109

4 PanOptimizer

PanOptimizer is a module of Pandat

TM

software designed for optimizing

thermodynamic, kinetic and thermo-physical model parameters using

experimental data. The module allows users to develop their own databases or

model parameters for customized applications. This module is also easy to

master by students who want to learn thermodynamic modeling.

4.1 Features of PanOptimizer

Derived from the maximum likelihood principle, when the discrepancies

between model-calculated and experimental values are assumed to be

independent, identically distributed with a normal distribution function, a set

of model parameters with the best fit to the given experimental data can be

obtained by the least square method. In the real world the experimental data

may come from different sub-populations for which an independent estimate of

the error variance is available. In this case, a better estimate than the ordinary

least squares (OLS) can be obtained using weighted least squares (WLS), also

called generalized least squares (GLS), then the sum of the squares can be

written as

2

1

1

( ; , )

2

m

j j j j

j

w y x T c

=

−

(4.1)

The idea is to assign each observation a weight factor that reflects the

uncertainty of the measurement. According to our previous experiences this

method is efficient and reliable in the optimization of model parameters and

develop variety of databases.

4.2 PanOptimizer Functions

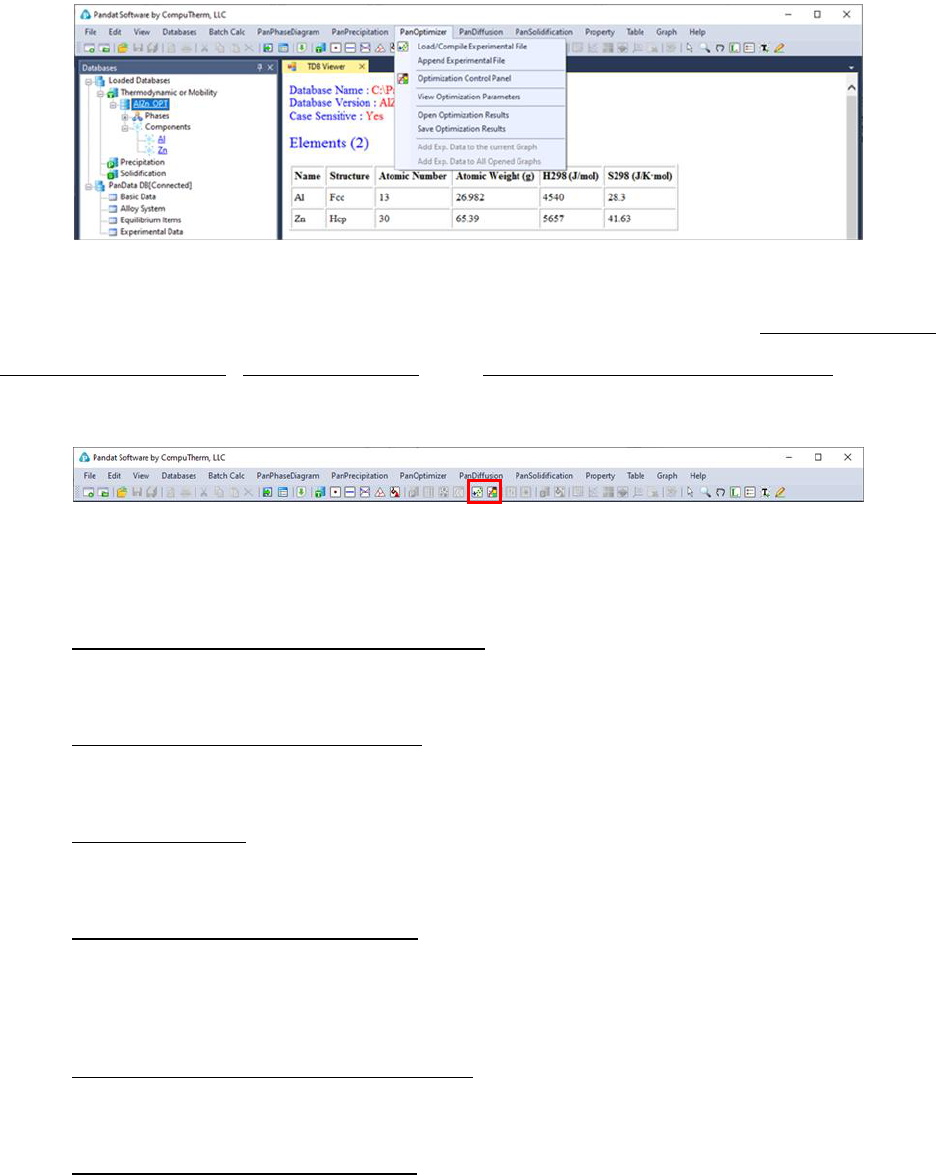

The major functions included in the PanOptimizer menu are shown in Figure

4.1:

110

Figure 4.1 The PanOptimizer Menu

The shortcut of the three commonly used functions Load/Compile

Experimental File, Rough Search and Optimization Control Panel are also

displayed in the Toolbar as shown in Figure 4.2.

Figure 4.2 PanOptimizer toolbar

The functionality of each function is given below:

➢ Load/Compile Experimental File: Load/Compile experimental data file

for model parameter optimization

➢ Append Experimental File: Append more experimental data from

different data file

➢ Rough Search: Global/Local search of initial values of model parameters

for obtaining the phase diagram topology of a system

➢ Optimization Control Panel: Allow user to set boundaries for the model

parameters to be optimized, select experimental data to be used, and

assign weight to each set of experimental data

➢ View Optimization Parameters: View/Edit model parameters to be

optimized

➢ Open Optimization Results: Open the saved intermediate optimization

results including the model parameters and experimental data

111

➢ Save Optimization Results: Save the intermediate optimization results

during the optimization process including the model parameters and

experimental data

4.3 Step by Step Instruction for

Optimization

In general, user should follow a few steps below to perform the model

parameter optimization.

4.3.1 Step 1: File preparation

4.3.1.1 Prepare the thermodynamic database file (.TDB)

In order to do the optimization, user must first define the model parameters to

be optimized in the thermodynamic database (.tdb). The model parameters to

be optimized can be defined in Pandat

TM

workspace where all the built-in

keywords are automatically highlighted. It can also be done through outside

text editor such as “Notepad”. Each model parameter that needs to be

optimized is defined by the keyword “Optimization”. The format of defining a

model parameter is:

Optimization [parameter name][low bound][initial value][high bound] N !

A definition sample for liquid phase in binary Al-Zn system is given as follows

$ Keyword Name Low Bound Init. Value High Bound

Optimization LIQ_AA 0 0; 60000 N !

Optimization LIQ_AAT -20 0; 20 N !

Optimization LIQ_BB -60000 0; 60000 N !

Optimization LIQ_BBT -20 0; 20 N !

Phase Liquid % 1 1 !

Constituent Liquid : Al, Zn : !

112

Optimization G(Liquid,Al;0) 298.15 G_Al_LIQUID; 6000 N !

Optimization G(Liquid,Zn;0) 298.15 G_Zn_LIQUID; 6000 N !

Optimization G(Liquid,Al,Zn;0) 298.15 LIQ_AA + LIQ_AAT*T; 6000 N !

Optimization G(Liquid,Al,Zn;1) 298.15 LIQ_BB + LIQ_BBT*T; 6000 N !

Two modes of optimization are allowed in the current version: one is “bounded”

optimization and the other one is “no bound” optimization. Even though the

low and high bounds will be in effect in the bounded optimization only, they

are required for definition of model parameters in a TDB file. The model

parameters can be named at users’ choices. It is suggested that the name is

related to the phase to be optimized. Note: User may use “%” to denote the

major species in a sublattice of a phase in a TDB file. PanOptimizer will

automatically assign the initial values for the major species denoted by “%”. The

following example means Zn is the major species in the first sublattice of the

Hcp phase:

Phase Hcp % 2 1 0.5 !

Constituent Hcp: Al, Zn%: Va:!

4.3.1.2 Prepare the experimental file (.POP)

Users need to provide their own experimental data file for optimization of model

parameters. The most widely accepted format for experimental data file in the

CALPHAD society is a POP file. PanOptimizer accepts most of the keywords in

the POP format and adds a few special keywords. In a POP file, a phase can

have four statuses: ENTERED, FIXED, DORMANT, and SUSPEND. The first

two statuses were used most frequently. When phases are in the ENTERED

status, PanOptimizer does not require user to input any initial values for

calculation since the truly stable phase equilibria will be found automatically

in this case with the built-in global optimization algorithm. On the other hand,

for those phases in FIXED or DORMANT status, the initial values should be

provided by the user. Example POP files are provided in the installation

dictionary of Pandat

TM

.

113

4.3.2 Step 2: Carry out optimization

Once above files have been prepared, user is ready to carry out optimization:

4.3.2.1 Load thermodynamic database file

First of all, the database file (.TDB) containing the phases to be modeled is

loaded by click the button. This database file defines the model type and

model parameters of each phase in the system. The model definition is

consistent with the currently accepted format in the CALPHAD society, and the

model parameters can be real numbers or variables to be optimized.

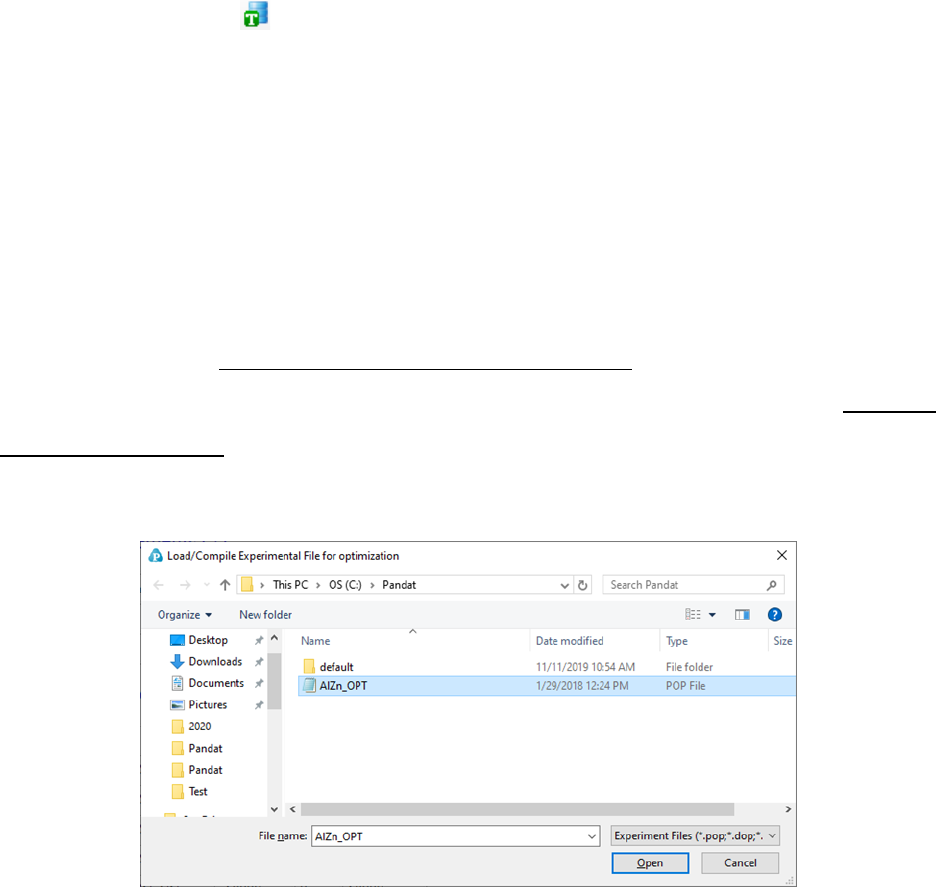

4.3.2.2 Load and compile experimental file

After loading a TDB file with defined model parameters to be optimized, users

should then load and compile the experimental POP file. Go to PanOptimizer

menu and choose Load/Compile Experimental File, user can then select the

POP file already prepared as shown in Figure 4.3. User can also choose Append

Experimental File to append new experimental data stored in a separate file to

the currently opened POP file.

Figure 4.3 Dialog window of loading an experimental file

114

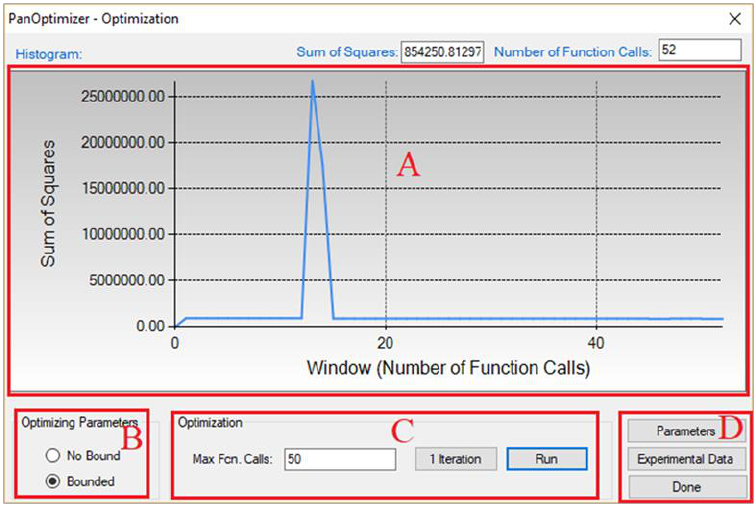

4.3.2.3 Perform Optimization

Once the TDB file and the experimental POP file are loaded, user is ready to do

the optimization. In the current version of PanOptimizer, the optimization is

controlled through the optimization control panel as shown in Figure 4.4.

There are four control areas in the optimization control panel. They are:

Histogram (A), Bound/Unbound Variables (B), Optimization (C), and

Optimization Results (D).

Figure 4.4 The optimization control panel.

4.3.2.4 Histogram (A)

Histogram is for displaying and tracing the history of the discrepancy between

model-calculated values and experimental data, which is characterized by the

Sum of Squares displayed during the whole optimization procedure. The

histogram plots the sum of squares vs. the number of function calls. The exact

value of the sum of squares in the current step can be found at the up-right

corner of this area.

115

4.3.2.5 Free Bound/Unbound Variables (B)

The user can choose the model parameters to be optimized in either the

bounded or the unbounded mode. In the bounded mode, the low and high

bounds defined in a TDB file will take into effects.

4.3.2.6 Optimization (C)

The goal of the optimization process is to obtain an optimal set of model

parameters so that the model calculated results can best fit the given

experimental measurements. The optimization process can be controlled by

choosing 1 Iteration or Run. With 1 Iteration, the maximum number of

function calls is set to be 2(N+2), where N is the number of model parameters

to be optimized. The user can click Run mode several times until the optimal

solution is found or the designated maximum number of function calls is

reached.

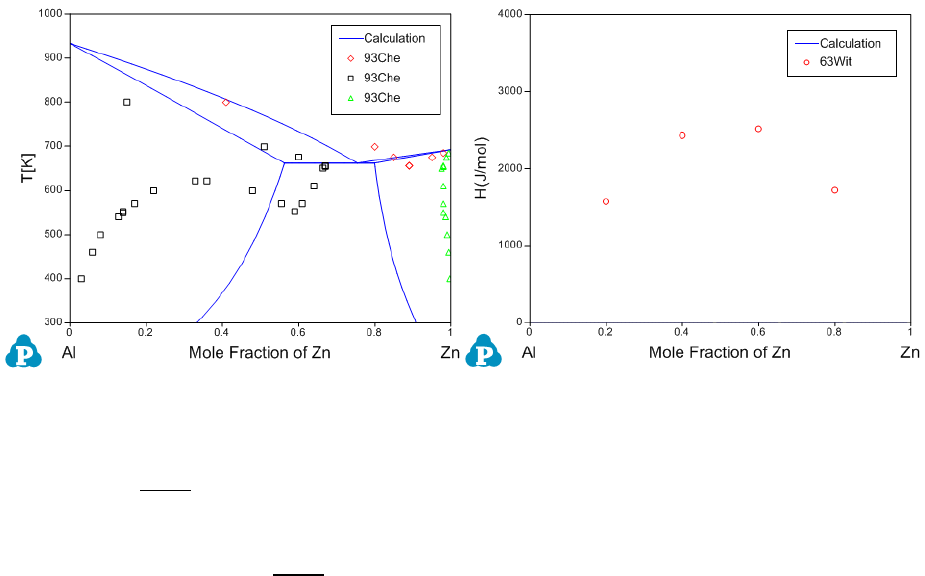

Here we take the binary Al-Zn system as an optimization example. The TDB and

POP files are available at the installing directory of Pandat

TM

“/Pandat_Examples/PanOptimizer/”. In this example, there are totally 11

parameters to be optimized and all the initial values are set to be zero. The

available experimental data include:

➢ mixing enthalpy of liquid phase at 953K

➢ invariant reaction at 655K: Liquid → Fcc + Hcp

➢ invariant reaction at 550K: Fcc#2 → Fcc#1 + Hcp

➢ tie-lines: Fcc#1+Fcc#2, Liquid + Fcc, Liquid + Hcp and Hcp + Fcc

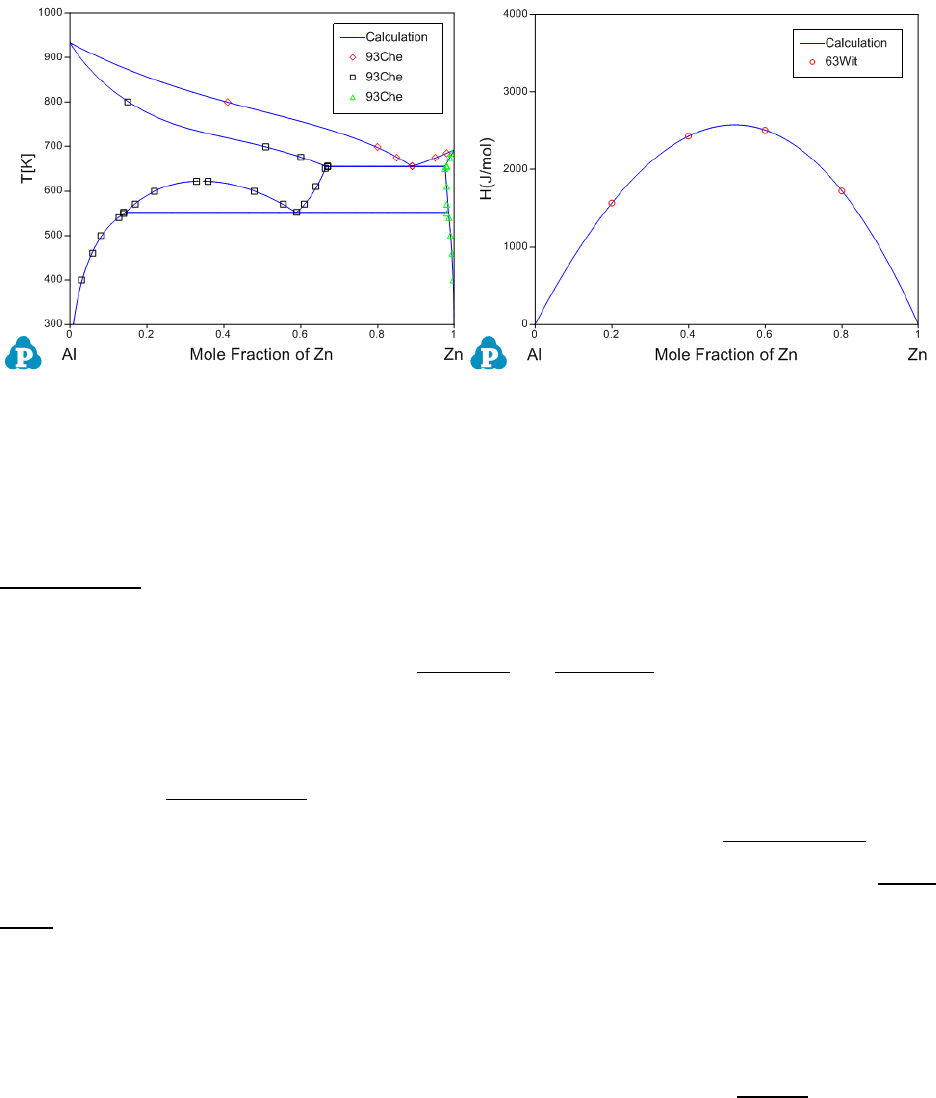

Before the optimization, user may want to check the calculated results using

the initial set of model parameters without optimization. Phase diagram

calculation can be done through 2-D section calculation, and enthalpy

calculation can be done through the 1-D line calculation. Figure 4.5 shows the

calculated Al-Zn phase diagram and enthalpy of mixing for liquid phase at

116

953K along with the given experimental data, respectively. The parameters

before optimization result in large discrepancies between the calculated values

and the experimental measurements. Optimization of these model parameters

(initially set as zero) is needed.

Figure 4.5 Comparisons between calculated results and experimental data

before the optimization

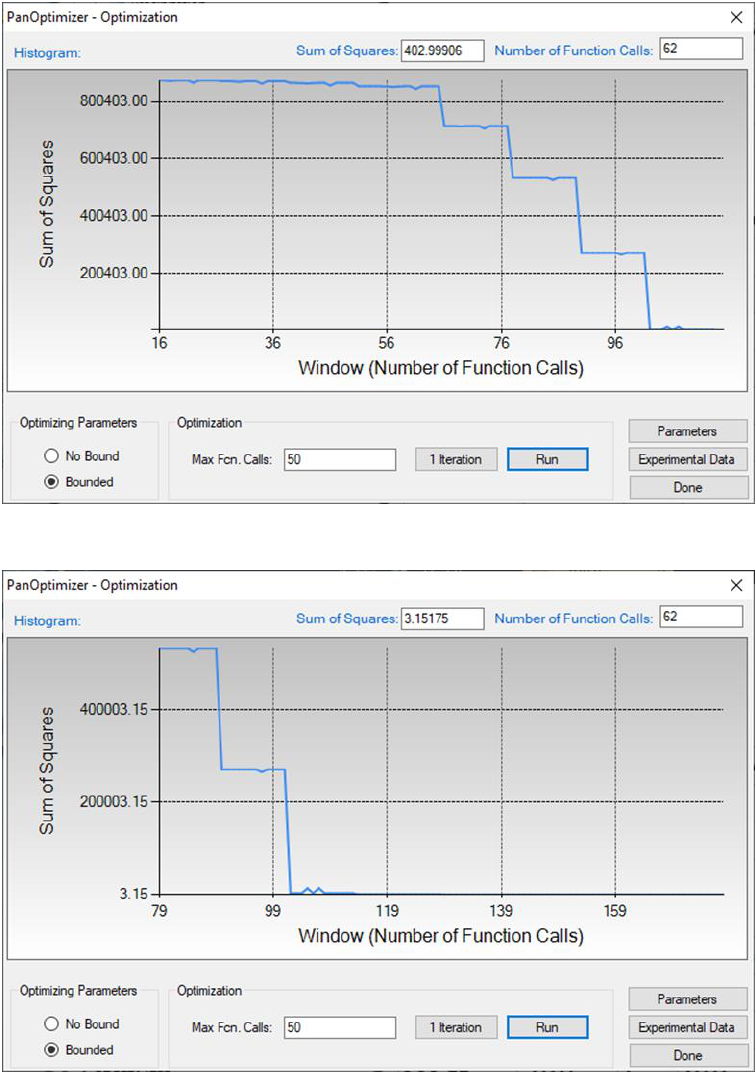

By clicking Run twice (two rounds), and each run performs 50 function calls,

the sum of squares decreases from 854251 to 403 as shown in Figure 4.6.

After another round of Run, the sum of squares decreases from 403 to 3.15 as

shown in Figure 4.7. Now, we can do the real time calculation using the

instantly obtained optimized parameters. The two comparisons in Figure 4.8

show excellent agreements between the calculated results and the measured

data. By selecting the command from PanOptimizer menu: PanOptimizer →

Add Exp. Data to the current Graph, user can add the corresponding

experimental data defined in the pop file directly to the calculated diagram for

comparison.

117

Figure 4.6 The sum of squares after two rounds of optimization

Figure 4.7 The sum of squares after another two rounds of optimization

118

Figure 4.8 Comparisons between the calculated results and the experimental

data after optimization

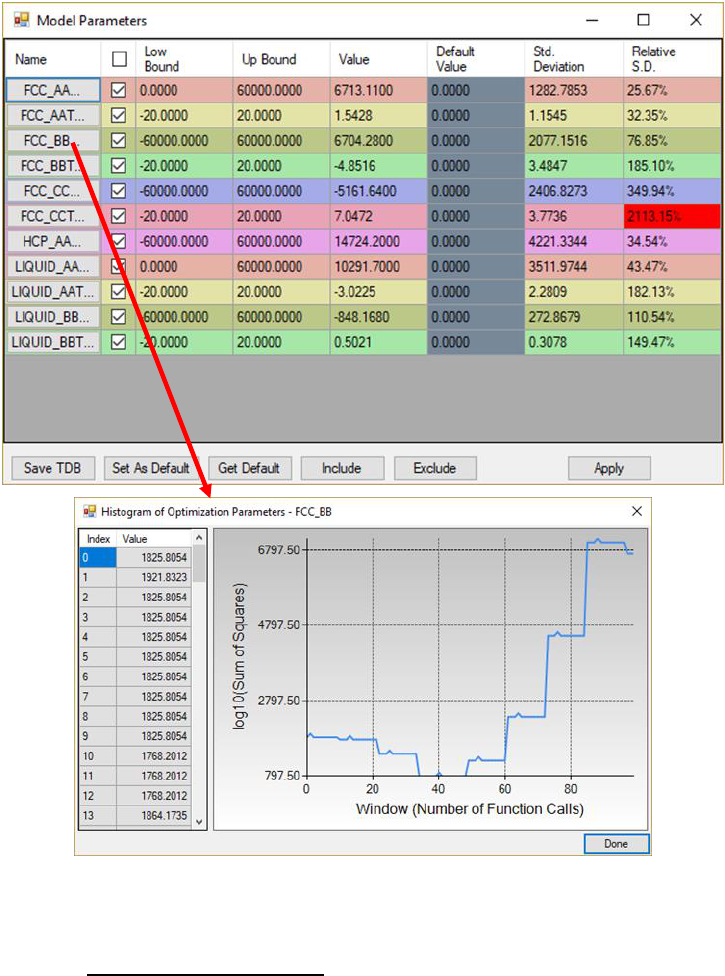

4.3.2.7 Optimization Results (D)

During optimization, user can check model parameters through the

Parameters button as shown in Figure 4.4. For each model parameter, user

can change its low bound, upper bound and initial value in the dialog window

as shown in Figure 4.9. User can Include or Exclude a certain parameter in

the optimization through the “check box” in front of the parameter. If a set of

optimized parameters is satisfactory, user can save this set of values as default

ones through Set Default shown in Figure 4.9. Otherwise, user can reject this

set of values and go back to previous default values through Get Default. User

also can save the TDB file with the optimized model parameters through Save

TDB. The standard deviation and relative standard deviation (RSD) of each

parameter are computed during optimization. The parameter evolution during

the last 100 iterations can be tracked by clicking the parameter name in the

table as indicated in Figure 4.9. It should be noted that any changes on model

parameters made by user will take into effect only after the “Apply” button is

clicked.

119

Figure 4.9 Dialog windows of Model Parameters and Histogram of Optimization

Parameters

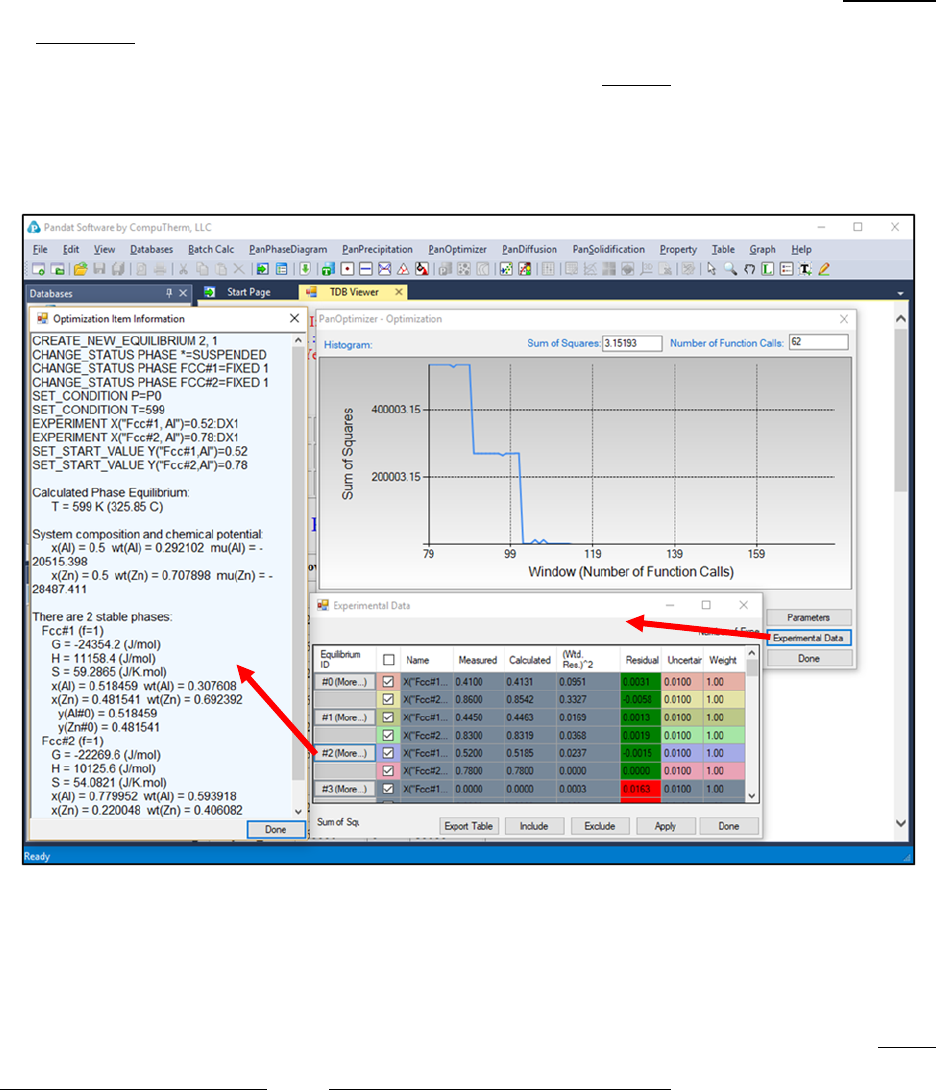

By clicking the Experimental Data button on Figure 4.7, a table which lists

the calculated values together with the experimental data will pop out as

shown in Figure 4.10. This table allows user to view how well the current

optimized parameters describe each set of experimental data. If the discrepancy

is found to be large and not satisfied for a certain set of data, a larger weight

factor for this set of data can be given in the next round of optimization.

Through the column of “Residual” shown in Figure 4.10, user can see different

color after each comparison. The green means satisfactory results are achieved,

120

while the red color means large deviation remaining. Again, user can Include

or Exclude a certain experimental data set for the optimization through the

check box in front of each experimental data Name. Also, more detailed

experimental data information can be viewed by clicking the experimental data

ID in the table.

Figure 4.10 Dialog windows of Experimental Data and Optimization Item

Information

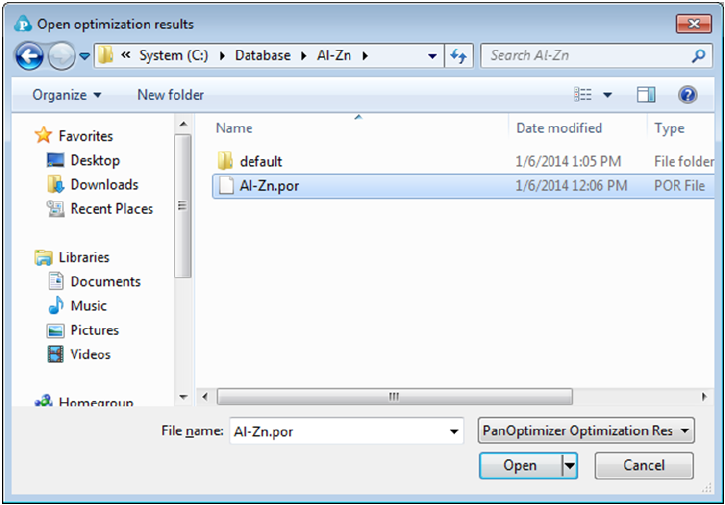

4.3.3 Step 3: Save/Open Optimization Results

During optimization, the user may save and load optimization file through Save

Optimization Results and Open Optimization Results (see Figure 4.11). The

optimization results file has the extension name of POR that can only be read

by PanOptimizer. Intermediate optimization results can be saved and restored

through these two operations. These functions are very useful especially when

a user is optimizing model parameters for a complicated system. The user can

121

always go back to a certain middle stage and restart from there. This will save

user’s time by avoiding some repeated work.

Figure 4.11 Dialog window of open the saved optimization results

4.4 User-defined Property Optimization

The parameters for physical property, kinetic property, and user-defined

property can also be optimized with respect to experimental data just like the

parameters in a thermodynamic database. User can refer to section 8.4 for the

format to define user-defined property in a database. Similar to the

optimization of thermodynamic model parameters, user needs to define the

parameters to be optimized in the database and prepare a pop file with

corresponding experimental data. An example for the parameter definition in

the database is shown below.

$Thermal conductivity of pure element in the Fcc phase

PARAMETER ThCond(Fcc,Al;0) 298.15 +311.72511-0.09661*T-13510.26/T; 3000 N !

PARAMETER ThCond(Fcc,Cu;0) 298.15 +417.28065-0.06598*T+944.065/T; 3000 N !

122

$Thermal conductivity interaction parameters for Fcc phase to be optimized

OPTIMIZATION Fcc_TC 0 0; 60000 N !

OPTIMIZATION Fcc_TCT -50 -24.6; 0 N !

OPTIMIZATION Fcc_TC_1 -60000 0; 0 N !

OPTIMIZATION Fcc_TCT_1 0 28; 50 N !

PARAMETER ThCond(Fcc,Al,Cu;0) 298.15 +Fcc_TC+Fcc_TCT*T; 3000 N !

PARAMETER ThCond(Fcc,Al,Cu;1) 298.15 +Fcc_TC_1+Fcc_TCT_1*T; 3000 N !

And an example pop file for the experimental data is shown below.

$Thermal Conductivity of the Fcc phase at 1000K

TABLE_HEAD

CREATE_NEW_EQUILIBRIUM @@,1

CHANGE_STATUS PHASE * = S

CHANGE_STATUS PHASE Fcc = FIX 1

SET_CONDITION T=1000, P = P0, X(Fcc,Cu) = @1

EXPERIMENT ThCond(Fcc)= @3 : @4

TABLE_VALUES

$ x(Cu) x(Al) TC DTC

0.05 0.95 194 50

0.1 0.9 295 50

0.2 0.8 750 50

0.8 0.2 3116 50

0.9 0.1 2122 50

0.95 0.05 1343 50

TABLE_END

The optimization procedure is the same as that for thermodynamic parameters.

User may refer to the previous section for details and get the optimization

result step by step.