PanEngine

TM

User’s Guide

CompuTherm, LLC

Copyright

c

2012-2020

Getting Help

CompuTherm LLC is committed to providing you with the best possible technical support. Please contact us

via the following approaches:

Web Site

www.computherm.com

E-Mail

info@computherm.com

Phone

+1 (608) 203 8843

Fax

+1 (608) 203 8045

Mail

CompuTherm LLC

8401 Greenway Blvd., Suite 248

Middleton, WI 53562

USA

Declaration

This document is furnished by CompuTherm LLC for information purposes only to licensed users of

the

PanEngine

product and is furnished on an AS IS basis without any warranties expressed or implied.

Information in this document is subject to change without notice and does not represent a commitment on

the part of CompuTherm LLC.

Contents

1 Introduction to PanEngine 1

1.1 What is PanEngine? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Advantages of PanEngine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 API in PanEngine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 Getting Started with PanEngine 3

2.1 Installation of PanEngine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Getting Started with PanEngine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Basic Concepts 9

3.1 Gibbs Energy Models for Multi-Component Phases . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1.1 Stoichiometric compound . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1.2 Disordered solution phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1.3 Ordered intermetallic phase using the compound energy formalism . . . . . . . . . . . 10

3.2 PanEngine Classes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2.1 class P Component . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2.2 class P Species . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2.3 class P Statespace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2.4 class P Phase Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2.5 class P Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 PanEngine API 13

4.1 Functions for PanEngine Pointer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1.1 Define a PanEngine pointer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1.2 Delete a PanEngine pointer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2 Functions for System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2.1 Set system configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2.2 Import a thermodynamic database . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2.3 Export a subsystem database into a file (tdb) . . . . . . . . . . . . . . . . . . . . . . . 16

4.2.4 Get component names in a database . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2.5 Deactivate a component in a database . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2.6 Get phase names in a database . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2.7 Get and set phase statuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.3 Functions for Point Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.3.1 Set calculation condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.3.2 Calculate a global phase equilibrium . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.3.3 Calculate a global phase equilibrium with initials . . . . . . . . . . . . . . . . . . . . . 18

4.3.4 Calculate a local phase equilibrium . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.3.5 Find the liquidus surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.3.6 Find the liquidus slopes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.4 Function for Solidification Simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.5 Thermodynamic Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.6 Hessian matrix of Gibbs energy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.7 Parallel Tangent Equilibrium . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5 Examples 24

5.1 Test Example 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.2 Test Example 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.3 Test Example 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.4 Test Example 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.5 Test Example 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.6 Test Example 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.7 Test Example 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.8 Test Example 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.9 Test Example 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1 INTRODUCTION TO PANENGINE 1

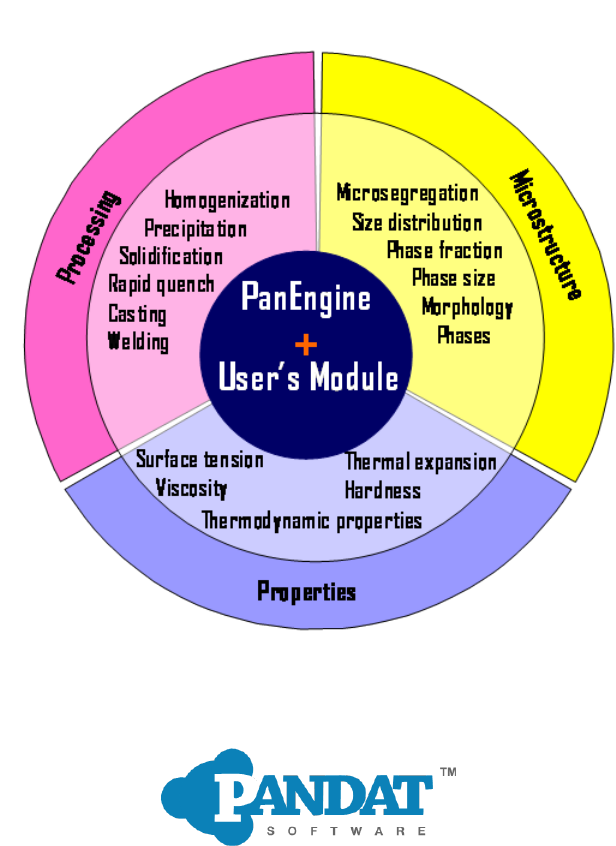

1 Introduction to PanEngine

1.1 What is PanEngine?

PanEngine

is a dynamically linked library (DLL) for multi-component thermodynamics and phase equilibrium

calculations.

PanEngine

is the calculation engine of Pandat. It has an application program interface (API)

which allows a users custom programs to access the functions in

PanEngine

. It is implemented with C++TR1

standard in Microsoft Visual Studio. The examples in this manual were prepared under Microsoft Visual

Studio 2013 and 2015.

A library is a group of functions, classes, or other resources that can be made available to application

programs that need previously implemented entities without the need to know how these functions, classes,

or resources were created or how they function. A dynamic link library is a program that holds one or more

functions or some functionality that other programs can use. Through

PanEngine

s API, users can call the

thermodynamic functions available in PanEngine and create custom software for their specific applications.

Custom Software Applications

PanEngine can be used by users to create custom software applications such as:

• Microscopic solidification simulations

– Microstructure: e.g. the secondary dendrite arm spacing

– Microsegregation: e.g. the concentration profile within a dendrite arm

• Macroscopic solidification simulations

–

Casting simulations:

PanEngine

provides enthalpy and the fraction-solid as a function of tempera-

ture

• Heat treatment simulations

•

Other applications where phase equilibrium information and thermodynamic properties are needed,

such as the cellular automaton (CA) and phase field simulations

1.2 Advantages of PanEngine

PanEngine

automatically finds the correct, stable phase equilibria without requiring the user to guess initial

values. This is especially important when integrating with users custom program for the following reasons:

•

It is very difficult for the user to provide initial values and verify results when a custom software

program needs stable phase equilibrium repeatedly for thousands of points.

•

It is almost impossible for users to guess the initial values in a multi-component phase equilibrium

calculation.

1.3 API in PanEngine

PanEngine

’s API has many commonly used functions. Some of them are listed below and more details will

be given in the following sections.

• Import databases

1 INTRODUCTION TO PANENGINE 2

• Set calculation conditions

• Calculate stable equilibria

• Calculate metastable (local) equilibria

• Calculate parallel tangent equilibria for phase field modeling

• Calculate driving force of phase

• Find liquidus surface

• Calculate liquidus slope

• Calculate partitioning coefficients

• Simulate solidification process using Scheil or lever rule model

• Calculate physical properties such as molar volume and density

• Calculate kinetic properties such as mobility and diffusivity

• Calculate Hessian matrix of Gibbs free energy and its eigenvalues and eigenvectors

2 GETTING STARTED WITH PANENGINE 3

2 Getting Started with PanEngine

2.1 Installation of PanEngine

PanEngine

is available only from CompuTherm LLC. Once purchased, a hardware dongle will be provided

with

PanEngine

.

PanEngine

will not run if the dongle is not attached to the users computers USB port.

PanEngine

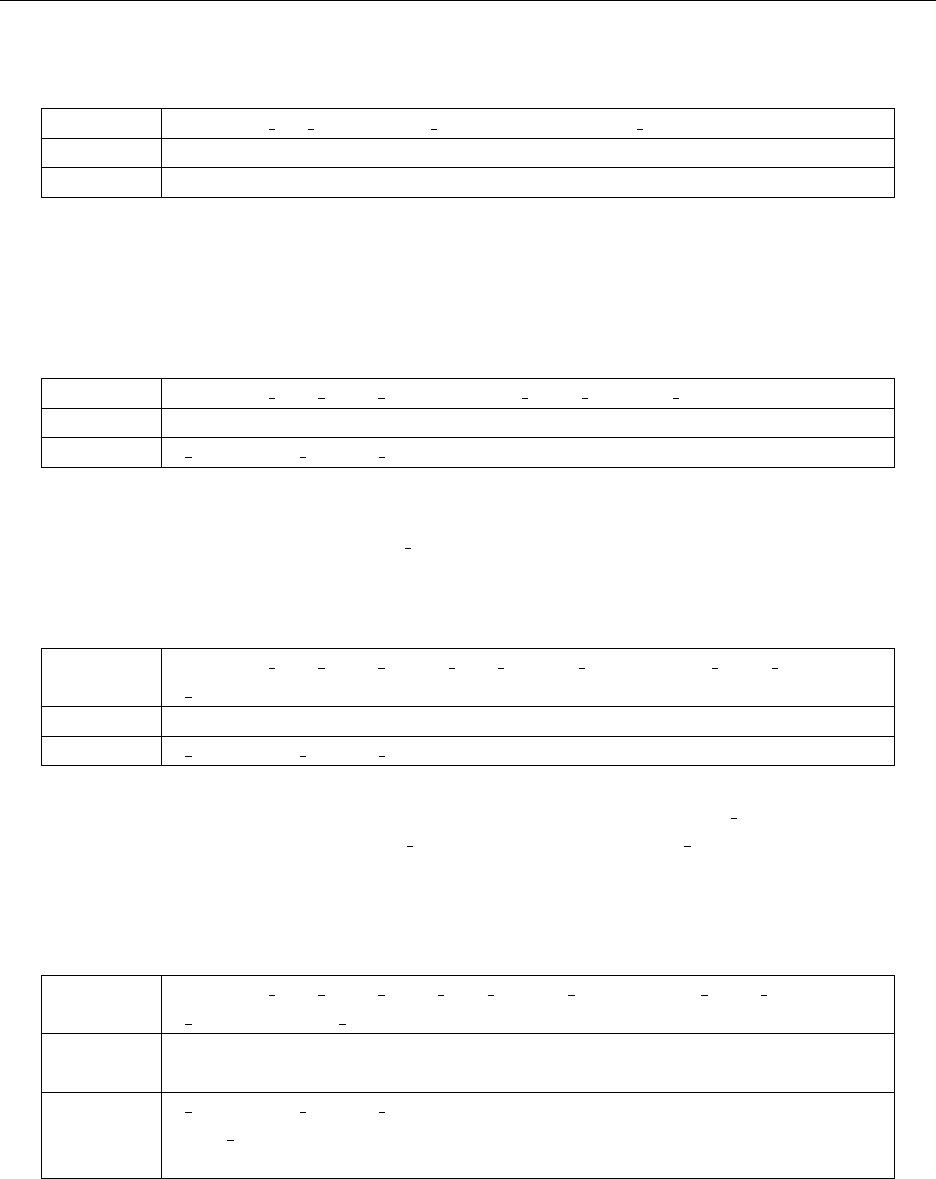

consists of several different types of files. As shown in Table 1, the

PanEngine

thermodynamic

calculation interface includes four

DLL

files, one library file, six header files, Visual Studio Solution and

Project files, and some test example files.

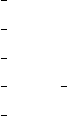

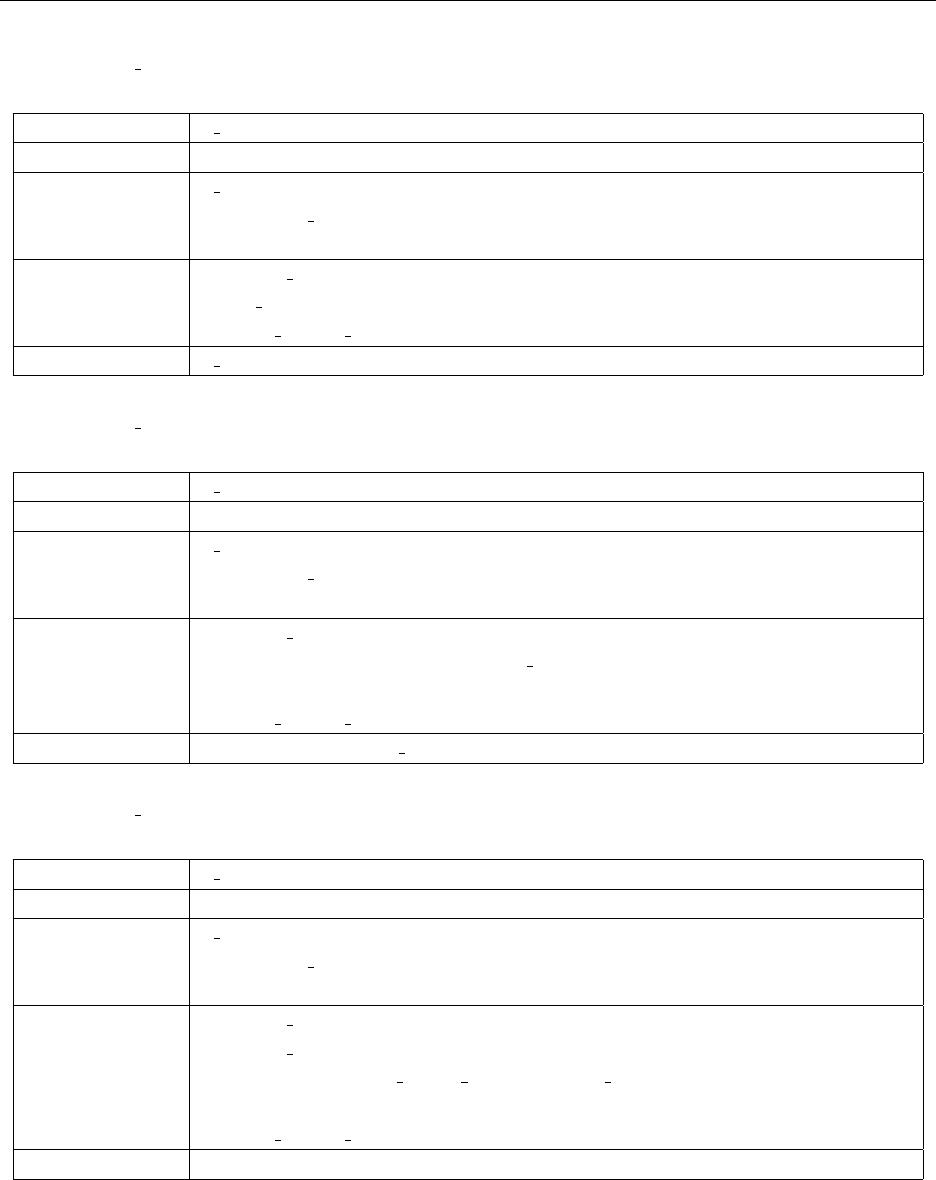

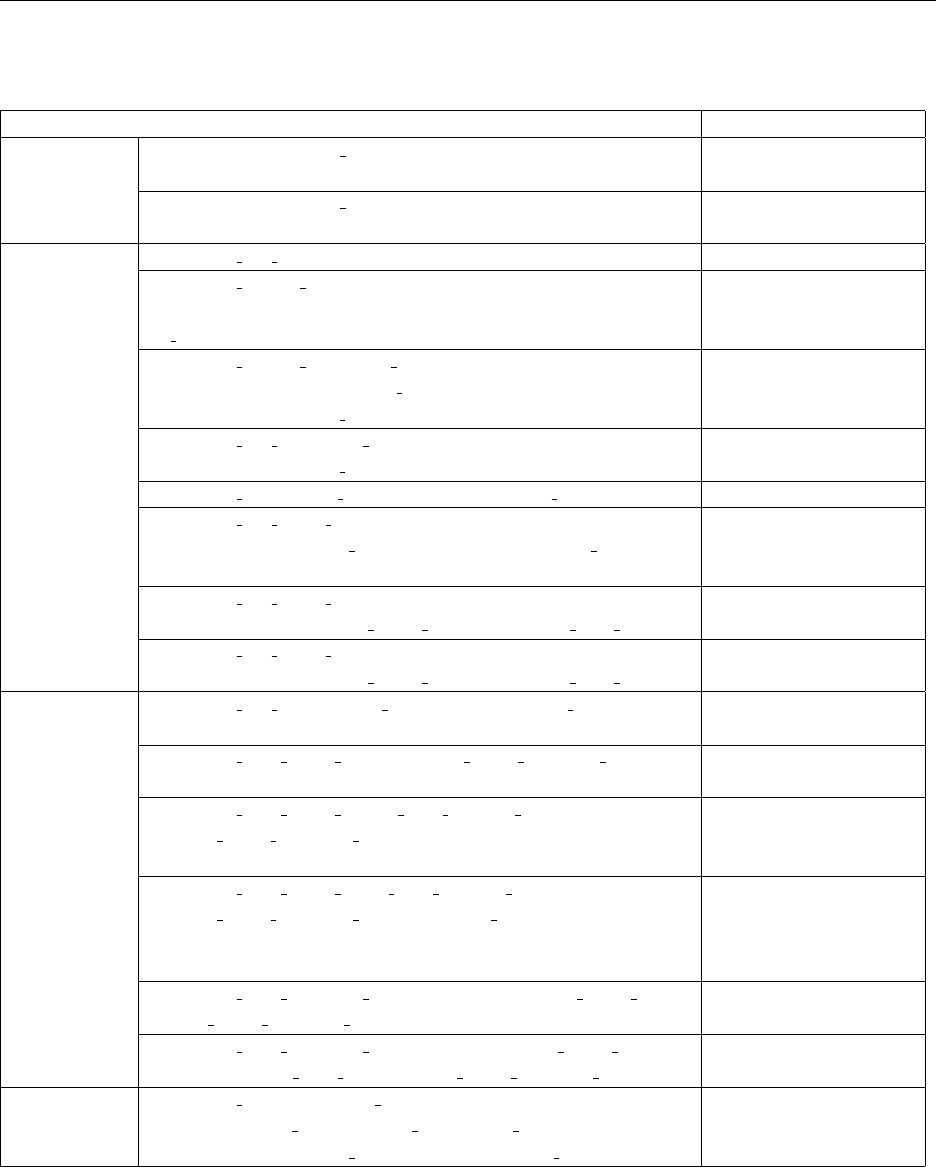

Table 1: List of PanEngine Files

File Name Comment

PanEngineX.dll PanEngine dynamically linked library

PanSolverX.dll

haspms32.dll

hasp windows 57714.dll

Collection of dynamically linked libraries used by PanEngineX.dll

PanEngineX.lib PanEngine library file

PanEngineX.h PanEngine header file

std.h Standard header file

stl.h Standard Template Library (STL) header file

Pan Global.h

Pan Global Def.h

solidification.h

Other header files

main.cpp Main program

PanEngineTest *.cpp PanEngine test example files (*=1,2,· · · ,9)

AlMgZn.tdb, AlSiZn.tdb,

FeNiCr.tdb,

NiAlNb Pseudo.tdb

Example database files in tdb format

PanEngineXTest.sln Visual Studio Solution file

PanEngineXTest.vcxproj VC++ Project file

PanEngineXTest.exe or

PanEngineXTest demo.exe

Compiled executable application file

The installation of

PanEngine

is rather straightforward. Simply copy all the files in the

PanEngine

2 GETTING STARTED WITH PANENGINE 4

distribution CD or unzip the compressed files to any working directory where the user intends to place

his/her own codes for applications. The library files can also locate in any other area, and can be accessed

by specifying their appropriate paths in the application program codes. The current

PanEngine

can run on

most of current versions of Windows.

The recommended programming environment with

PanEngine

is Microsoft Visual Studio 2013 or 2015.

Visual Studio 2013 or 2015 is the programming environment in which

PanEngine

was created. If a user uses

a different C++ compiler, the

PanEngine

Visual Studio Solution file and corresponding project file may not

work and then a completely new Solution and project files or make file need to be constructed by the user.

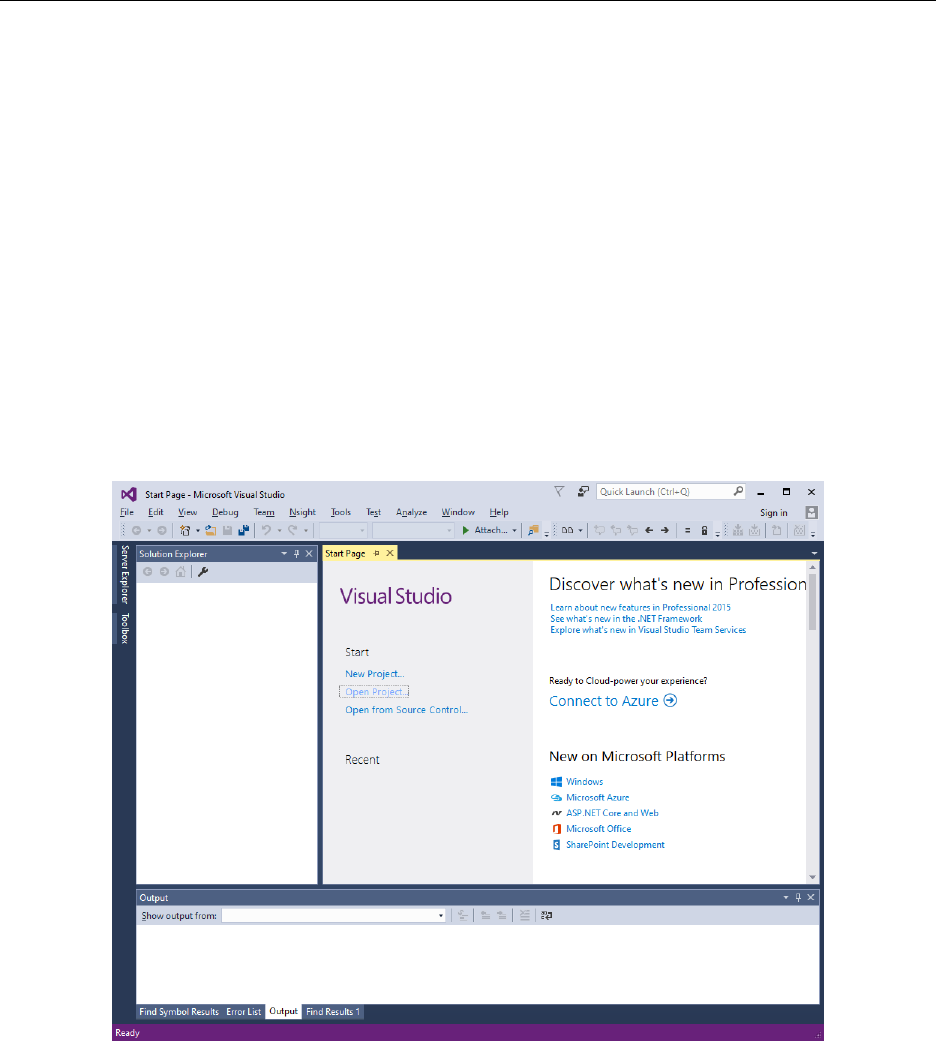

2.2 Getting Started with PanEngine

We assume that a full version of Microsoft Visual Studio 2013 or 2015 is installed on the user’s computer.

Follow the steps below to run the PanEngine test examples.

1. Attach the CompuTherm hardware dongle to the computer.

2. Start Microsoft Visual Studio 2013 or 2015.

2 GETTING STARTED WITH PANENGINE 5

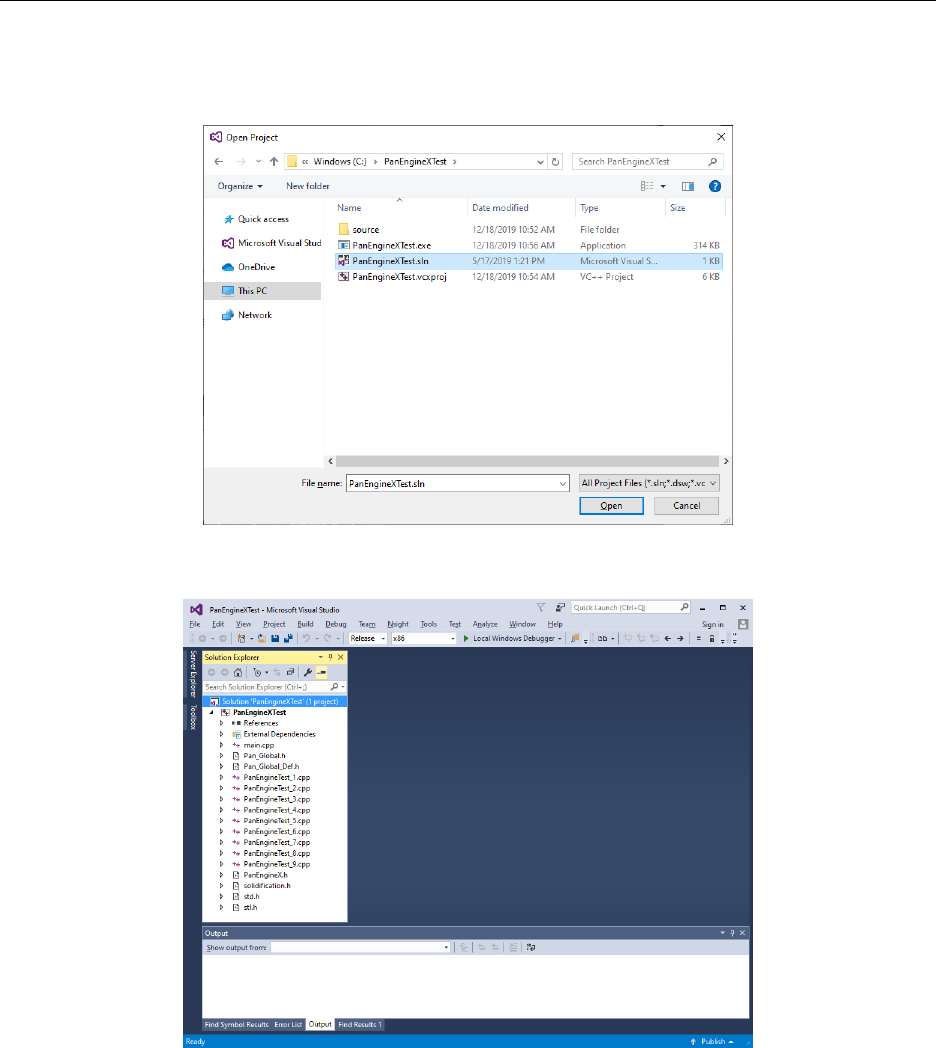

3. On the

Start

page of Visual Studio 2013 or 2015, click on

Open Project

. Go to the folder

/PanEngineXTest (in the user’s hard drive) and open PanEngine.sln.

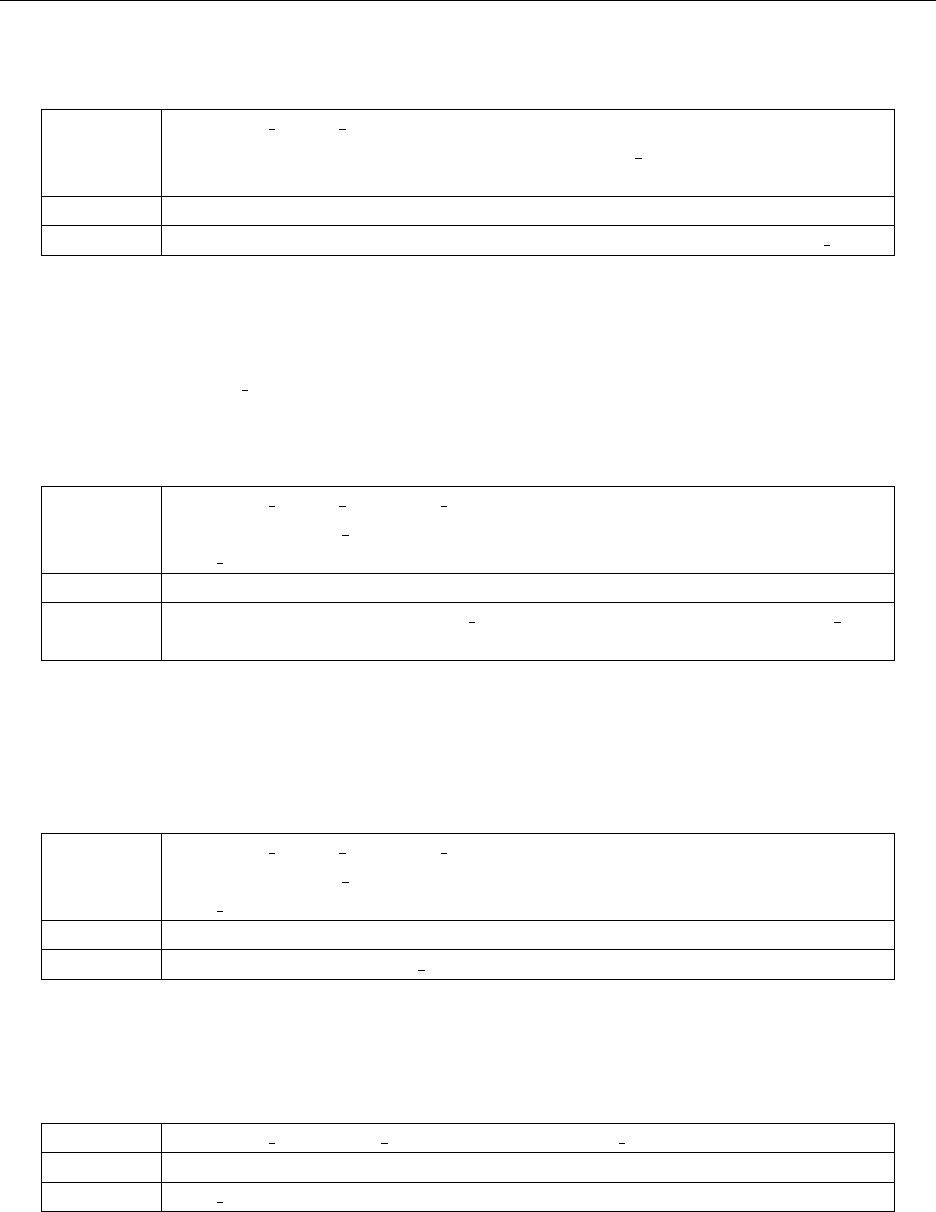

Here is what we will see in Visual Studio after expanding the file folders in the Solution Explorer:

2 GETTING STARTED WITH PANENGINE 6

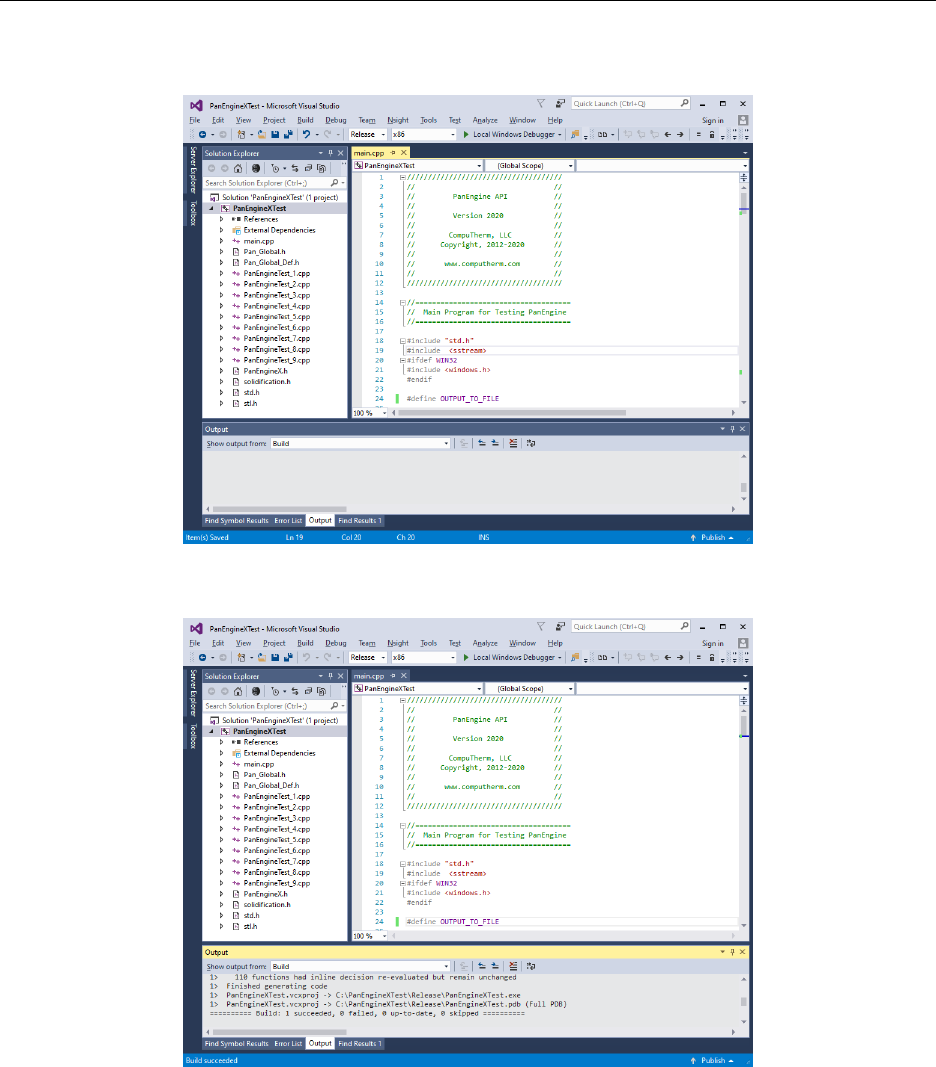

4. Double click on the file main.cpp in the Solution Explorer window.

5. Rebuild PanEngine by clicking Build → Rebuild Solution.

2 GETTING STARTED WITH PANENGINE 7

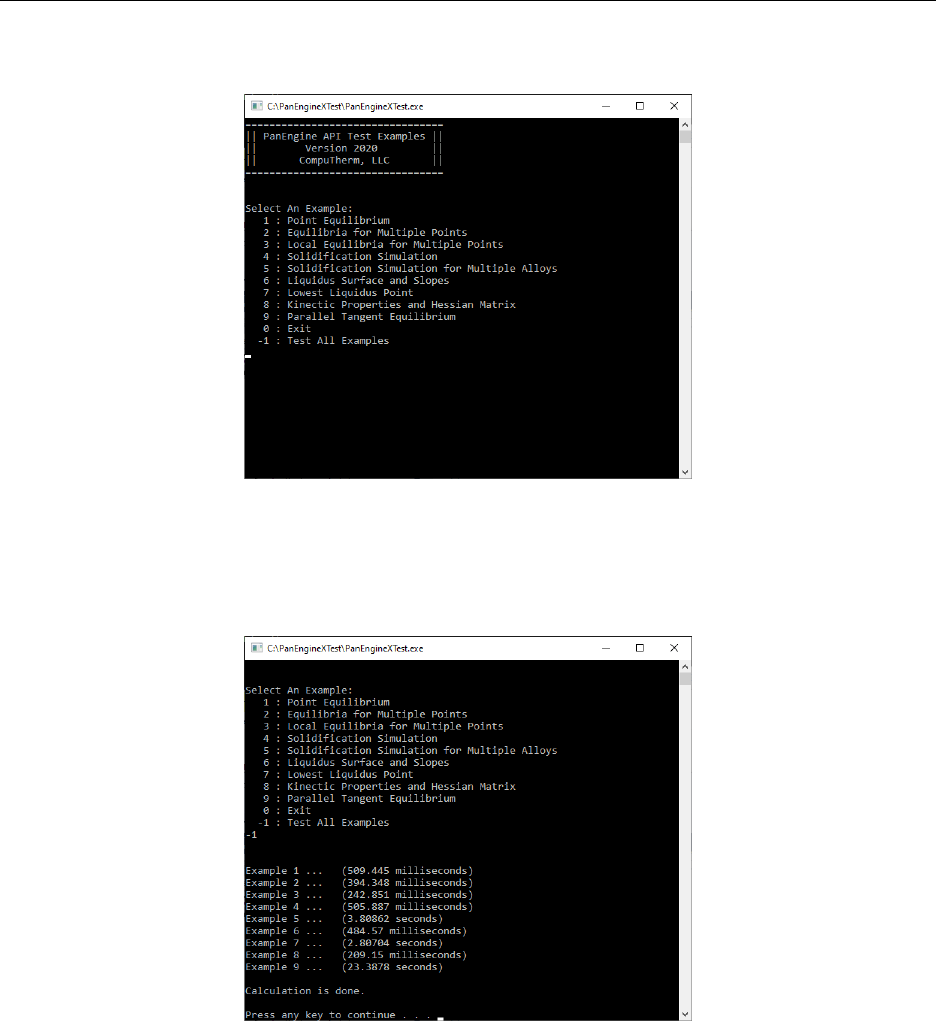

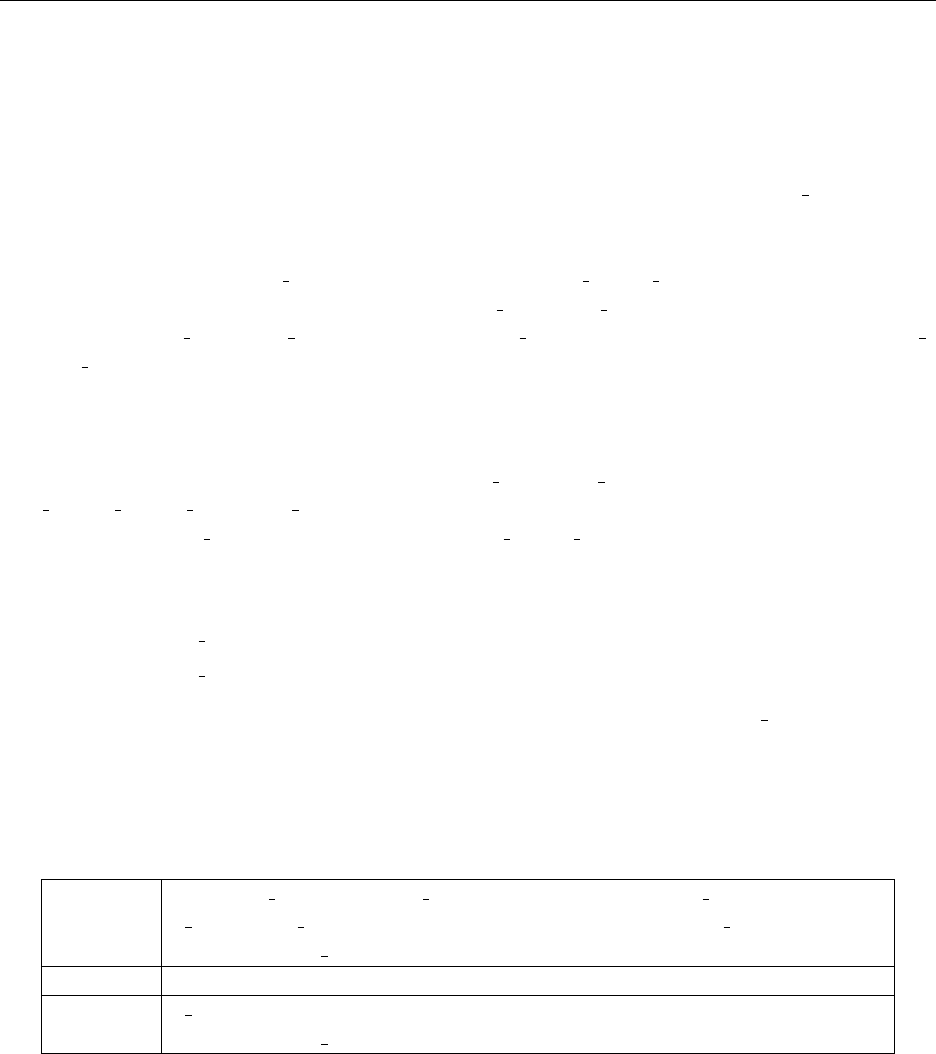

6. Press F5 to run the test examples. A Command window will pop up as below.

There are nine test examples to select. To select a test example, enter the example ID

1

to

9

. Type “

0

”

to exit, and type “

-1

” to run all the test examples together. The

Command

window will show the intermediate

results of the calculations. The final status of the window looks like the following one, except that the path

name on the top of the window will depend on the location of PanEngine on the user’s computer.

7. Press any key and return to the Visual Studio 2013 or 2015 main window.

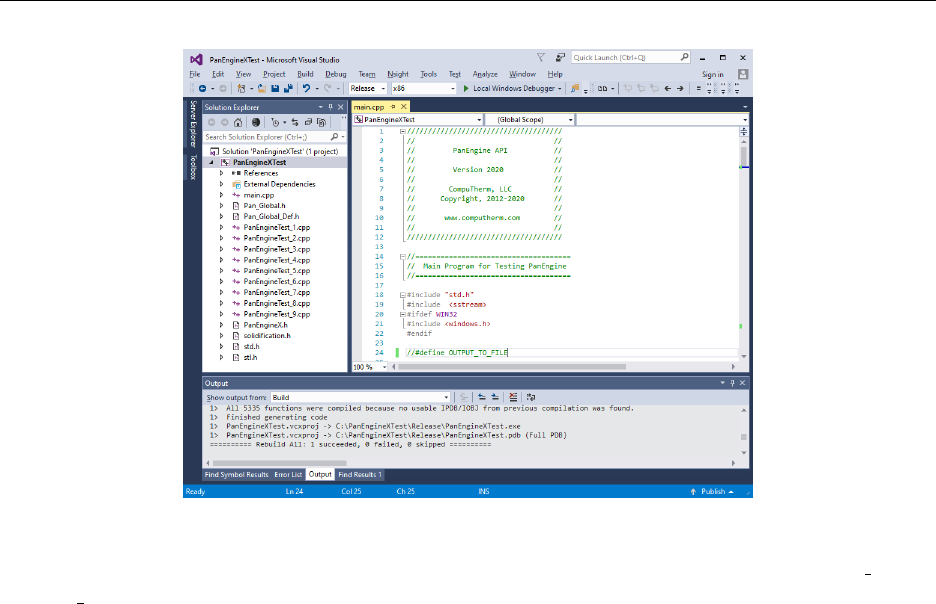

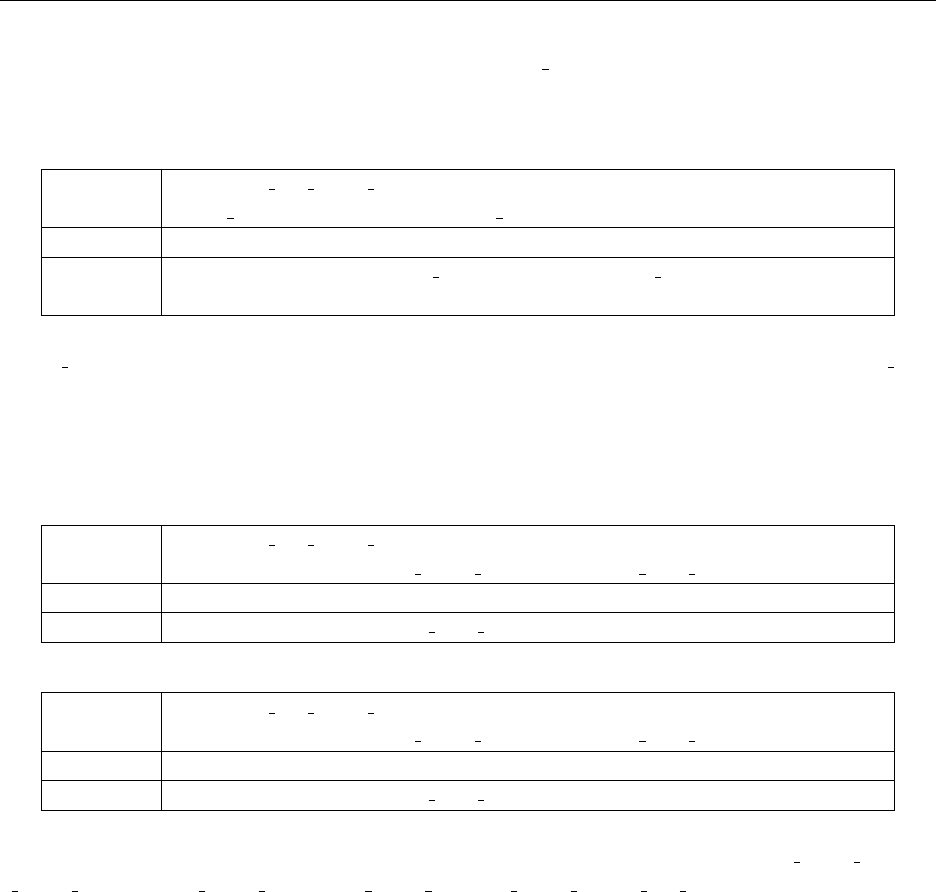

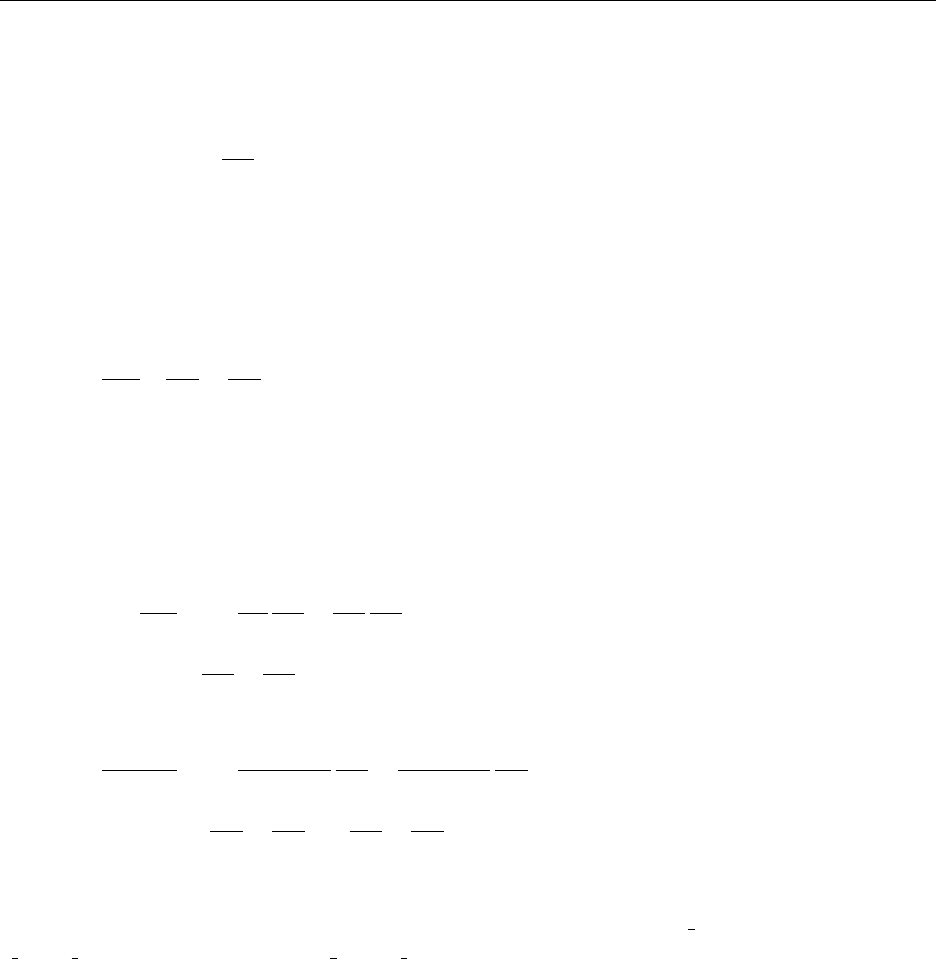

In the main.cpp, there is a line

#define OUTPUT_TO_FILE

as shown in the following image.

2 GETTING STARTED WITH PANENGINE 8

If this

#define

line is commented out, as in above image, the intermediate calculation results will be

shown in the

Command

window. Otherwise, the results will be output into a file with a name of “

test 1.dat

”,

or “test 2.dat”, etc.

In the following, we will introduce some basic concepts used in

PanEngine

and describe the details of the

API and the test examples.

3 BASIC CONCEPTS 9

3 Basic Concepts

In the CALPHAD approach, the Gibbs energies of all the phases in an alloy system are described by

thermodynamic models, such as the ones for stoichiometric phases, the regular-solution-type model for

disordered phases, and the sublattice model for ordered phases with a range of homogeneity or an order/disorder

transition. These types of models have been implemented in PanEngine.

PanEngine

was developed with C++ language. It consists of many C++ classes. The

P Point

C++

class refers to a system with a specified composition at a certain temperature and pressure. A

P Point

object is directly interfaced with the users code. The user can change the conditions (temperature or overall

compositions) of the system through a

P Point

object and get back the thermodynamic properties and phase

equilibrium information under the newly specified conditions. The stable (or metastable) phase equilibrium

information of the system (such as phase fractions, composition of each phase, and thermodynamic properties

for each phase) are described by

P Phase Point

Class. General information about the system, such as alloying

components, alloy overall composition and temperature, are stored in

P Statespace

class. The details on

these and other classes can be found in the C++ header files of Pan Global Def.h and Pan Global.h.

In the following, we will first give a brief introduction of thermodynamic models and then describe the

different classes used in PanEngine.

3.1 Gibbs Energy Models for Multi-Component Phases

3.1.1 Stoichiometric compound

The Gibbs energy of a stoichiometric phase is expressed as

G =

n

X

i=1

x

i

G

◦,φ

i

+ G

f

(1)

where

x

i

is the mole fraction of component

i

,

G

◦,φ

i

is the Gibbs energy of the pure component

i

with structure

φ

, and

G

f

is the Gibbs energy of formation of the stoichiometric phase referred to the structure

φ

for each

component i.

3.1.2 Disordered solution phase

The Gibbs energy of a disordered solution phase is expressed as

G =

n

X

i=1

x

i

G

◦,φ

i

+ RT

n

X

i=1

x

i

ln x

i

+ G

ex,φ

(2)

where

x

i

is the mole fraction of component

i

,

G

◦,φ

i

is the Gibbs energy of the pure component

i

with structure

φ

,

R

is the gas constant, and

T

is the absolute temperature.

G

ex,φ

is the excess Gibbs energy of the phase,

defined as

G

ex,φ

=

n−1

X

i=1

n

X

j=i+1

x

i

x

j

m

X

l=0

L

(l)

ij

(x

i

− x

j

)

l

+

n−2

X

i=1

n−1

X

j=i+1

n

X

k=j+1

x

i

x

j

x

k

X

l=i,j,k

L

(l)

ijk

V

(l)

ijk

(3)

3 BASIC CONCEPTS 10

where the first term represents the binary interaction terms, the second represents ternary interactions. The

L

(l)

ij

’s are binary interaction parameters for the

i

-

j

binary and the

L

(l)

ijk

’s are ternary interaction parameters.

V

(l)

ijk

is defined as

V

(l)

ijk

= x

l

+

1 − x

i

− x

j

− x

k

n

(l = i, j, k) (4)

For a ternary system,

V

(l)

ijk

= x

l

(l = i, j, k) (5)

since x

i

+ x

j

+ x

k

= 1.

3.1.3 Ordered intermetallic phase using the compound energy formalism

The Gibbs energy of an ordered intermetallic phase is described as

G = G

ref

+ G

id

+ G

ex

(6)

where

G

ref

is expressed in terms of compound energies (which are constant at constant temperature) and

their associated sublattice species concentrations, y

i

p

,

G

ref

=

X

y

i

p

y

j

q

· · · y

l

s

G

p:q:···:s

(7)

G

id

is the ideal mixing term, which assumes the random mixing of species on each sublattice,

G

id

=

l

X

i=1

f

i

m

X

p=1

y

i

p

ln y

i

p

(8)

G

ex

is also expressed as a function of species concentrations with the sublattice

L

parameters being the

numerical coefficients in the contributing terms,

G

ex

=

X

y

i

p

y

i

q

y

j

r

L

p,q:r

(9)

where

L

p,q:r

=

X

v

L

v

p,q:r

(y

i

p

− y

i

q

)

v

(10)

3.2 PanEngine Classes

PanEngine

is a dynamically linked library of thermodynamic and phase equilibrium calculation functions.

Most of the communications between the users application code and

PanEngine

are through the objects

of

PanEngine

classes as mentioned at the beginning of this chapter. The headers of

PanEngine

classes are

included in the files

Pan Global.h

and

Pan Global def.h

. The major

PanEngine

classes with frequently

used functions and properties are described below. Please refer to the header files of

Pan Global.h

and

Pan Global def.h. for other classes.

3 BASIC CONCEPTS 11

3.2.1 class P Component

Class Name P Component

Definition a component is made up of one or more elements, for example: Al or FeO

Public Functions

P Component()

virtual ~P Component()

(and other copy constructors and operators)

Public Properties

string m name // component name

int m id // component ID

(see Pan Global Def.h for other member variables)

Comments P Component holds information for a component

3.2.2 class P Species

Class Name P Species

Definition species can be made up of one or more components, for example: O2

Public Functions

P Species()

virtual ~P Species()

(and other copy constructors and operators)

Public Properties

string m name // species name

vector<pair<string, double>>m c

// first:component name; second:amount of component

(see Pan Global Def.h for other member variables)

Comments associate model uses P Species to define the species of the associates

3.2.3 class P Statespace

Class Name P Statespace

Definition

Statespace describes temperature, pressure and composition of a system or a phase

Public Functions

P Statespace()

virtual ~P Statespace()

(and other copy constructors and operators)

Public Properties

double m T; // in K, system temperature

double m P; // in pascal, system pressure

map<string, shared ptr<P Component>>m comp

// collection of components

(see Pan Global Def.h for other member variables)

Comments most of calculation conditions are set through this class

3 BASIC CONCEPTS 12

3.2.4 class P Phase Point

Class Name P Phase Point

Definition

information for a phase after a calculation: the state space, thermodynamic

properties, species concentrations, etc.

Public Functions

P Phase Point()

virtual ~P Phase Point()

(and other copy constructors)

Public Properties

string m phase name // phase name

int m phase id // phase ID

(see Pan

Global Def.h for other member variables)

Comments the objects of this class will be created by PanEngine after calculation

3.2.5 class P Point

Class Name P Point

Definition an equilibrium state with one or more phase points (P Phase Point)

Public Functions

P Point()

virtual ~P Point()

P Point(const P Point&)

(and other copy constructors and member functions)

Public Properties

shared ptr<P Statespace> m st // statespace for a P Point

vector <shared ptr<P Phase Point>>m ppt;

// phase point in this Point

(see Pan Global Def.h for other member variables)

Comments for solidification, a P Point includes the fractions of solid and liquid

4 PANENGINE API 13

4 PanEngine API

The functions of the

PanEngine

application program interface (API) are defined as virtual functions in a class

of

PanEngine

in

PanEngine.h

, except for the two global functions used for defining a

PanEngine

pointer and

deleting an existing

PanEngine

pointer. These functions can be divided into four categories according to

their purposes:

• PanEngine Pointer

– define a PanEngine pointer and initialize it

– delete an existing PanEngine pointer

• System

– set system configuration

– import a thermodynamic database

– save a subsystem database

– get system component names

– get system phase names

– get active phase names

– set phase status

– get phase status

– activate a phase

– deactivate a component

– set calculation condition

• Point Calculation

– find globally stable equilibrium

– find globally stable equilibrium with initial

– find metastable (local) equilibrium with initial

– find liquidus surface

– calculate liquidus slopes

• Solidification Simulation

– lever rule model

– Scheil model

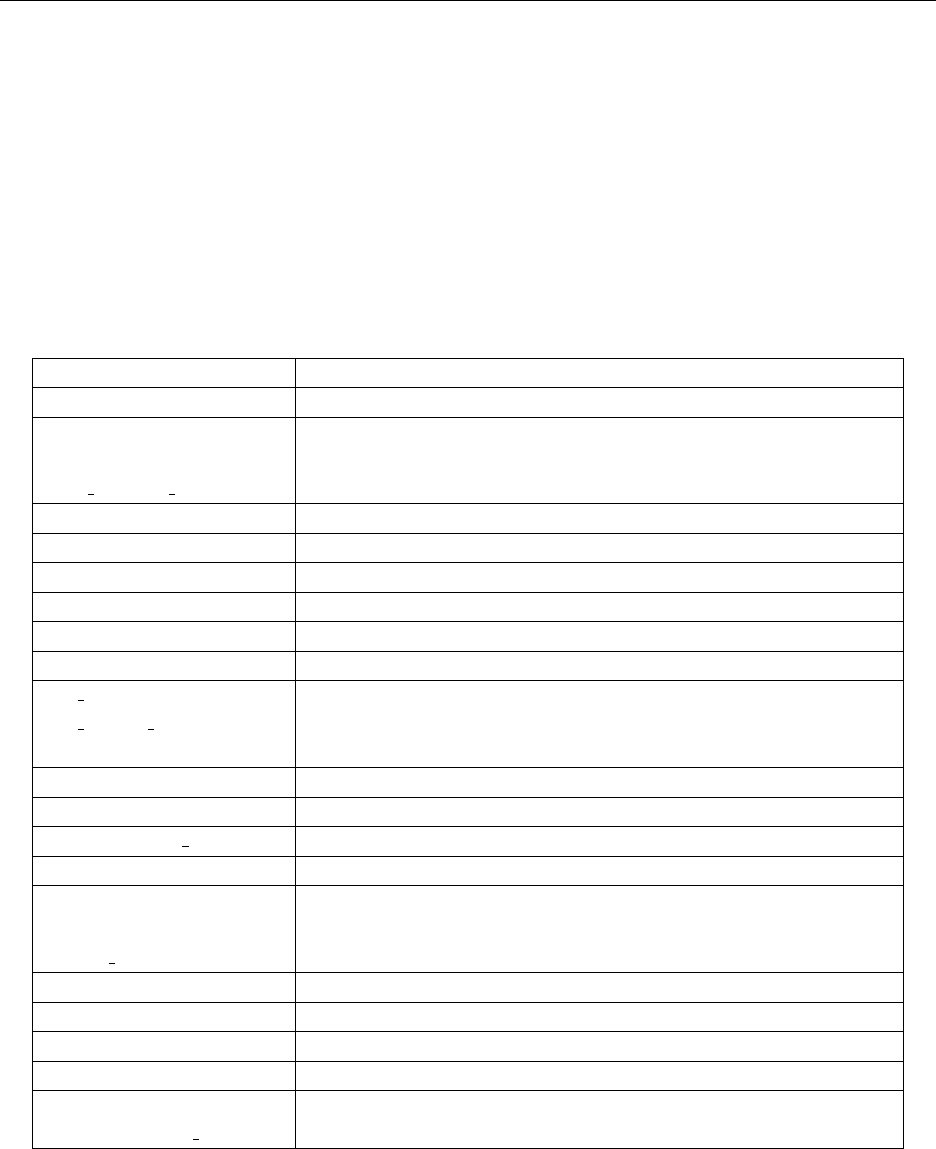

Table 2 summarizes the functions of

PanEngine

API. These functions will be explained in detail in the

following sections.

4 PANENGINE API 14

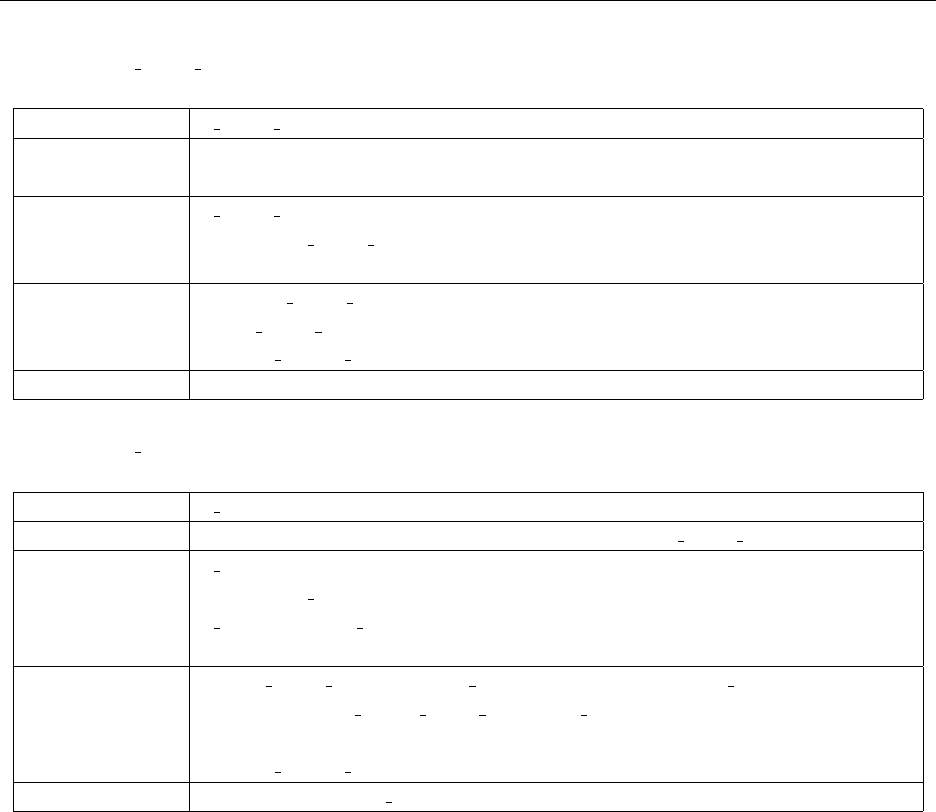

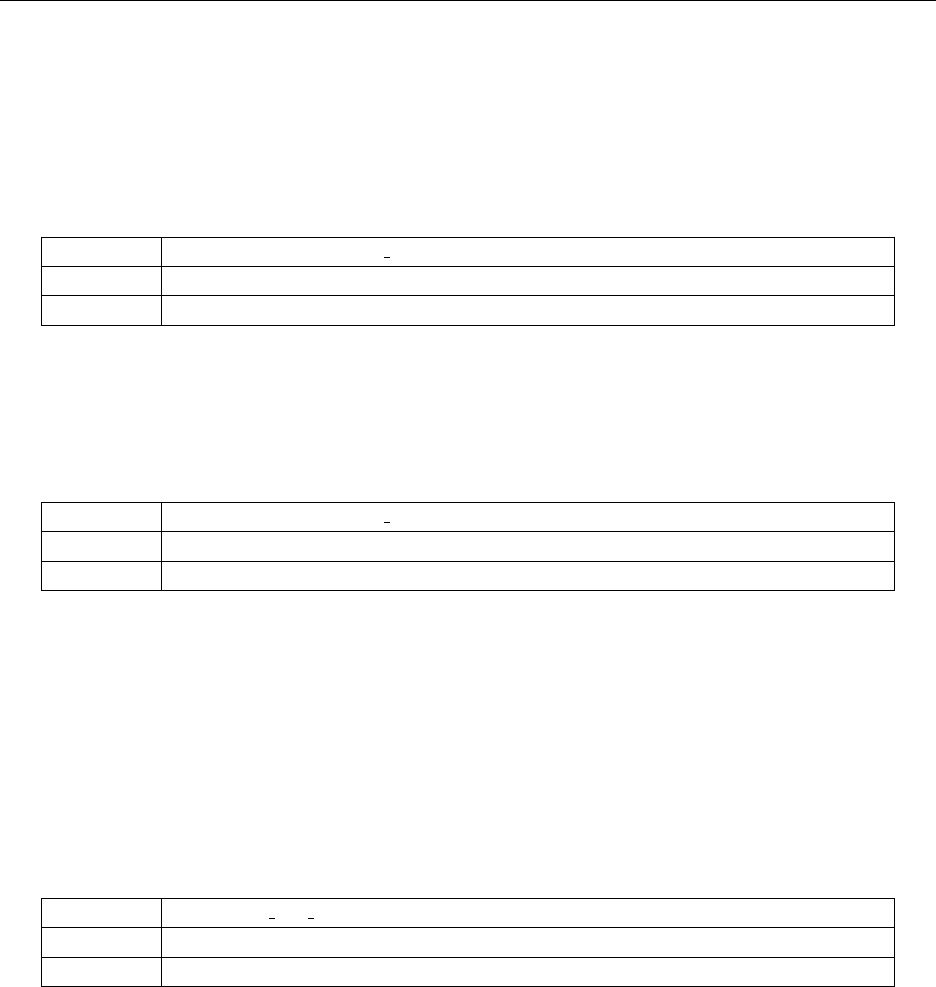

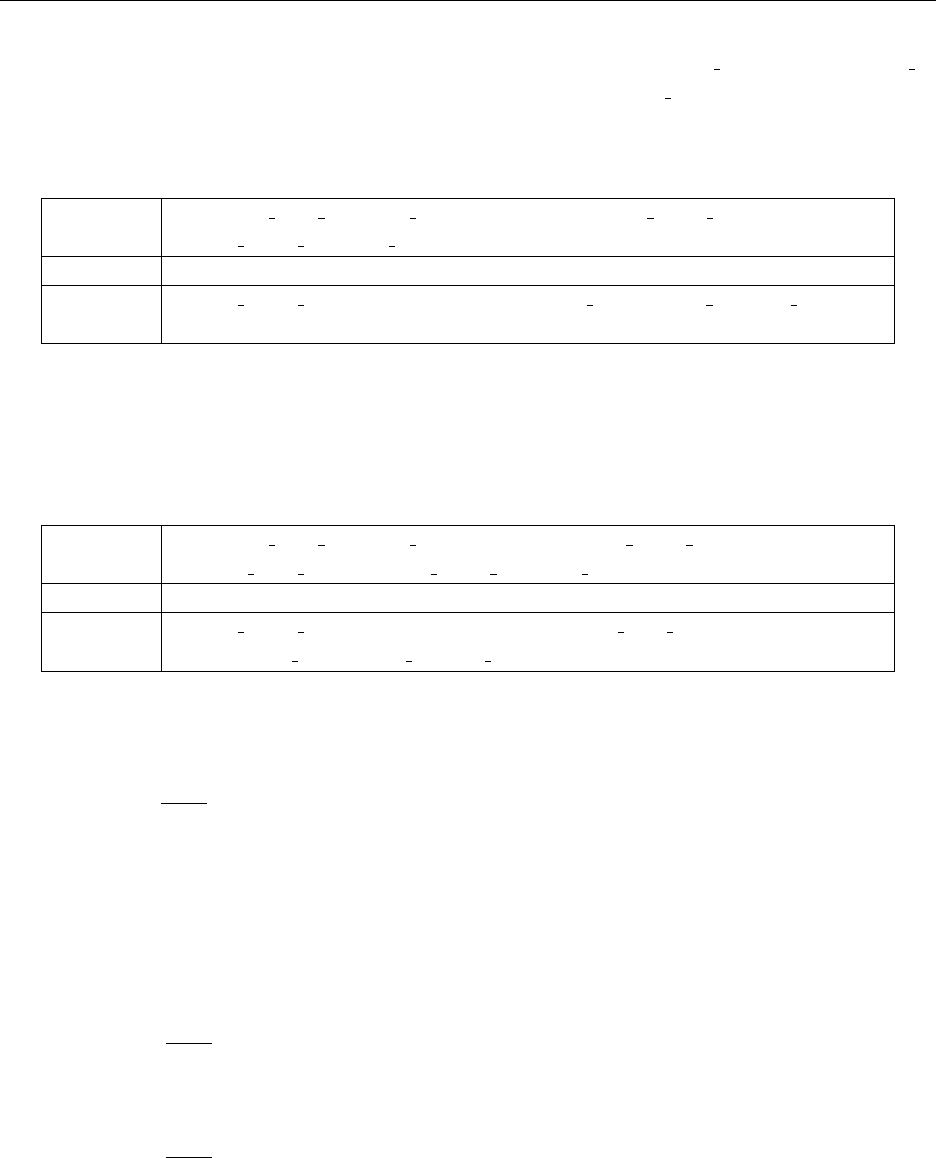

Table 2: List of PanEngine API Functions

Functions Comments

User Pointer

extern "C" PANENGINE API PanEngine*

definePanEngineUser(char* msg)

define a PanEngine

pointer

extern "C" PANENGINE API void

deletePanEngineUser(PanEngine *pUser)

delete a PanEngine

pointer

System

string pe set configuration(map<string, string>& config) set system configuration

string pe import database(pair<string, string>&

db, bool append=false, const pair<string, string>&

db to=pair<string, string>())

import thermodynamic

database

string pe export subsystem database(pair<string, string>&

db, const string subsystem name=string("sub.tdb"), const

vector<string>& comp name = vector<string>())

save a subsystem

database

string pe get component names(pair<string, string>& db,

vector<string>& comp name)

get component names in

a database

string pe deactivate component(string& comp name) suspend a component

string pe get phase names(pair<string, string>& db,

vector<string>& phase name, vector<string> comp name =

vector<string>())

get phase names in a

database with a given

set of components

string pe get phase status(pair<string, string>& db,

vector<pair<string, PAN PHASE STATUS>>& phase name status)

get phase status in a

database

string pe set phase status(pair<string, string>& db,

vector<pair<string, PAN PHASE STATUS>>& phase name status)

set phase status in a

database

Point

Calculation

string pe set calculation condition(const Pan Calculation&

calc)

set a calculation

condition

string pe calc point global(shared ptr<P Point> p pt) calculate a global phase

equilibrium for a point

string pe calc point global with initial point

(shared ptr<P Point> p pt)

calculate a global phase

equilibrium for a point

with initials

string pe calc point local with initial point

(shared ptr<P Point> p pt, bool given f=false)

calculate a local phase

equilibrium or parallel

tangent equilibrium for a

point with initials

string pe find liquidus surface(string& liquid phase name,

shared ptr<P Point> p pt)

find a liquidus surface

string pe calc liquidus slope(string& liquid phase name,

string& solvent comp name, shared ptr<P Point> p pt)

calculate liquidus slopes

Solidification

Simulation

String pe solidification simulation

(Solidification Parameter& s param, Pan Calculation& calc,

vector<Solidification Node>& solidification result)

simulate solidification

with lever rule or Scheil

model

4 PANENGINE API 15

4.1 Functions for PanEngine Pointer

There are two functions associated with the

PanEngine

pointer: define a

PanEngine

pointer and delete a

PanEngine pointer. These two functions are global functions.

4.1.1 Define a PanEngine pointer

Name extern "C" PANENGINE API PanEngine* definePanEngineUser(char* msg)

Purpose define a PanEngine pointer and initialize it

Arguments msg message returned from PanEngine

A PanEngine pointer must be successfully initialized before PanEngines other functions can be used. If the

CompuTherm dongle is not attached to the computer, the initialization will fail.

4.1.2 Delete a PanEngine pointer

Name extern "C" PANENGINE API void deletePanEngineUser(PanEngine *pUser)

Purpose delete a PanEngine pointer after all calculations are done

Arguments PanEngine *pUser a defined and initialized PanEngine pointer

After a

PanEngine

pointer

pUser

is deleted, the system information inside

PanEngine

pointed to by

pUser

will be deleted and pUser will be a null pointer.

4.2 Functions for System

PanEngine

API functions in the system level manage the system related information, such as importing a

thermodynamic database and setting calculation conditions.

4.2.1 Set system configuration

Name string pe set configuration(map<string, string>& config)

Purpose set system configuration

Arguments config a map of pair of strings to define a configuration

One of the configurations is case sensitive of component names and phase names in a database. This can be

set with this function as:

map<string, string> config;

config["case_sensitive"] = "false";

s = user->pe_set_configuration(config);

which will convert all component and phase names into capital letters while reading the database.

4 PANENGINE API 16

4.2.2 Import a thermodynamic database

Name string pe import database(pair<string, string>& db, bool

append=false, const pair<string, string>& db to=pair<string,

string>())

Purpose import a thermodynamic database file in tdb format

Arguments db database file name; append append the database db to the database db to

Thermodynamic parameters are stored in files. The tdb type of file is a text file which can be modified by

the user using a text editor. The pdb type of file is an encrypted database. If

append=false

, import the

database in the file of db. If

append=true

, append the database in the file of

db

to the already imported

database from the file of db to.

4.2.3 Export a subsystem database into a file (tdb)

Name string pe export subsystem database (pair<string, string>& db, const

string subsystem name=string("sub.tdb"), const vector<string>&

comp name = vector<string>())

Purpose export a subsystem thermodynamic database in tdb format into a file

Arguments db

database file name;

subsystem name

subsystem database file name;

comp name

component names in the subsystem

After a thermodynamic database (

tdb

) is successfully loaded, a subsystem with selected components can be

exported into a database file with tdb format.

4.2.4 Get component names in a database

Name string pe export subsystem database (pair<string, string>& db, const

string subsystem name=string("sub.tdb"), const vector<string>&

comp name = vector<string>())

Purpose get all component names in a database

Arguments db database file name; comp name component names

This function gets all component names in a database with the file name of db.

4.2.5 Deactivate a component in a database

Name string pe deactivate component(string& comp name)

Purpose Deactivate a component in a database

Arguments comp name component to be deactivated

4 PANENGINE API 17

This function deactivates a component with the name of comp name in the current database.

4.2.6 Get phase names in a database

Name string pe get phase names(pair<string, string>& db, vector<string>&

phase name, vector<string> comp name = vector<string>())

Purpose get phase names in a database with a given set of components

Arguments db

database file name;

phase name

phase names;

comp name

selected component

names

If

comp name

is given, this function gets the phase names in the subsystem with the components of

comp name

in a database with the file name of

db

. Otherwise, the function gets all phase names in a database with the

file name of db.

4.2.7 Get and set phase statuses

Name string pe get phase status(pair<string, string>& db,

vector<pair<string, PAN PHASE STATUS>>& phase name status)

Purpose get phase status in a database

Arguments db database file name; phase name status vector of phases name and its status

Name string pe set phase status(pair<string, string>& db,

vector<pair<string, PAN PHASE STATUS>>& phase name status)

Purpose set phase status in a database

Arguments db database file name; phase name status vector of phases name and its status

These two functions get and set the phase statuses in a database. Phase status takes values of

P PHASE ENTERED

,

P PHASE SUSPENDED

,

P PHASE DORMANT

,

P PHASE FIXED

,

P PHASE STATUS NOT DEFINED

. See Pandat Users

Guide for definition of the phase status.

4.3 Functions for Point Calculation

PanEngine

uses a specially designed global optimization algorithm to find the most stable phase equilibrium

automatically without guessing initial values. It also provides functions for performing locally metastable

phase equilibrium calculations and other types of calculations. The point related calculations in

PanEngine

API are described below.

4 PANENGINE API 18

4.3.1 Set calculation condition

Name string pe set calculation condition(const Pan Calculation& calc)

Purpose set a calculation condition

Arguments calc calculation condition object

Calculation condition defines database to be used, units, selected components and phases, state space

(T, P,

xj). See test examples for detail.

4.3.2 Calculate a global phase equilibrium

Name string pe calc point global(shared ptr<P Point> p pt)

Purpose calculate a global phase equilibrium for a point

Arguments p pt a shared ptr of P Point to be calculated

This function calculates the global phase equilibrium according to the calculation condition. Information on

the calculated phase equilibrium is stored in p pt.

4.3.3 Calculate a global phase equilibrium with initials

Name string pe calc point global with initial point(shared ptr<P Point>

p pt)

Purpose calculate a global phase equilibrium for a point with initials

Arguments p pt a shared ptr of P Point to be calculated

This function calculates the global phase equilibrium with the initial conditions in

p pt

. Information on the

calculated phase equilibrium is also stored in

p pt

. With the initial values in

p pt

, the computational speed

is usually faster.

4.3.4 Calculate a local phase equilibrium

Name string pe calc point local with initial point(shared ptr<P Point>

p pt, bool given f=false)

Purpose

calculate a local phase equilibrium or parallel tangent equilibrium for a point with

initials

Arguments p pt a shared ptr of P Point to be calculated

given f false

for a local phase equilibrium and

true

for a parallel tangent

equilibrium

4 PANENGINE API 19

This function calculates the local phase equilibrium with the initial condition in

p pt

. Initial values in

p pt

is required for this function. The calculated phase equilibrium is stored in p pt.

4.3.5 Find the liquidus surface

Name string pe find liquidus surface(string& liquid phase name,

shared ptr<P Point> p pt)

Purpose find a liquidus surface point for given composition

Arguments liquid phase name

phase name of

liquid

;

p pt

a

shared ptr

of

P Point

for

liquid and primary phases

This function calculates the liquidus surface temperature for a point of with fixed composition.

PanEngine

will find the stable liquidus surface.

4.3.6 Find the liquidus slopes

Name string pe calc liquidus slope(string& liquid phase name, string&

solvent comp name, shared ptr<P Point> p pt)

Purpose calculate liquidus slopes on the liquidus surface

Arguments liquid phase name

phase name of liquid;

solvent comp name name of solvent

component; p pt a shared ptr of P Point for liquid with primary phase

This function calculates the liquidus slope along the directions of components on the liquidus surface for a

point with given composition. The slope along the direction of component j is defined as

s

j

=

∂T

liq

∂x

j

x

i

,i6=j,j6=solvent

(11)

where

T

liq

is the liquidus surface temperature and

x

j

is the mole fraction for the specified component

j

. Since

the molar fractions of components are dependent with each other by

P

k

x

k

= 1, the solvent component must

be specified. The slope along the direction of the solvent component will be treated as zero, s

solvent

= 0.

For example, in a ternary

A

-

B

-

C

system, if the component

A

is selected as the solvent component, the

slop of the liquidus surface along the direction of the component B is

s

B

=

∂T

liq

∂x

B

x

C

(12)

and the slope along the direction of the component C is

s

C

=

∂T

liq

∂x

C

x

B

(13)

4 PANENGINE API 20

The temperature change δT caused by the composition change of (δx

B

, δx

C

) will be calculated by

δT = s

B

δx

B

+ s

C

δx

C

(14)

The slopes in terms of weight fractions are also available, see test examples for detail.

Since PanEngine 2019, two new properties,

dxdT

and

dwdT

, have been added into

P Component

for

solidification simulation.

dxdT

and

dwdT

represent the change rates of the molar fraction and weight fraction

for a component in a phase with temperature during a solidification, respectively. These two variables can be

found in the definition of class P Component in the head file of Pan Global Def.h.

Since PanEngine 2020, another set of properties,

dxdT S

and

dxdT L

, and the corresponding properties in

weight fraction,

dwdT S

and

dwdT L

, have been added into

P Component

for solidification simulation.

dxdT S

and

dxdT L

represent the change rates of the molar fraction for a component in a solid phase and the liquid

phase with temperature during a solidification, respectively, assuming that the solid phase is the only phase

solidified from the liquid. In other words, these properties are calculated for the (local) equilibrium between

the liquid phase and the only solid phase, excluding other solid phases if they exist. Therefore, when there

is more than one solid phase solidified from liquid,

dxdT S

and

dxdT L

will have different values from

dxdT

.

dxdT S

,

dxdT L

,

dwdT S

and

dwdT L

are stored in the solid phase only. These variables can also be found in

the definition of class P Component in the head file of Pan Global Def.h.

When temperature decreases by

δT

during solidification, the composition changes of the solid phase and

the liquid phase can be calculated by

δx

s

j

= dxdT S δT (j = 1, 2, · · · , c) (15)

δx

l

j

= dxdT L δT (j = 1, 2, · · · , c) (16)

Test Example 4 has the printout of those properties in the callback function, progress 4.

4.4 Function for Solidification Simulation

PanEngine

has another API function for solidification simulations. There are two models available: lever rule

and Scheil.

Name String pe solidification simulation (Solidification Parameter&

s param, Pan Calculation& calc, vector<Solidification Node>&

solidification result)

Purpose simulate solidification with lever rule or Scheil model

Arguments s param

parameters for solidification simulation;

calc

calculation condition;

solidification result solidification results

Details on how to use this function will be demonstrated in test Examples 4 and 5.

4 PANENGINE API 21

4.5 Thermodynamic Factors

In Pandat, thermodynamic factors are available with the format ThF(*,*), which is defined by

ThF(x

i

, x

j

) =

∂µ

i

∂x

j

(i, j = 1, 2, · · · , c) (17)

where (

x

1

, x

2

, · · · , x

c

) are treated as the independent compositional variables. If the component 1 is assumed

to be the solvent component and its molar fraction

x

1

is taken as the dependent variable, the independent

compositional variables now are (

X

2

, X

3

, · · · , X

c

). Here we use capital

X

to distinguish this set of variables

from (x

1

, x

2

, · · · , x

c

). Then we have

∂µ

j

∂X

k

=

∂µ

j

∂x

k

−

∂µ

1

∂x

k

(j, k = 2, 3, · · · , c) (18)

=ThF(x

j

, x

k

) − ThF(x

1

, x

k

) (j, k = 2, 3, · · · , c) (19)

Now let’s see how to express the second derivatives of Gibbs free energy in terms of the thermodynamic

factors. If we use this compositional variable set (

X

2

, X

3

, · · · , X

c

), the first and second derivatives of

G

w.r.t.

X

j

are

∂G

∂X

j

=

c

X

i=2

∂G

∂x

i

∂x

i

∂x

j

+

∂G

∂x

1

∂x

1

∂x

j

(j = 2, 3, · · · , c) (20)

=

∂G

∂x

j

−

∂G

∂x

1

(j = 2, 3, · · · , c) (21)

=µ

j

− µ

1

(j = 2, 3, · · · , c) (22)

∂

2

G

∂X

j

∂X

k

=

c

X

i=2

∂(µ

j

− µ

1

)

∂x

i

∂x

i

∂x

k

+

∂(µ

j

− µ

1

)

∂x

1

∂x

1

∂x

k

(j, k = 2, 3, · · · , c) (23)

=(

∂µ

j

∂x

k

−

∂µ

1

∂x

k

) − (

∂µ

j

∂x

1

−

∂µ

1

∂x

1

) (j, k = 2, 3, · · · , c) (24)

=ThF(x

j

, x

k

) − ThF(x

1

, x

k

) − ThF(x

j

, x

1

) + ThF(x

1

, x

1

) (j, k = 2, 3, · · · , c) (25)

Thermodynamic factors,

ThF(*,*)

, are stored in the member variable of

m thermodynamic

in the class

P Phase Point

in the head file of

Pan Global Def.h

. Test Example 8 shows the thermodynamic factors of

the components in each stable phase point.

4.6 Hessian matrix of Gibbs energy

From the second derivatives of Gibbs free energy in previous section, Pandat has the Hessian matrix of

Gibbs free energy of a phase. Pandat also calculates the determinant, the eigenvalues and eigenvectors of the

Hessian matrix.

Since there is one dependent molar fraction for the molar fraction variables (

x

1

, x

2

, · · · , x

n

), one of the

components is selected as the dependent one. Without loss of generality,

x

n

is selected as the one, i.e., the

4 PANENGINE API 22

last component is considered as the solvent. Then, the second derivatives of Gibbs free energy of a phase

form the Hessian matrix, which is an (n-1) × (n-1) symmetrical matrix.

HSN =

∂

2

G

∂x

2

1

∂

2

G

∂x

1

∂x

2

∂

2

G

∂x

1

∂x

3

· · ·

∂

2

G

∂x

1

∂x

n-1

∂

2

G

∂x

2

∂x

1

∂

2

G

∂x

2

2

∂

2

G

∂x

2

∂x

3

· · ·

∂

2

G

∂x

2

∂x

n-1

∂

2

G

∂x

3

∂x

1

∂

2

G

∂x

3

∂x

2

∂

2

G

∂x

3

3

· · ·

∂

2

G

∂x

3

∂x

n-1

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

∂

2

G

∂x

n-1

∂x

1

∂

2

G

∂x

n-1

∂x

2

∂

2

G

∂x

n-1

∂x

3

· · ·

∂

2

G

∂x

2

n-1

(26)

Its determinant is given by

|HSN| =

∂

2

G

∂x

2

1

∂

2

G

∂x

1

∂x

2

∂

2

G

∂x

1

∂x

3

· · ·

∂

2

G

∂x

1

∂x

n-1

∂

2

G

∂x

2

∂x

1

∂

2

G

∂x

2

2

∂

2

G

∂x

2

∂x

3

· · ·

∂

2

G

∂x

2

∂x

n-1

∂

2

G

∂x

3

∂x

1

∂

2

G

∂x

3

∂x

2

∂

2

G

∂x

3

3

· · ·

∂

2

G

∂x

3

∂x

n-1

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

∂

2

G

∂x

n-1

∂x

1

∂

2

G

∂x

n-1

∂x

2

∂

2

G

∂x

n-1

∂x

3

· · ·

∂

2

G

∂x

2

n-1

(27)

The determinant of Hessian matrix for phase

f

is available from

HSN(@f)

. The value of

HSN(@f)

is independent

of the selection of the solvent component. However, eigenvalues and eigenvectors are dependent on the

selection of the solvent component.

A Hessian matrix has real eigenvectors and each eigenvalue has a corresponding eigenvector. The

eigenvalues and their eigenvectors are available from eVal(#*@f) and eVec(*#*@f).

Above Hessian matrix has eigenvalues of

eVal(#1@f)

,

eVal(#2@f)

,

· · ·

,

eVal(#n-1@f)

. Each eigenvalue

has an eigenvector. For example,

eVal(#1@f)

has an eigenvector of (

eVec(C

1

#1@f)

,

eVec(C

2

#1@f)

,

· · ·

,

eVec(C

n−1

#1@f)), where C

k

is the name of the k

th

component.

Test Examples 1 and 8 show how to get the values related to the Hessian matrix of Gibbs free energy of a

phase.

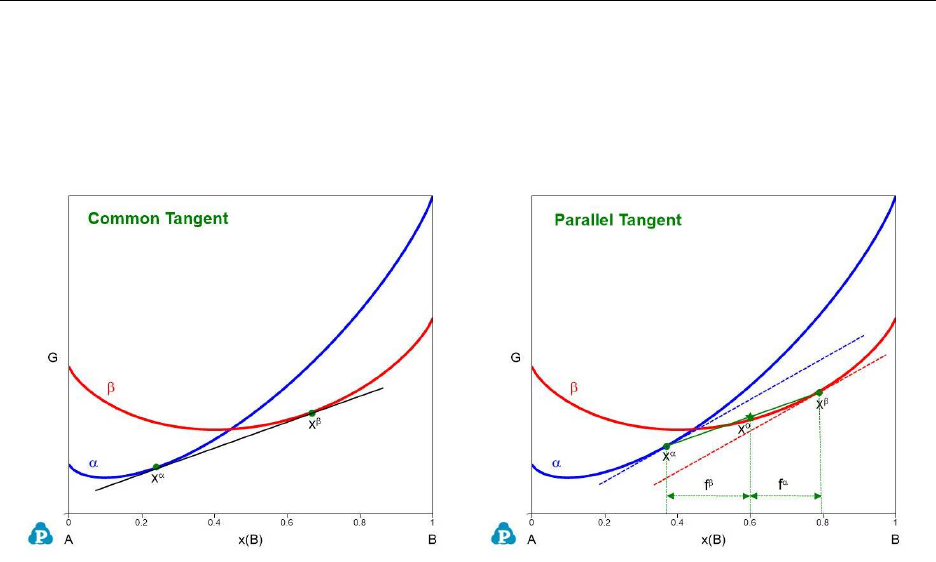

4.7 Parallel Tangent Equilibrium

In the phase field modeling of microstructure evolution, the equilibrium among phases at a interface is not

considered as a true phase equilibrium, where same component has same equilibrium chemical potential, i.e.,

common tangent (See Fig. 1(a)). Instead, the parallel tangent equilibrium is used at the interface during

phase field modeling.

Parallel tangent equilibrium assumes that the difference of the chemical potential of same component in

the phases at interface are same for all components, i.e.,

µ

α

i

− µ

β

i

= µ

α

j

− µ

β

j

(i, j = 1, 2, · · · , c) (28)

This constraint is equalvanlent to that the tangent lines to Gibbs free energy curves of phases are parallel to

each other, see Fig. 1(b). Therefore, this type of equilibrium is called parallel tangent equilibrium. For the

4 PANENGINE API 23

example of a parallel tangent equilibrium in Fig. 1(b), the overall composition,

x

◦

, and the phase fractions,

f

α

and

f

β

, are given and then the parallel tangents (dash lines) are calculated to get the equilibrium composition

of each phase, x

α

and x

β

.

Test Example 9 shows how to calculate a parallel tangent equilibrium.

(a) Common tangent equilibrium (b) Parallel tangent equilibrium

Figure 1: Two types of equilibria

5 EXAMPLES 24

5 Examples

This chapter demonstrates how to use

PanEngine

API functions with examples. There are seven test examples.

The main program (

main.cpp

) is for user to select which example to run. All the source files (

*.cpp

) can be

found in the folder /source/. Following sections give a brief review of each example.

5.1 Test Example 1

This first test example is in file of

PanEngineTest 1.cpp

. It uses a number of point calculations to demonstrate

the following functions:

// Define a PanEngine user pointer

user = definePanEngineUser(msg);

// Set PanEngine configuration

s = user->pe_set_configuration(config);

// Import a database

s = user->pe_import_database(db);

// Set calculation condition

s = user->pe_set_calculation_condition(calc);

// Calculate a global phase equilibrium

s = user->pe_calc_point_global(calc_point);

// Calculate a global phase equilibrium with initial

s = user->pe_calc_point_global_with_initial_point(calc_point);

// Delete a PanEngine user pointer

deletePanEngineUser(user);

It demonstrates how to set up calculation conditions. The example shows how to get the physical properties

of molar volume and density. The Hessian matrix of Gibbs free energy of a phase, its determinant, eigenvalues

and corresponding eigenvectors are also available. After

sys ptr->m condition->m driving force

is set to

be true, the driving force for a phase with respect to an equilibrium state can be obtained.

5.2 Test Example 2

The second test example is in file of

PanEngineTest 2.cpp

. It mainly demonstrates how to use a “

for

” loop

to calculate multiple points using the function

pe calc point global with initial point

. However, the

first point has to be calculated with the function pe calc point global to get initial point.

5 EXAMPLES 25

5.3 Test Example 3

The third test example is in file of

PanEngineTest 3.cpp

. It demonstrates how to calculate local phase

equilibria for a point at different temperatures and multiple points with different compositions using the

function of

pe calc point local with initial point

. Similar to the previous example (Test Example 2),

the first point has to be calculated with the function pe calc point global to get initial point.

5.4 Test Example 4

The fourth test example is in file of

PanEngineTest 4.cpp

. Most of the codes in this file are for setting solidifi-

cation conditions and parameters, such as database name, units, alloy compositions, solvent component, solidifi-

cation model, and step size. The major function used in this test example is

pe solidification simulation

.

The solidification result could be output to a file with the function

string output result(string file name, vector<Solidification Node>& solidification result)

which is defined in this example file.

The function

bool progress 4(char* msg, Solidification Parameter& sp, vector<Solidification Node>& node)

is a callback function which will be called from

PanEngine

to send back the intermediate results during

simulation.

5.5 Test Example 5

The fifth test example is in file of

PanEngineTest 5.cpp

. This example is also for solidification simulation

and similar to the previous one. It demonstrates how to simulate solidification processes for multiple alloys

with different compositions.

The function

bool progress 5(char* msg, Solidification Parameter& sp, vector<Solidification Node>& node)

is the callback function.

5.6 Test Example 6

The sixth test example is in file of

PanEngineTest 6.cpp

. This example demonstrates how to find the

liquidus surface and calculate liquidus slops using the following two functions:

s=user->pe_find_liquidus_surface(liquid_name, calc_point)

and

s=user->pe_calc_liquidus_slope(liquid_name, solvent_name, p_pt)

The example uses a double “

for

” loops to calculate the liquidus surface points and slops for a series of

points in the Al-Mg-Zn system.

5 EXAMPLES 26

5.7 Test Example 7

The seventh test example is in file of

PanEngineTest 7.cpp

. This example uses three stages to locate a point

on the liquidus surface in the

Al-Mg-Zn

ternary system where the temperature reaches the minimum. The

first stage of search uses the step size of

dx=0.1

. The second stage uses step size of

dx=0.01

to search in the

compositional neighborhood of the found composition in the first stage. And the third stage uses the step

size of

dx=0.001

to search in the compositional neighborhood of the found composition in the second stage.

Even through this method is of brute-force, it works fine for such a simple problem. The major function used

in this example is pe find liquidus surface.

5.8 Test Example 8

The eighth test example is in file of

PanEngineTest 8.cpp

. This example demonstrates how to obtain the

thermodynamic properties such as thermodynamic factors and Hessian matrix, and the kinetic properties

such as mobility and diffusivity. The example calculates the thermodynamic factor, Hessian matrix, mobility,

and diffusivity for an alloy in the

Fe-Ni-Cr

system. For the calculation of Hessian matrix, mobility and

diffusivity, the name of the solvent component has to be defined, as is given below,

sys_ptr->m_condition->m_solvent = string("Ni");

which is in the function of set calculation condition 8.

The example shows how to extract those properties from a calculated point.

5.9 Test Example 9

This last test example is in file of

PanEngineTest 9.cpp

. This example demonstrates how to calculate a

parallel tangent equilibrium.

The example calculates the two-phase parallel tangent equilibrium between Fcc and gamma double prime

(γ

00

) in a pseudo-ternary Ni-Al-Nb. The common tangent equilibrium is first calculated from

s = user->pe_calc_point_global(calc_point);

to get the initial values of the parallel tangent equilibrium. Then, reset the phase fractions of the two phases

by

calc_point->m_ppt[0]->m_f = 0.5;

calc_point->m_ppt[1]->m_f = 0.5;

Call the function of calculating point local with initial point

s = user->pe_calc_point_local_with_initial_point(calc_point, true);

with a

true

value for the second argument to calculate the parallel tangent equilibrium. When the second

argument is

true

, the function will calculate the parallel tangent equilibrium. If the second argument is

false, the function will calculate the normal local common tangent equilibrium.

Example 9 continues with a set of randomly generated temperatures, overall compositions and phase

fraction to calculate the parallel tangent equilibria.

CompuTherm, LLC

Copyright

c

2012-2020