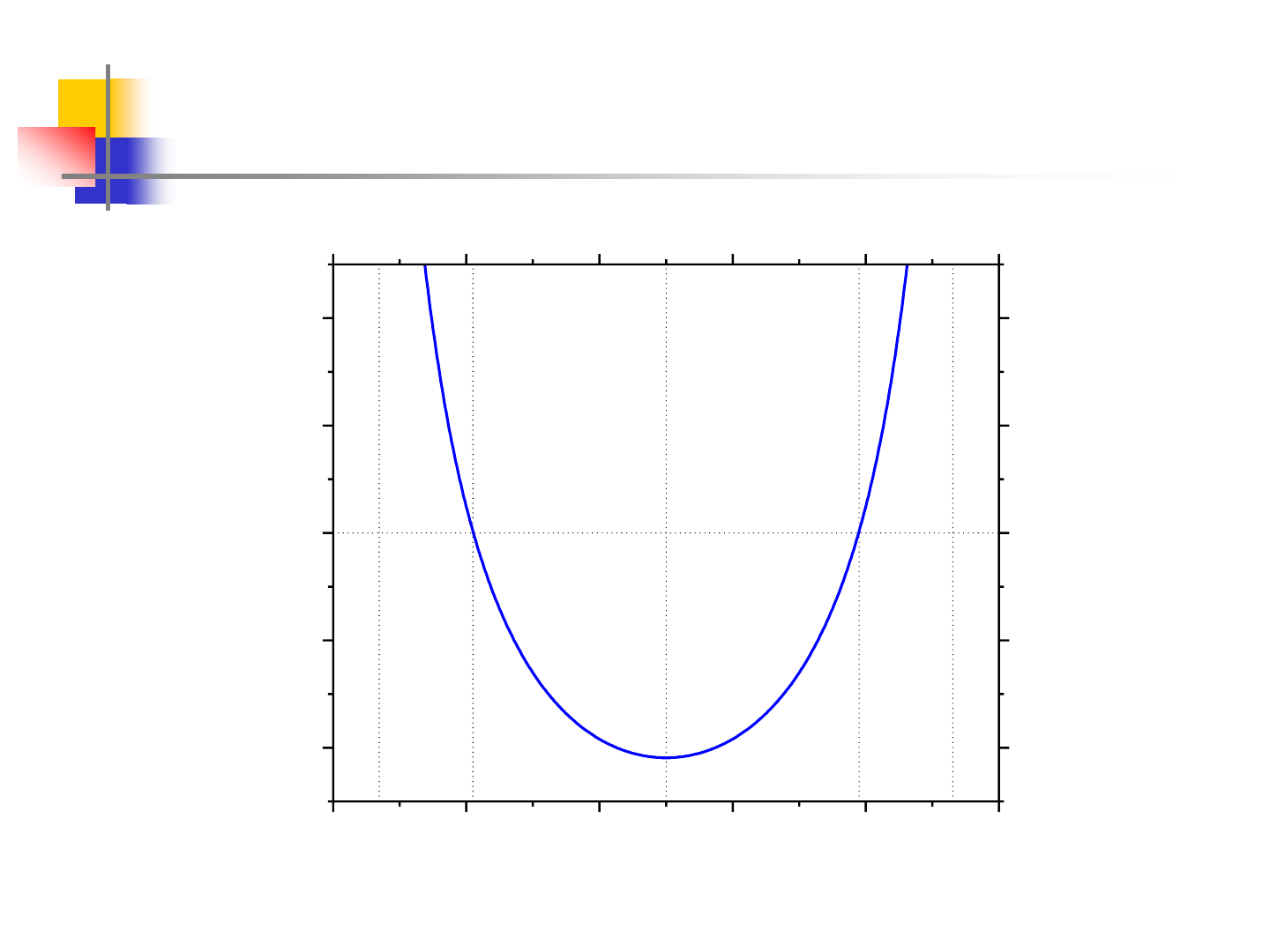

Miscibility Gap at 500K

0.0 0.2 0.4 0.6 0.8 1.0

-8

-4

0

4

8

0.0 0.2 0.4 0.6 0.8 1.0

-8

-4

0

4

8

T=500K

e

b

c d

a

B

A

d

2

G/dx

2

(kJ/mol)

x

2

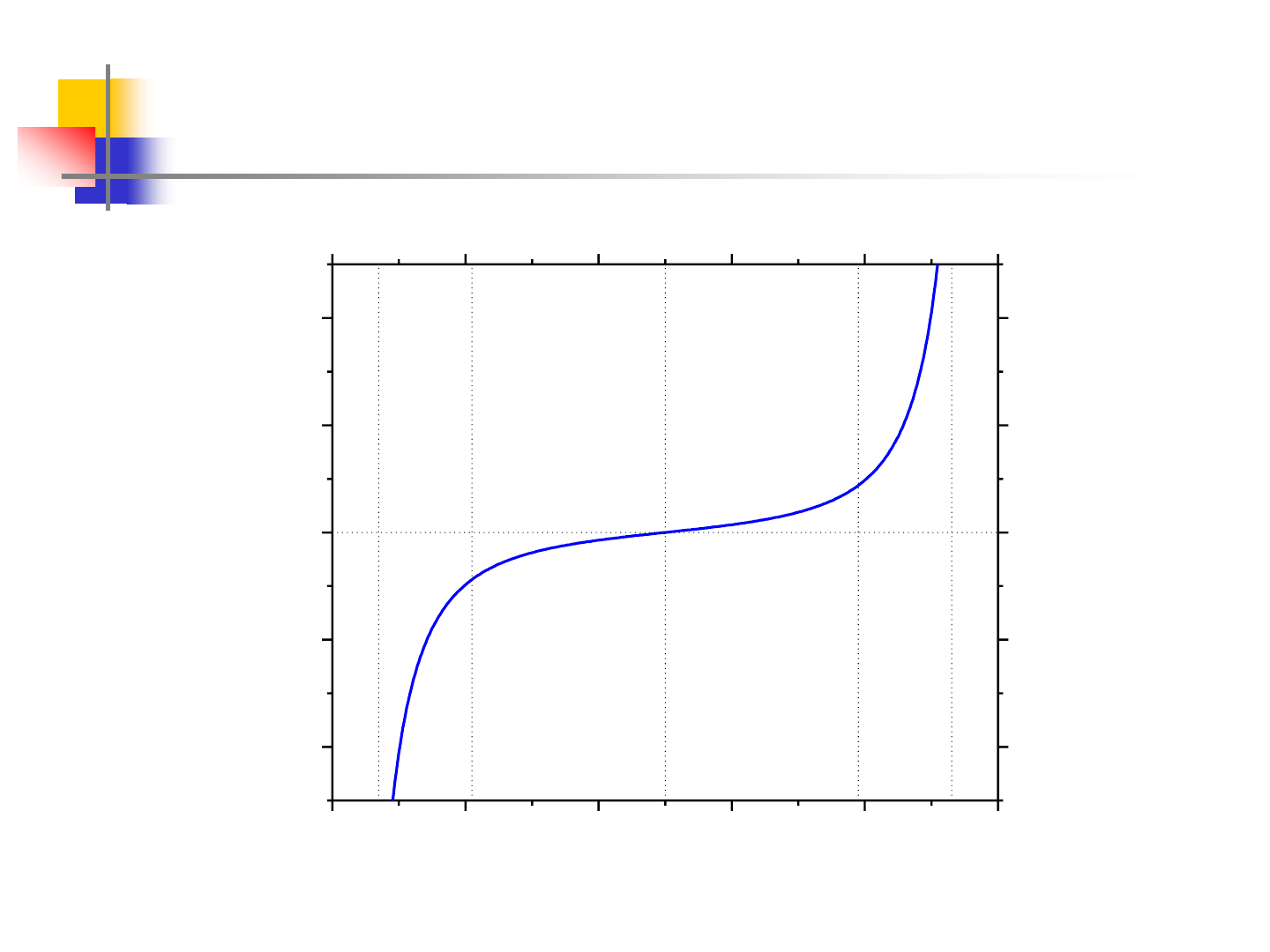

8

Miscibility Gap at 500K

0.0 0.2 0.4 0.6 0.8 1.0

-400

-200

0

200

400

0.0 0.2 0.4 0.6 0.8 1.0

-400

-200

0

200

400

b

c d

e

a

T=500K

B

A

d

3

G/dx

3

(kJ/mol)

x

2

9

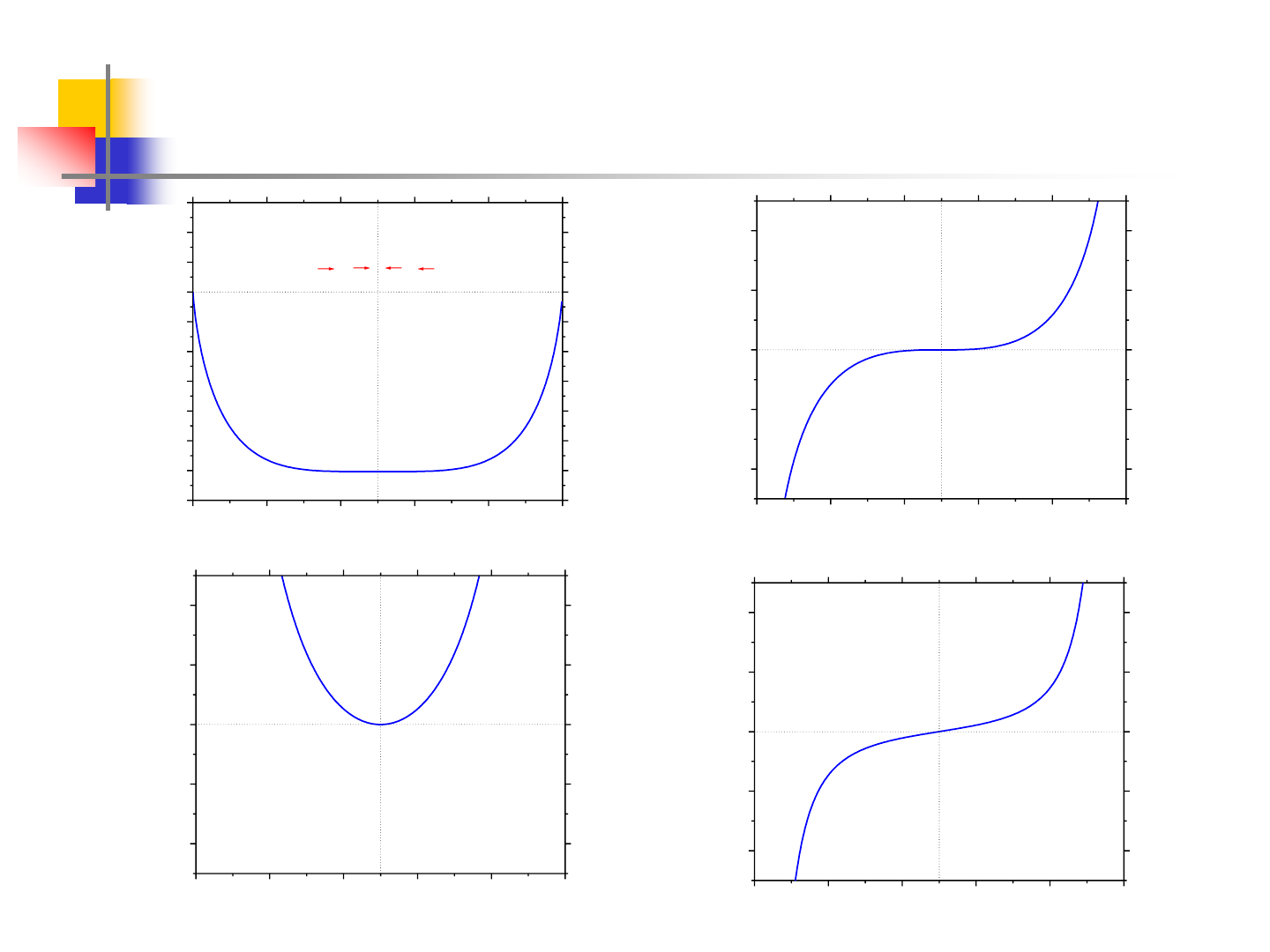

Miscibility Gap at 700K

0.0 0.2 0.4 0.6 0.8 1.0

-1.4

-1.2

-1.0

-0.8

-0.6

-0.4

-0.2

0.0

0.2

0.4

0.6

0.0 0.2 0.4 0.6 0.8 1.0

-1.4

-1.2

-1.0

-0.8

-0.6

-0.4

-0.2

0.0

0.2

0.4

0.6

e

d

c

b

a

T=700K

B

A

G(kJ/mol)

X

2

0.0 0.2 0.4 0.6 0.8 1.0

-4

-2

0

2

4

0.0 0.2 0.4 0.6 0.8 1.0

-4

-2

0

2

4

e

d

c

b

a

B

A

T=700K

dG/dx (kJ/mol)

x

2

0.0 0.2 0.4 0.6 0.8 1.0

-8

-4

0

4

8

0.0 0.2 0.4 0.6 0.8 1.0

-8

-4

0

4

8

T=700K

e

b

c d

a

B

A

d

2

G/dx

2

(kJ/mol)

x

2

0.0 0.2 0.4 0.6 0.8 1.0

-400

-200

0

200

400

0.0 0.2 0.4 0.6 0.8 1.0

-400

-200

0

200

400

b

c d ea

T=700K

B

A

d

3

G/dx

3

(kJ/mol)

x

2

10

Miscibility Gap at 751.7K

0.0 0.2 0.4 0.6 0.8 1.0

-1.4

-1.2

-1.0

-0.8

-0.6

-0.4

-0.2

0.0

0.2

0.4

0.6

0.0 0.2 0.4 0.6 0.8 1.0

-1.4

-1.2

-1.0

-0.8

-0.6

-0.4

-0.2

0.0

0.2

0.4

0.6

e

d

c

b

a

T=Tc=751.7K

B

A

G(kJ/mol)

X

2

0.0 0.2 0.4 0.6 0.8 1.0

-4

-2

0

2

4

0.0 0.2 0.4 0.6 0.8 1.0

-4

-2

0

2

4

T=Tc=751.7K

B

A

dG/dx (kJ/mol)

x

2

0.0 0.2 0.4 0.6 0.8 1.0

-8

-4

0

4

8

0.0 0.2 0.4 0.6 0.8 1.0

-8

-4

0

4

8

T=Tc=751.7K

B

A

d

2

G/dx

2

(kJ/mol)

x

2

0.0 0.2 0.4 0.6 0.8 1.0

-400

-200

0

200

400

0.0 0.2 0.4 0.6 0.8 1.0

-400

-200

0

200

400

T=Tc=751.7K

B

A

d

3

G/dx

3

(kJ/mol)

x

2

11

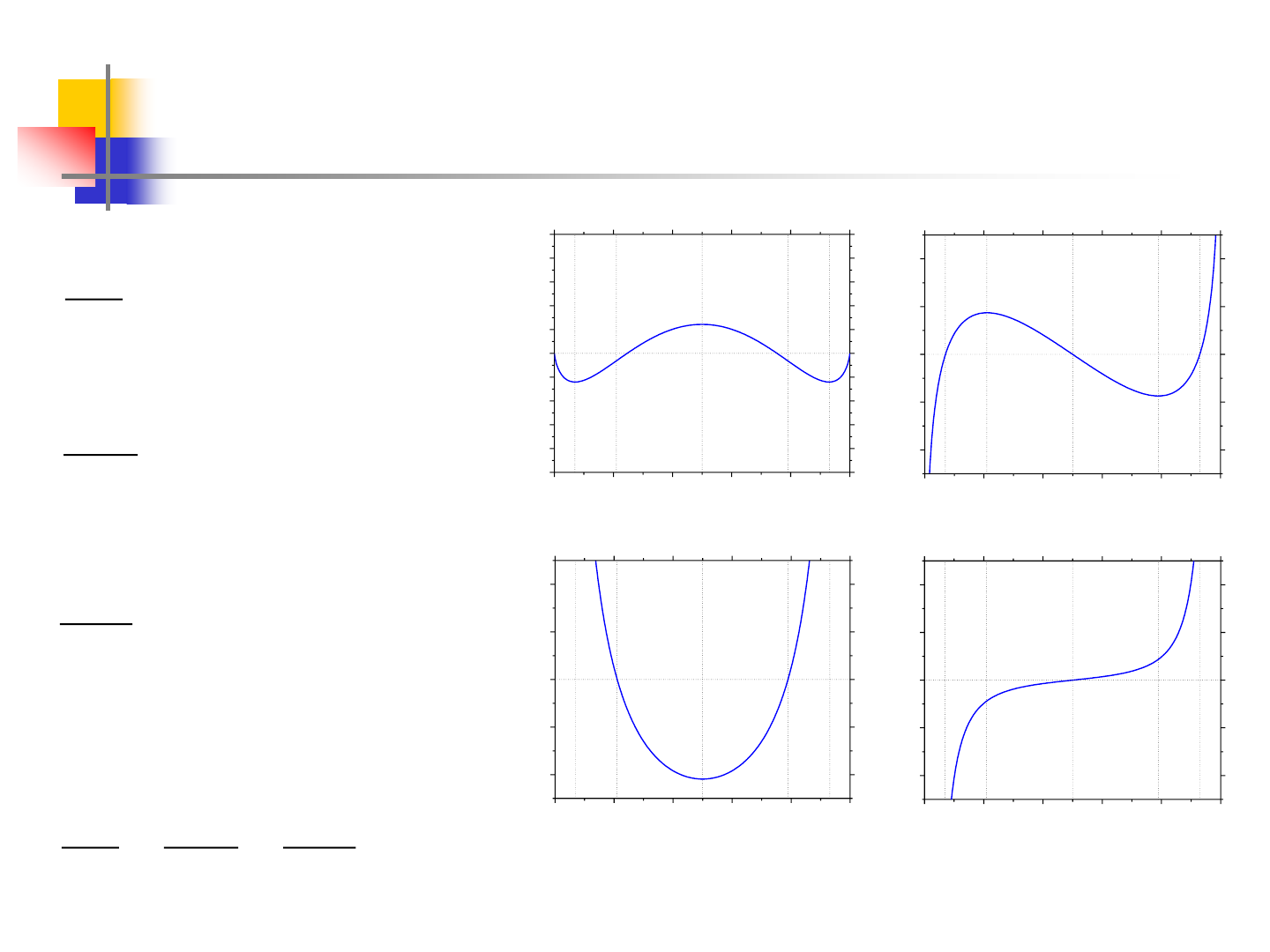

Miscibility Gap - Regular Solution

0.0 0.2 0.4 0.6 0.8 1.0

-1.0

-0.8

-0.6

-0.4

-0.2

0.0

0.2

0.4

0.6

0.8

1.0

0.0 0.2 0.4 0.6 0.8 1.0

-1.0

-0.8

-0.6

-0.4

-0.2

0.0

0.2

0.4

0.6

0.8

1.0

e

d

c

b

a

T=500K

B

A

G(kJ/mol)

X

2

0.0 0.2 0.4 0.6 0.8 1.0

-4

-2

0

2

4

0.0 0.2 0.4 0.6 0.8 1.0

-4

-2

0

2

4

ed

c

b

a

B

A

T=500K

dG/dx (kJ/mol)

x

2

0.0 0.2 0.4 0.6 0.8 1.0

-8

-4

0

4

8

0.0 0.2 0.4 0.6 0.8 1.0

-8

-4

0

4

8

T=500K

e

b

c d

a

B

A

d

2

G/dx

2

(kJ/mol)

x

2

0.0 0.2 0.4 0.6 0.8 1.0

-400

-200

0

200

400

0.0 0.2 0.4 0.6 0.8 1.0

-400

-200

0

200

400

b

c d

e

a

T=500K

B

A

d

3

G/dx

3

(kJ/mol)

x

2

eca

x, x,at x 0

dx

dG

=

db

2

2

x,at x 0

dx

Gd

=

c

3

3

at x 0

dx

Gd

=

c

3

3

2

2

C

at x 0

dx

Gd

dx

Gd

dx

dG

TT as

===

→

12

Miscibility Gap – Regular Solution

id

TSx)1εx(G −−=

x1

x

lnRTx)21ε(

dx

dG

−

+−=

−

++−=

x1

1

x

1

RTε2

dx

Gd

2

2

223

3

)x1(x

1x2

RT

dx

Gd

−

−

=

At T = T

C

, x = x

C

0

)x1(x

1x2

,0

dx

Gd

2

C

2

C

C

3

3

=

−

−

=

X

C

= 0.5

−

+==

CC

C

2

2

x1

1

x

1

RT2 ,0

dx

Gd

= 2RT

C

phases! existing-co theof nscompositio obtain the toused becan 0

dx

dG

=

13

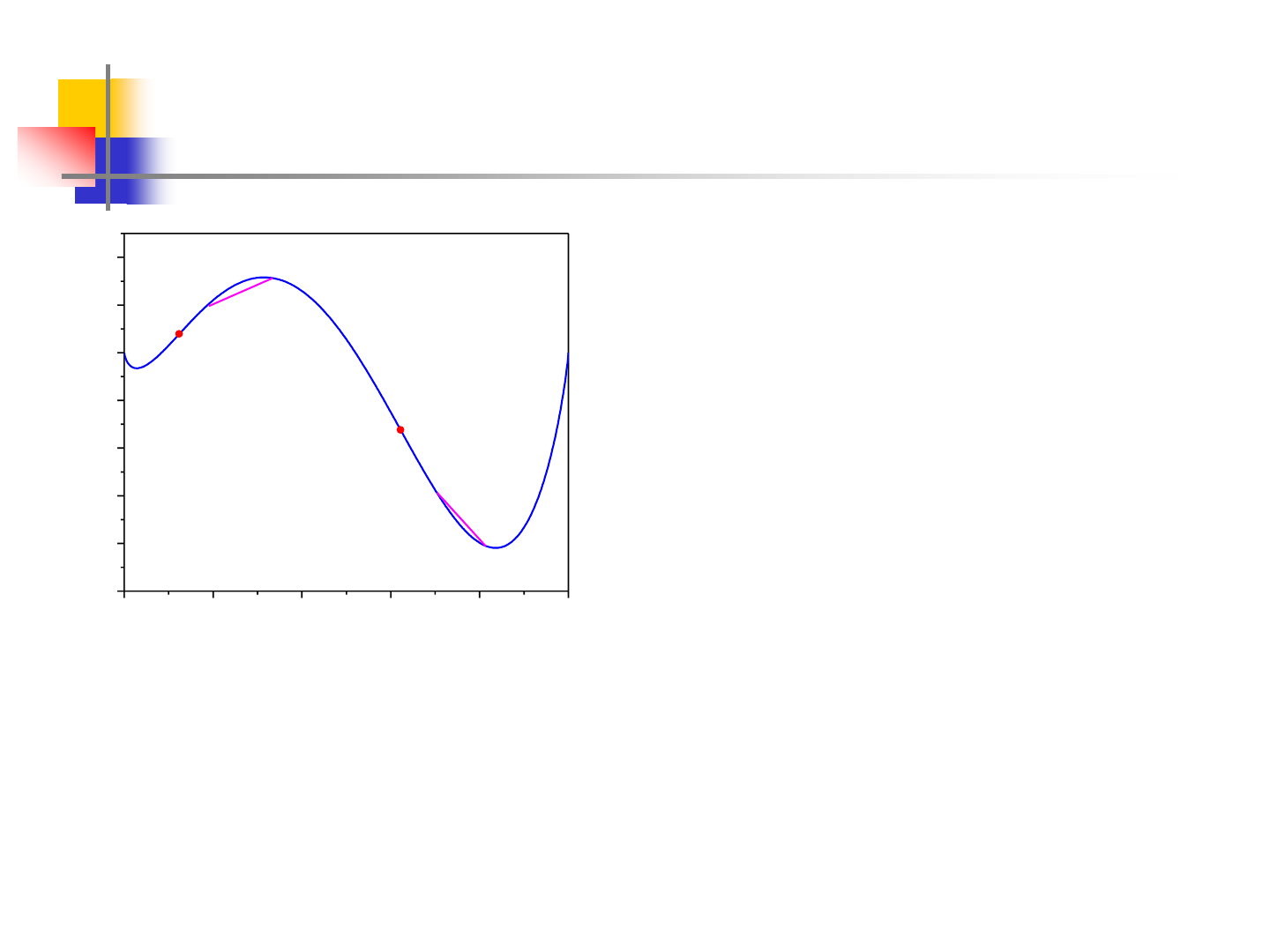

Miscibility Gap – Real Example

0.0 0.2 0.4 0.6 0.8 1.0

300

400

500

600

700

Tc = 622.3K

Xc = 0.344

2

1

Zn

Al

T / K

mol. fracn. Zn

0.0 0.2 0.4 0.6 0.8 1.0

-2.5

-2.0

-1.5

-1.0

-0.5

0.0

0.5

700K

622.3K

500K

400K

300K

ZnAl

mix

G (kJ/mol)

mol. fracn. Zn

holds. 0

dx

Gd

dx

Gd

only solutions,regular -sub-subor regular -sub

for but solution,regular for holds at x 0

dx

Gd

dx

Gd

dx

dG

,TT As

3

3

2

2

c

3

3

2

2

C

==

===→

14

Miscibility Gap – Real Example

0.0 0.2 0.4 0.6 0.8 1.0

-2.5

-2.0

-1.5

-1.0

-0.5

0.0

0.5

T=Tc=622.3K

ZnAl

mix

G (kJ/mol)

mol. fracn. Zn

0.0 0.2 0.4 0.6 0.8 1.0

-20

-10

0

10

20

x

Zn

Zn

Al

dG/dx (kJ/mol)

0.0 0.2 0.4 0.6 0.8 1.0

0

20

40

60

80

100

120

Zn

Al

d

2

G/dx

2

(kJ/mol)

x

Zn

0.0 0.2 0.4 0.6 0.8 1.0

-600

-400

-200

0

200

400

600

Zn

Al

x

Zn

dG

3

/dx

3

(kJ/mol)

15

Chemical Spinodal

0.0 0.2 0.4 0.6 0.8 1.0

-1.0

-0.8

-0.6

-0.4

-0.2

0.0

0.2

0.4

b

a

d

c

S2

S1

T=300K

Zn

Al

mix

G (kJ/mol)

mol. fracn. Zn

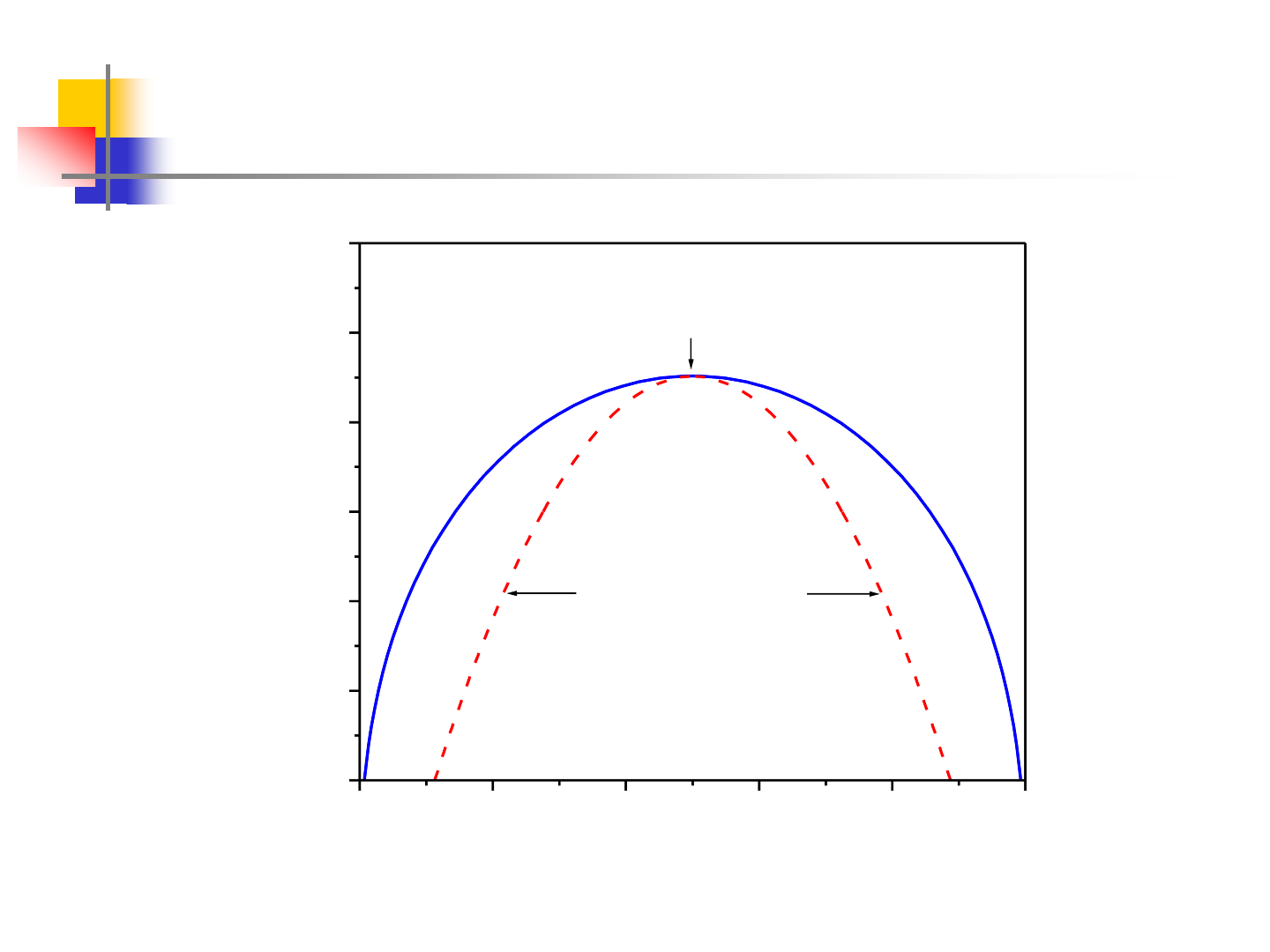

(a) Between the spinodal compositions,

the Gibbs energy of homogenous single-

phase alloy is always higher than that of

any mixture of compositions (c and d,

for example), which can form from a

decomposition of this phase.

(b) Between the miscibility gap and the nearby spinodal composition,

the Gibbs energy will increase if a single-phase alloy decomposed

locally to form any mixture of compositions(a and b, for example).

Decomposition can only take place by nucleation of the other phase.

16

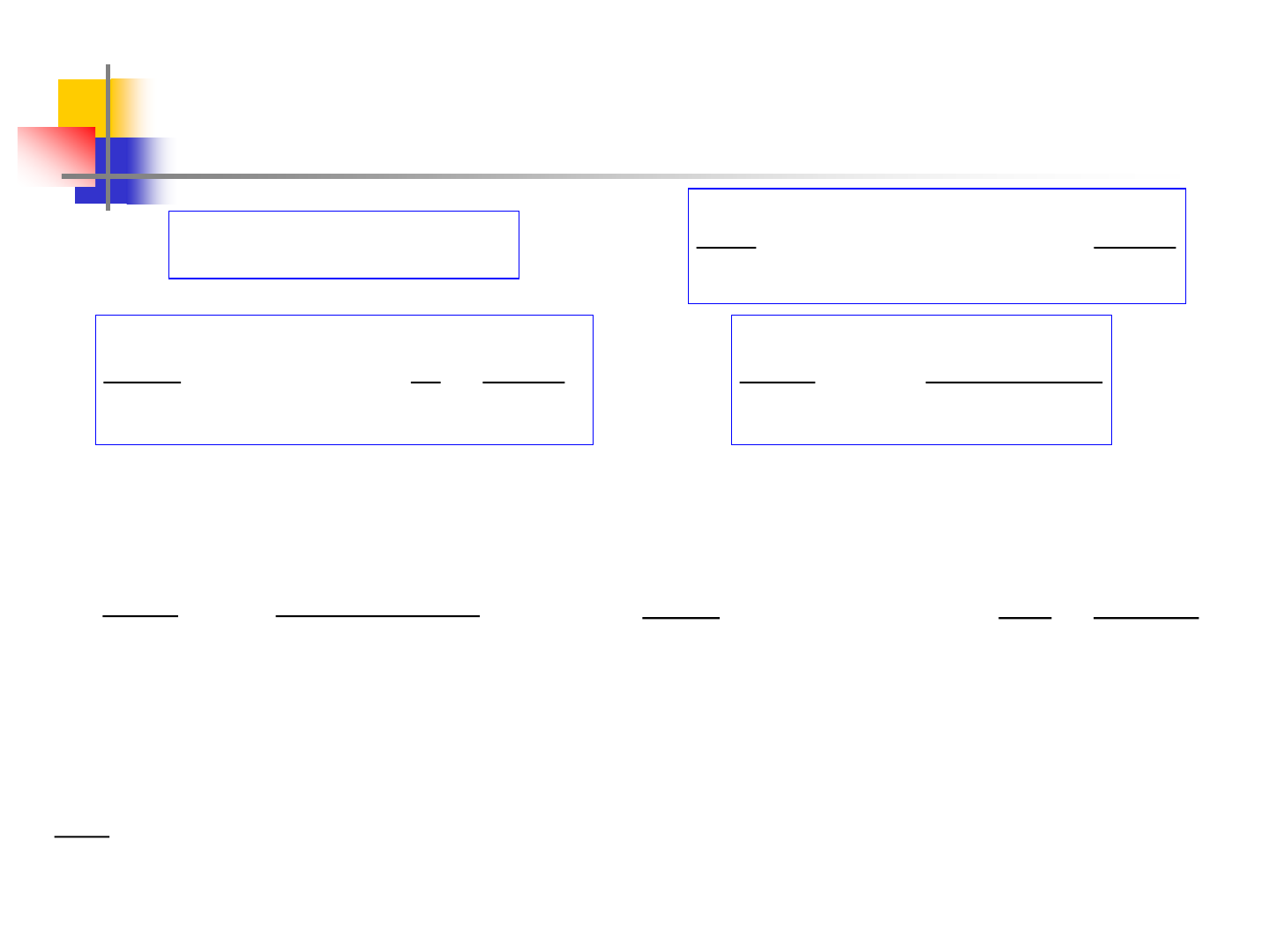

Gibbs’ Phase Rule

The Phase Rule is concerned with evaluating the number of

independent intensive variables (degrees of freedom) required to

specify a state, i.e. the different features of a phase diagram.

I. Total number of variables

Total number of variables for each phase: C+2

Total number of variables for phases: (C+2)

II. Constraints

(a) T

(1)

= T

(2)

= … = T

()

(-1) relations

(b) p

(1)

= p

(2)

= … = p

()

(-1) relations

(c)

I

(j)

constraints R

relations

17

Gibbs’ Phase Rule

III. Number of independent variables, F

F = C + 2 - R

p-V work only

F = C + 1 - R

p-V work only, at constant p

When there are phases and C components: C(-1) constraints

Gibbs-Duhem equation for each phase: constraints

Thus: R

= C(-1) +

F = C - + 2 p-V work only

F = C - + 1 p-V work only, at constant p

18

END !