40

3 PanPhaseDiagram

3.1 Thermodynamic Database

PanPhaseDiagram is for phase diagram and thermodynamic property

calculation. Thermodynamic database is the prerequisite to fulfill such

calculations. A thermodynamic database represents a set of self-consistent

Gibbs-energy functions with optimized thermodynamic-model parameters for

all the phases in a system. The advantage of CALPHAD method is that the

separately-measured phase diagrams and thermodynamic properties can be

represented by a unique “thermodynamic description” of the materials system

in question. More importantly, on the basis of the known descriptions of the

constituent lower-order systems, the thermodynamic description for a higher-

order system can be obtained via an extrapolation method [1989Cho]. This

description enables us to calculate phase diagrams and thermodynamic

properties of multi-component systems that are experimentally unavailable.

In the following, thermodynamic models used to describe the disordered phase,

ordered intermetallic phase, and stoichiometric phase are presented. The

equations are given for a binary system, and they can be extrapolated to a

multi-component system using geometric models [1975Mug, 1989Cho].

The Gibbs energy of a binary disordered solution phase can be written as:

,

,,

ln ( )

ov

m i i i i A B v A B

i A B i A B v

G x G RT x x x x L x x

==

= + + −

(3.1)

where the first, second and third terms on the right hand of the equation

represent, respectively, the reference states, the entropy of ideal mixing, and

the excess Gibbs energy of mixing. Here x

i

is the mole fraction of a component i,

o

i

G

,

is the Gibbs energy of a pure component i, with an φ structure, R is the

gas constant, T is the absolute temperature, L

ν

is the interaction coefficient at

the polynomial series of the power ν. When ν = 0, it is a regular solution model,

41

and when ν = 0 and 1, it is a sub-regular solution model. Equation 3.1 can be

extrapolated into a multi-component system using geometric models, such as

the Muggianu model [1975Mug]. Ternary and higher-order interaction

parameters may be necessary to describe a multi-component solution phase.

An ordered intermetallic phase is described by a variety of sublattice models,

such as the compound-energy formalism [1979Ansara, 1988Ansara] and the

bond-energy model [1992Oates, 1995Chen]. In these models, the Gibbs energy

is a function of the sublattice species concentrations and temperature. The

Gibbs energy of a binary intermetallic phase, described by a two-sublattice

compound-energy formalism,

qp

BABA ),(:),(

, can be written as:

BABA

II

B

II

A

I

B

I

A

v

v

BAi

vII

B

II

A

II

B

II

A

BAi

I

i

v

v

jBA

vI

B

I

A

II

j

I

B

BAj

I

A

BAi

II

i

II

i

BAi

I

i

I

i

BAi BAj

ji

II

j

I

im

Lyyyy

LyyyyyLyyyyy

yy

qp

q

yy

qp

p

RTGyyG

,:,

,:

,

:,

,

,,, ,

:

)()(

]lnln[

+

−+−+

+

+

+

+=

==

=== =

(3.2)

where

I

i

y

and

II

i

y

are the species concentrations of a component,

i

, in the first

and second sublattices, respectively. The first term on the right hand of the

equation represents the reference state with the mechanical mixture of the

stable or hypothetical compounds: A,

qp

BA

,

qp

AB

, and B.

ji

G

:

is the Gibbs energy

of the stoichiometric compound,

qp

ji

, with an

structure. The value of

ji

G

:

can

be obtained experimentally if

qp

ji

is a stable compound; or it can be obtained

by ab initio calculation if

qp

ji

is a hypothetical compound. Sometimes,

ji

G

:

are

treated as model parameters to be obtained by optimization using the

experimental data related to this phase. The second term is the ideal mixing

Gibbs energy, which corresponds to the random mixing of species on the first

and second sublattices. The last three terms are the excess Gibbs energies of

mixing. The

""L

parameters in these terms are model parameters whose values

are obtained using the experimental phase-equilibrium data and

thermodynamic-property data. These parameters can be temperature

42

dependent. In this equation, a comma is used to separate species in the same

sublattice, whilst a colon is used to separate species belonging to different

sublattices. The compound-energy formalism can be applied to phases in a

multi-component system by considering the interactions from all the

constituent binaries. Additional ternary and higher-order interaction terms

may also be added to the excess Gibbs energy term.

For a reciprocal system with two sublattices, sometimes the interactions among

the two species on each sublattice are considered,

. The interaction

parameter is expressed as [2007Luk]

(3.3)

Pandat treats the term

as the interaction on the first sublattice

and the term

as the interaction on the second sublattice.

Pandat does not use the alphabetical order of species.

The Gibbs energy of a binary stoichiometric compound

pq

AB

,

m

G

, is described

as a function of temperature only:

,

()

m i i f p q

i

G x G G A B

= +

(3.4)

where

i

x

is the mole fraction of component i (i=p if it is A, and i=q if it is B), and

,

i

G

represents the Gibbs energy of component i with

structure;

()

f p q

G A B

,

which is normally a function of temperature, represents the Gibbs energy of

formation of the stoichiometric compound. If

()

f p q

G A B

is a linear function of

temperature:

( ) ( ) ( )

f p q f p q f p q

G A B H A B T S A B = −

(3.5)

then

()

f p q

H A B

, and

()

f p q

S A B

are the enthalpy and entropy of formation of the

stoichiometric compound, respectively. Equation (3.3) can be readily extended

to a multi-component stoichiometric compound phase.

43

The strategy of building a multi-component thermodynamic database starts

with deriving the Gibbs energy of each phase in the constituent binaries. There

are

2

n

C

constituent binaries in an n-component alloy system, where

)!(!

!

ini

n

C

i

n

−

=

(3.6)

To develop a reliable database, the Gibbs energies of these binaries must be

developed in a self-consistent manner and be compatible with each other.

Three binaries form a ternary, and a preliminary thermodynamic description

can be obtained by combining the three constituent binaries using geometric

models, such as the Muggianu model [1975Mug]. In some cases, a ternary

database developed in this way can describe a ternary system fairly well, while

in most cases, ternary interaction parameters are necessary to better describe

the ternary system. If a new phase appears in the ternary, which is not in any

of the constituent binaries, a thermodynamic model is selected for this ternary

phase, and its model parameters are optimized using the experimental

information for this ternary phase. There are a total of

3

n

C

ternary systems in

an n-component system. After thermodynamic descriptions of all

3

n

C

ternaries

for an n-component system are established, the model parameters are simply

used to describe quaternary and higher-order systems using an extrapolation

approach. High-order interaction parameters are usually not necessary

because although interactions between binary components are strong, in

ternary systems they become weaker, and in higher-ordered systems they

become negligibly weak [1997Kattner, 2004Chang]. It is worth noting that the

term, “thermodynamic database” or simply “database”, is usually used in the

industrial community instead of “thermodynamic description”, particularly for

multi-component systems.

At CompuTherm, multi-component databases have been developed for variety

of alloys, such as for Al-alloys, Co-alloys, Cu-alloys, Fe-alloys, Mg-alloys, Mo-

alloys, Nb-alloys, Ni-alloys, Ti-alloys, TiAl-alloys, high entropy alloys, and

44

solder alloys. Information for these databases is available in the

“Thermodynamic Database User’s Guide” from CompuTherm.

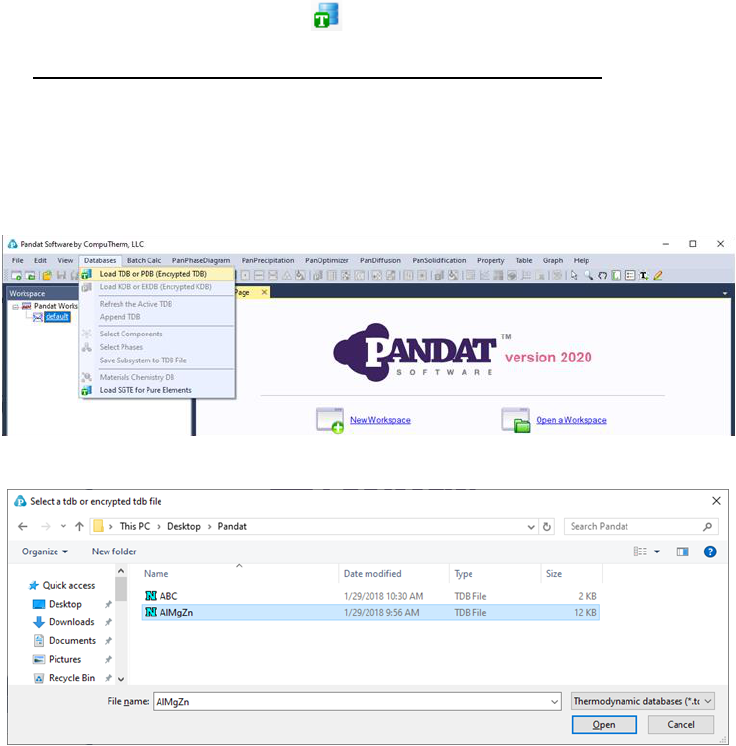

3.2 Thermodynamic Calculation

3.2.1 Load Database

Pandat

TM

can load both PDB and TDB database files. This command can be

accessed through the toolbar icon . User can also load a database file using

the Menus Database→Load TDB or PDB (Encrypted TDB) as shown in Figure

3.1. Select a database file from hard drive and click open button, or just double

click the database file. Users can store the databases in any directory in the

computer.

Figure 3.1 Load a database from hard drive through Menus

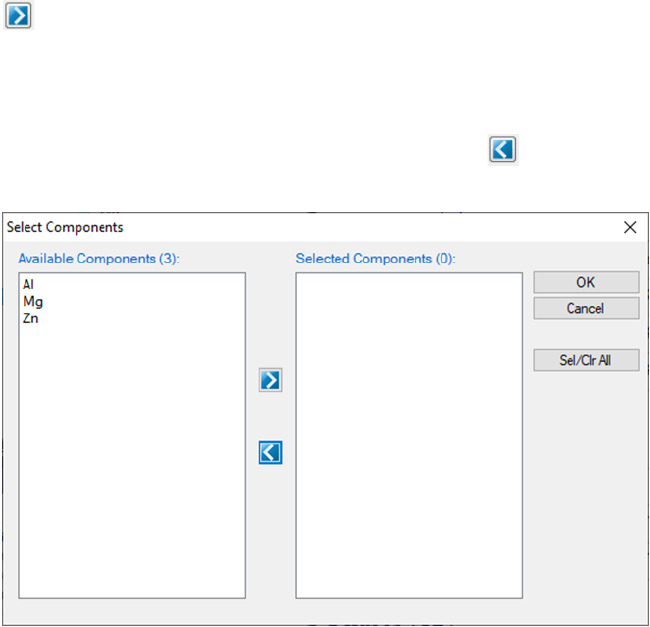

Immediately after a database is successfully loaded, a popup window shown in

Figure 3.2 will ask the user to select the components for subsequent

calculations. To add a component to the list of selected components, click on

the component on the list of Available Components on the left column, and

45

click on the button to send them to the Selected Components on the right

column. To select several components at one time, hold the <Ctrl> key and use

mouse to select multiple components. To remove a component from selected

components list, use mouse to select it, and click the button.

Figure 3.2 Select components for further calculation

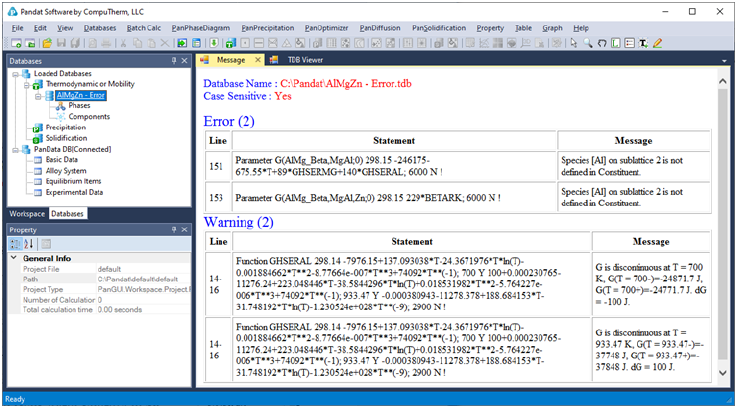

While loading a database file, Pandat

TM

checks the self-consistency of the

database. A message will be displayed if the database is not internally

consistent such as duplicated definitions of a function, missing definition of

components or species in a sublattice, and so on. There are two types of

messages: Error and Warning, as shown in Figure 3.3. The warning message

can be ignored but the errors must be fixed, otherwise the database cannot be

loaded. It is recommended to correct both error and warning before performing

calculation. If you have difficulties loading a particular TDB or PDB file, please

contact CompuTherm, LLC, and we will help resolve the problem.

46

Figure 3.3 A typical message when loading a database

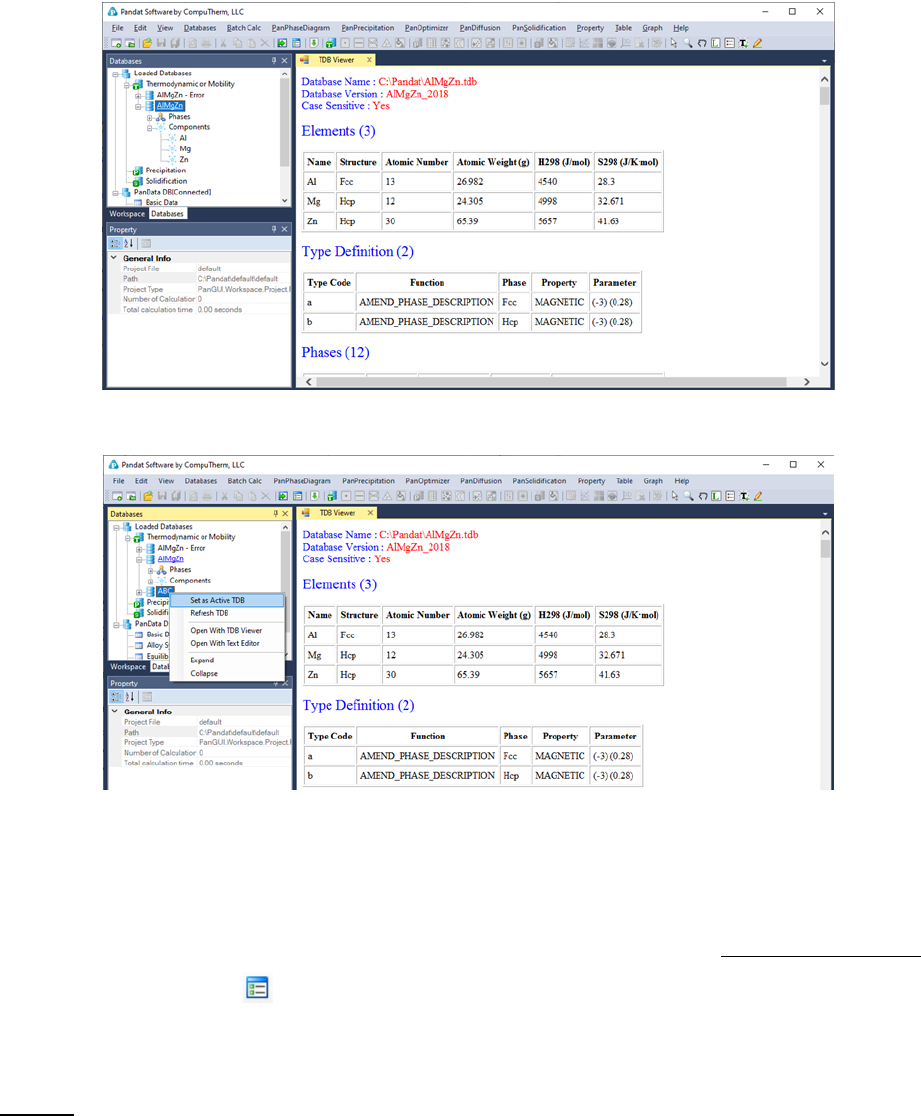

The successfully loaded database will be automatically summarized in the TDB

Viewer mode in the main Display window as shown in Figure 3.4. For a TDB

format database, the summary includes elements, type definitions, phases with

name and thermodynamic model, model parameters and defined functions. For

a PDB format database, the model parameters and functions will not be

displayed. The user can open a TDB format database with the Text Editor mode

by right click of the mouse on the database name in the explorer window. The

Text Editor is actually a built-in notepad for text files. User can use the Text

Editor directly within Pandat

TM

workspace to edit the TDB database, or he/she

can always use his/her favorite text editor to do it.

Multiple databases can be loaded into the same workspace but only one is

activated. The current calculation will use the activated database, which is

highlighted in the explorer window at Database view. The user may set the

inactive database to be active with right click of the mouse as shown in Figure

3.5.

47

Figure 3.4 The TDB viewer mode for database summary

Figure 3.5 Set an inactive database to be active

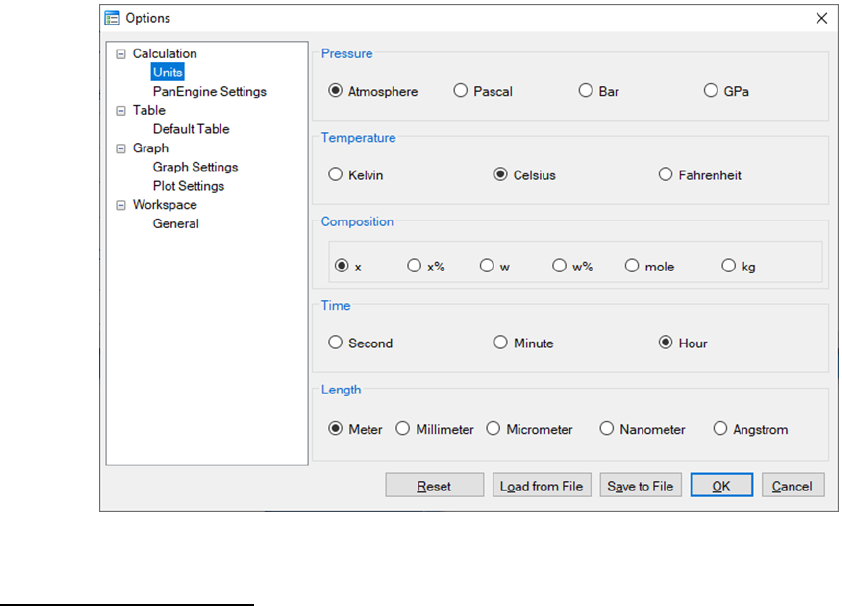

3.2.2 Options

To configure the calculation options, go through the menus (View → Options),

or click on the icon on the toolbar. A pop-up dialog box allows the user to

change the units, and output formats of default Table and Graph.

Units: This dialog box allows the user to choose the units to be used in the

calculation. Use the mouse left button to select a proper unit for each property

and click “OK” to complete the unit setting as shown in Figure 3.6.

48

Figure 3.6 Set units for a calculation in Options

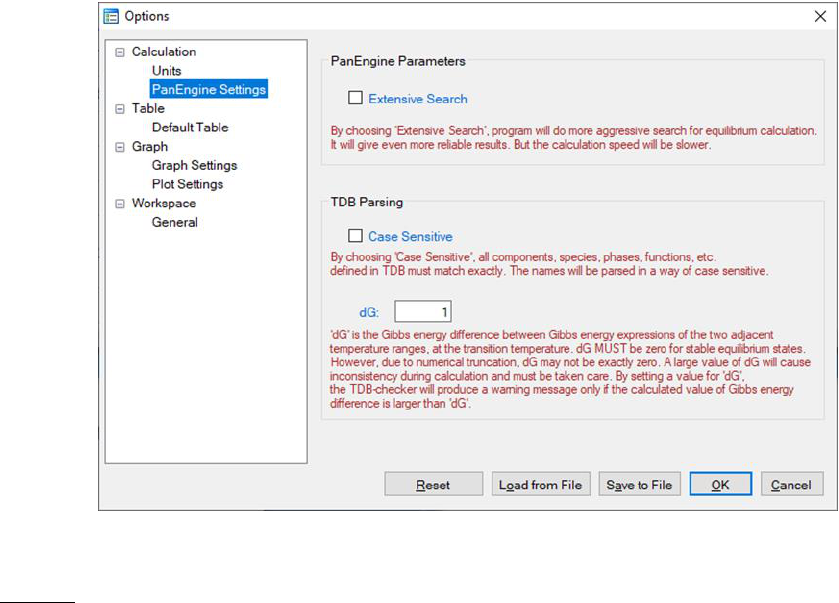

PanEngine Settings: This dialog box allows the user to change the PanEngine

Parameter and TDB Parsing parameters as shown in Figure 3.7. When

“Extensive Search” is checked, PanEngine will perform a more thorough search

of the global equilibrium state in case the Normal Search missed it. For

majority of cases Extensive Search is not necessary and will give the same

answer as that of Normal Search. The calculation will take longer time when

Extensive Search is chosen. Extensive Search is recommended only when the

user found metastable equilibrium in a particular calculation.

If the “Case Sensitive” box is checked, all the components, species, phases,

functions, etc. defined in the TDB will be parsed in a way of case sensitive and

should match exactly, in other words, the uppercase letters are treated as

different from the corresponding lowercase letters.

The Gibbs energy of a pure component with a certain crystal structure is

usually segmental function of temperature and is represented by different

Gibbs energy expression at different temperature range. dG represents the

Gibbs energy difference obtained from the two Gibbs energy expressions at

49

adjacent temperature ranges at the transition temperature. Ideally, dG is zero if

the two Gibbs energy expressions give the exact same value at the transition

temperature. However, due to numerical truncation, dG is usually not zero.

The default setting of dG in PanEngine is 1.0 J/mole atom. A warning message

will be sent to TDB viewer if dG is greater than 1.0. A large dG will cause

calculation fail, therefore should be fixed in the TDB file. User can set this

value to a bigger or smaller value according to his/her tolerance.

Figure 3.7 PanEngine Settings in Options

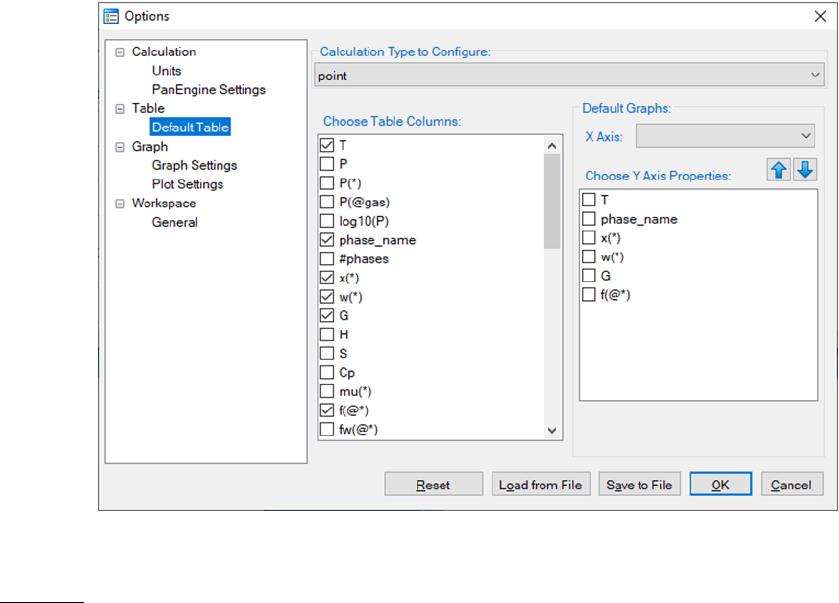

Table: This dialog box allows a user to customize the default output table with

the properties the user needs. As shown in Figure 3.8, user first needs to

choose the “Calculation Type to Configure” which includes point, line, section,

solidification and so on. Once the Calculation Type is selected, all the possible

properties for the chosen Calculation Type will be listed in the “Choose Table

Columns”. The user can check the box in front of each item to select the

column to be shown in the default output table. All the selected properties will

be listed in the “Choose Y Axis Properties”. In this same dialog, user can also

50

define the X axis and Y axis of the default graph that is automatically shown

when a calculation finishes.

Figure 3.8 Set default table output and default dataset for graph output

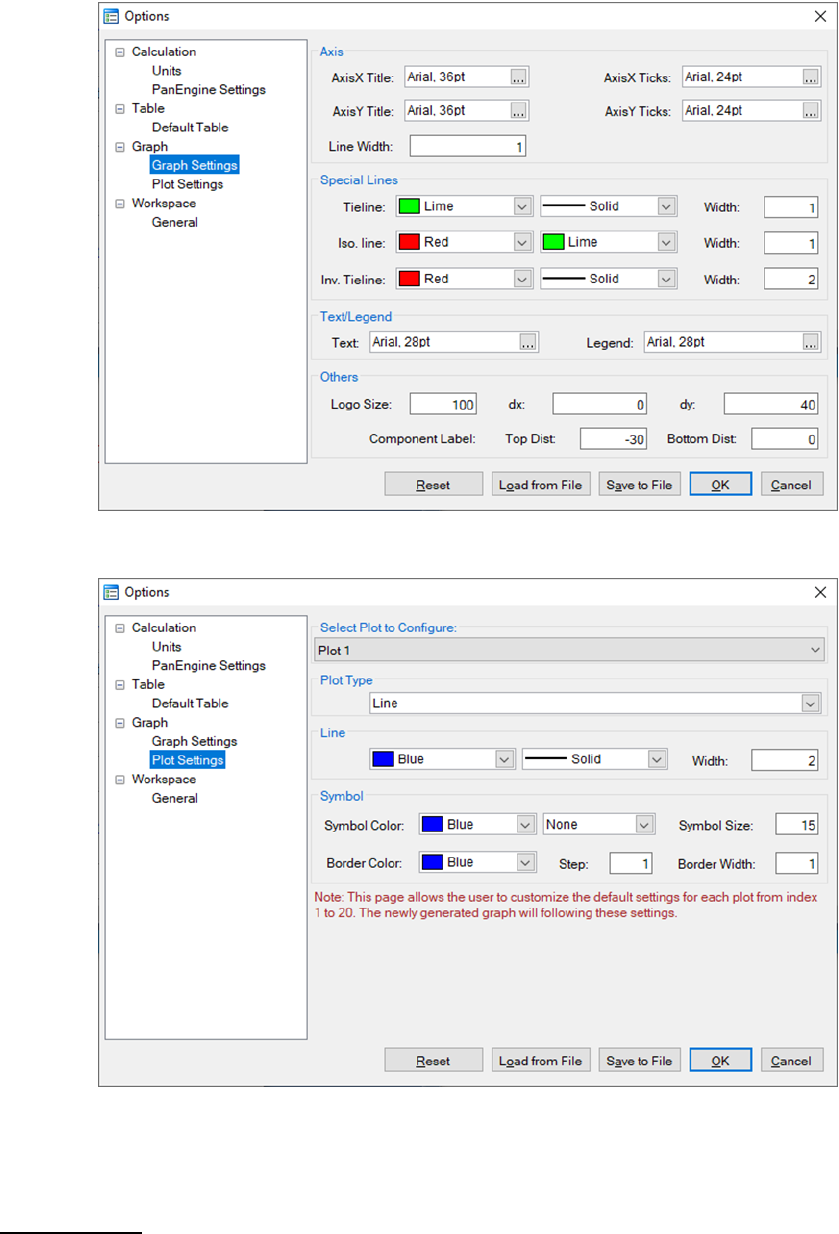

Graph: This dialog box allows the user to set up the appearance of the output

graph. As shown in Figure 3.9, user can set the font and size of the texts, color

and width of the lines, color, shape and size of the symbols, and logo size and

positions for the default graph. User can also set the color and width of the

lines, color, shape and size of the symbols for different plots in one graph as

shown in Figure 3.10.

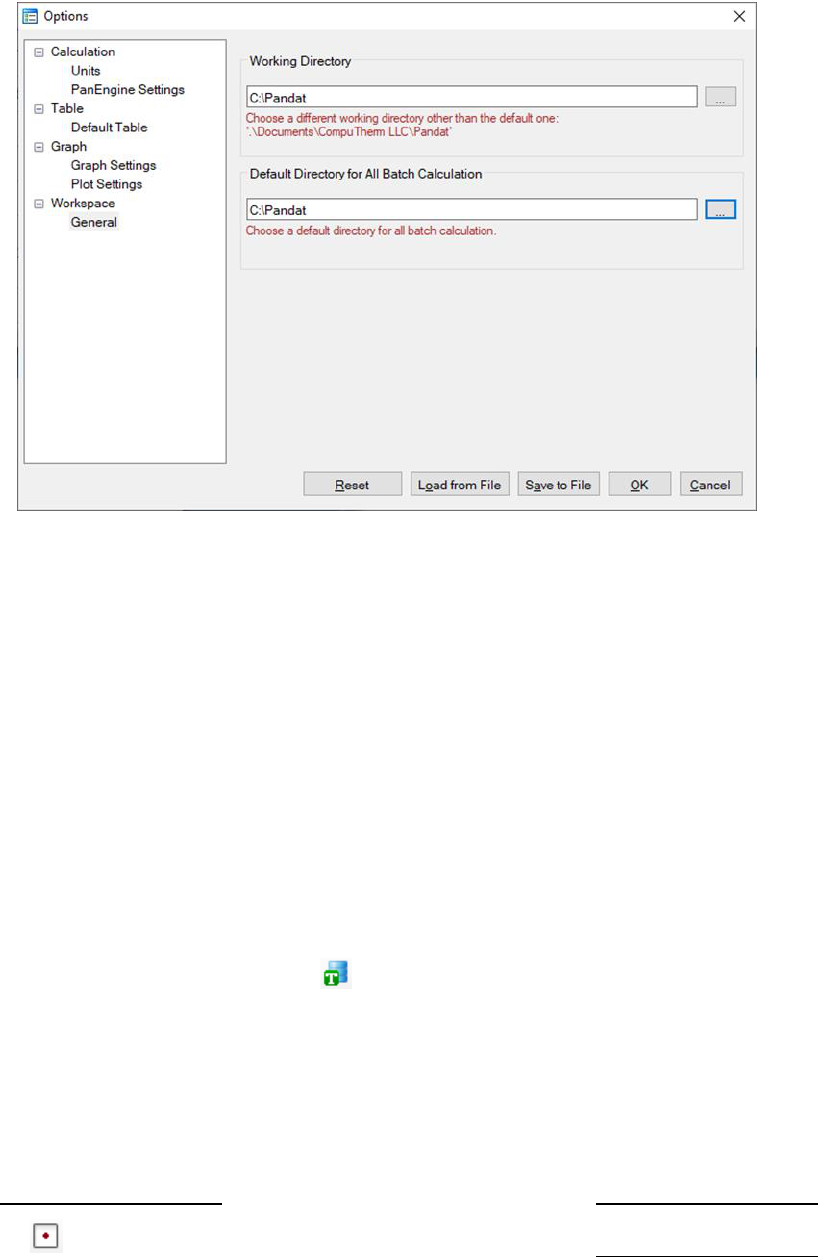

52

Figure 3.11 set up the default working directory for Pandat workspace

It should be pointed out that “Options” gives users the opportunity to change

the PanEngine Setting and customize the output of Default Table and Graph.

However, users do not have to do anything if not necessary. By default, the

most popular setting has been selected for each type of calculation.

3.3 Tutorial

The Al-Mg-Zn is used as an example for the following calculations.

TheAlMgZn.tdb is in the PanPhaseDiagram directory under Pandat

TM

examples.

Load the database by clicking the button and select all three components.

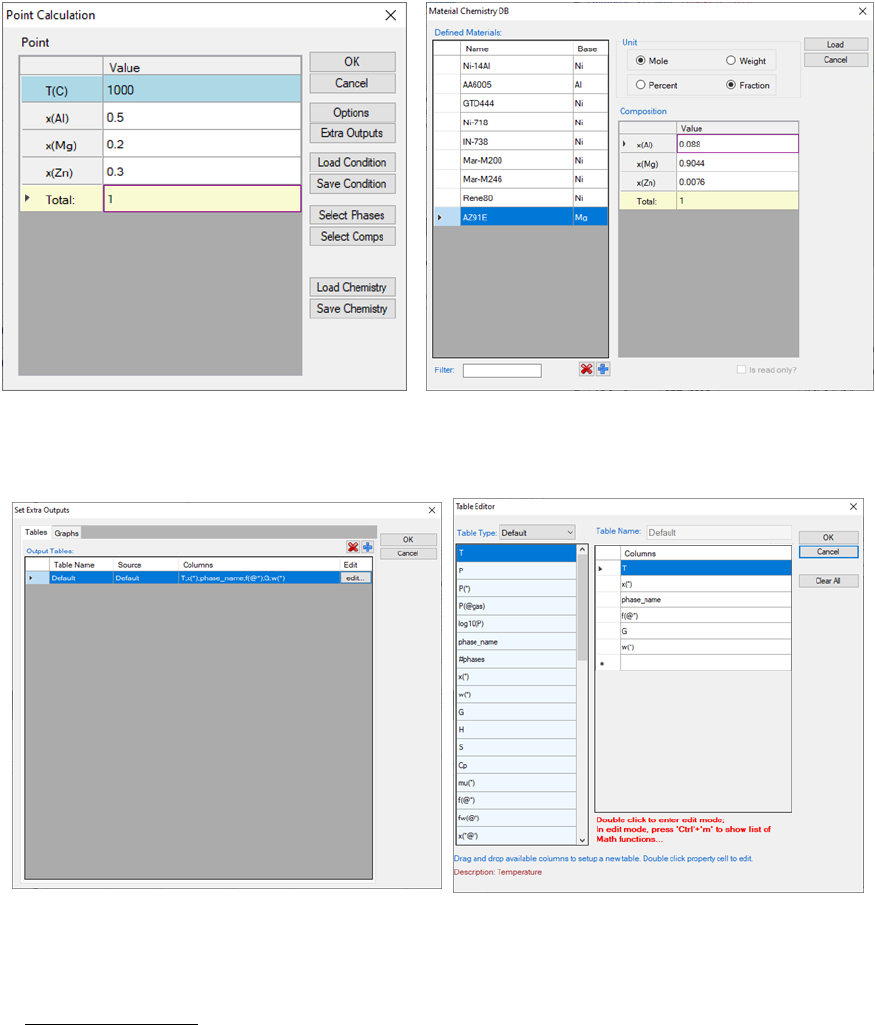

3.3.1 Point Calculation (0D)

This function allows the user to calculate the stable phase equilibrium at a

single point in a multicomponent system.

Go to PanPhaseDiagram on the menu bar and select Point Calculation or

click the button on the tool bar. The dialog box for Point Calculation as

53

shown in Figure 3.12(a) allows the user to set up the calculation conditions:

composition and temperature. User can either input the conditions manually

or use the Load Condition function to load from an existing batch file. User

can always save the current calculation condition to a batch file by clicking the

Save Condition button, or save the alloy composition on hard disc by clicking

Save Chemistry button. User can load the alloy composition for the future

calculation using the function Load Chemistry following Figure 3.12(b).

The functions of other buttons as shown in Figure 3.12(a) are given below. User

can access the Options window again by clicking Options and make changes

for the units. Please refer to the previous section for information on the

Options window. The Extra Outputs button allows the user to modify the

default output table and graph and add more tables and graphs as needed. A

pop out window as shown in Figure 3.13(a) provides the access to the table and

graph for output. User may add or delete output table/graph using the buttons

and , or modify the selected table/graph by clicking the “edit…” button.

Please refer to the previous section for information on Table Edit. The Graph

dialog is slightly different from that described in the previous section. As shown

in Figure 3.13(b), data source for the graph can only be the tables generated

from the calculations and there is a check box for the triangle plot. The

operations for editing the graph are the same as those described in the

previous section.

54

(a) (b)

Figure 3.12 Set alloy composition and Temperature for point calculation

(a) (b)

Figure 3.13 Set extra output table for point calculation

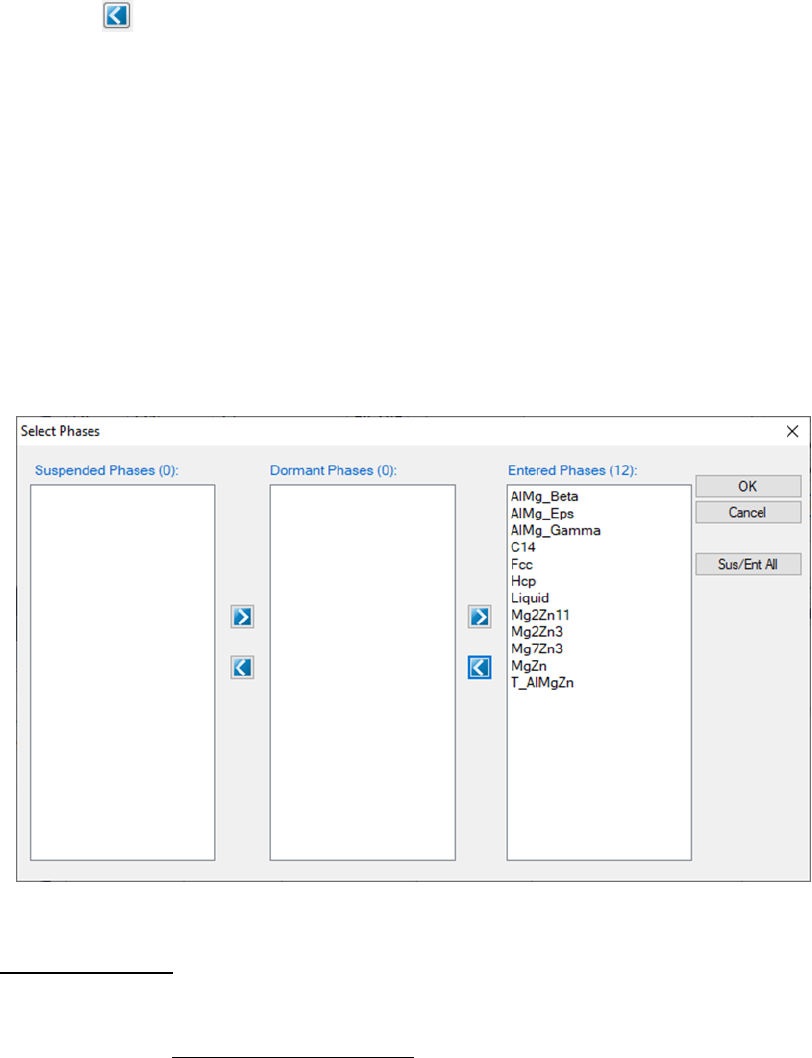

The Select Phases button in Figure 3.12(a) leads the user to a dialog which

allows the user to select or deselect phases to be involved in the calculation as

shown in Figure 3.14. The default setting is that all the phases in the system

are selected and listed in the Entered Phases column, which means all the

phases are involved in the equilibrium calculation. User can select the phases

that will not participate in the equilibrium calculation by sending them to the

Dormant Phases or Suspended Phases column using mouse to drag and drop

55

or using the button. To select several phases at one time, hold the <Ctrl>

key and use mouse to select multiple phases. The Suspended Phases means

that the phases in that column are excluded in any calculations. The Dormant

Phases means that the phases in that column are excluded from the

equilibrium calculation but will be included for the property calculations, such

as driving force, after the equilibrium calculation is finished. The Dormant

Phases option mainly works for point calculation and line calculation. The

Suspended Phases option is usually used for metastable phase equilibrium

calculations.

Figure 3.14 Select Phases dialog

The Select Comps button in Figure 3.12(a) allows user to make last minute

change on the component selection. Please refer to the previous section for

information on the Select Components window.

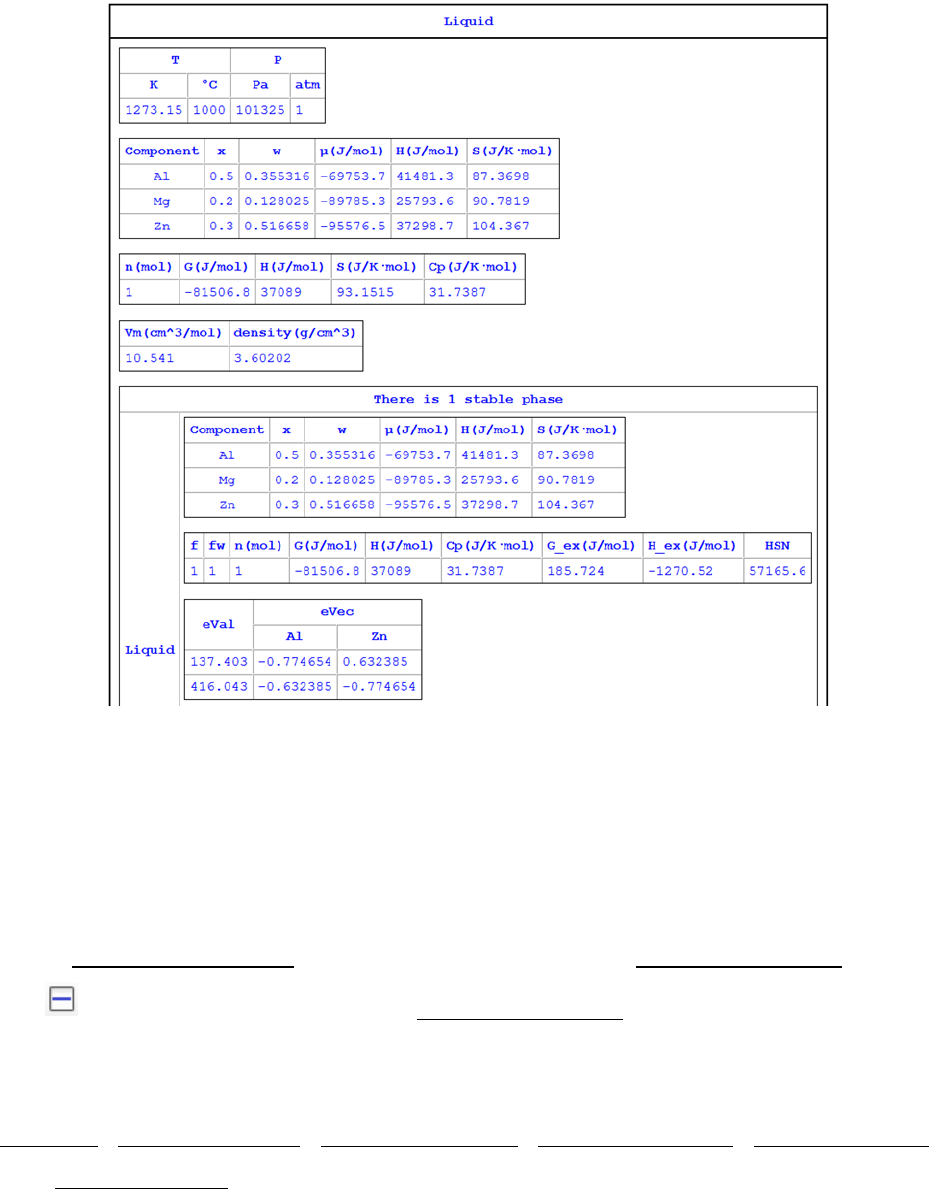

After the calculation is completed, the calculated results are displayed in the

Pandat

TM

main display window as shown in Figure 3.15. The listed properties

include thermodynamic properties at this point, such as Gibbs energy,

enthalpy, entropy and heat capacity. It also lists the stable phases and the

fraction of each phase.

56

Figure 3.15 Results of point calculation

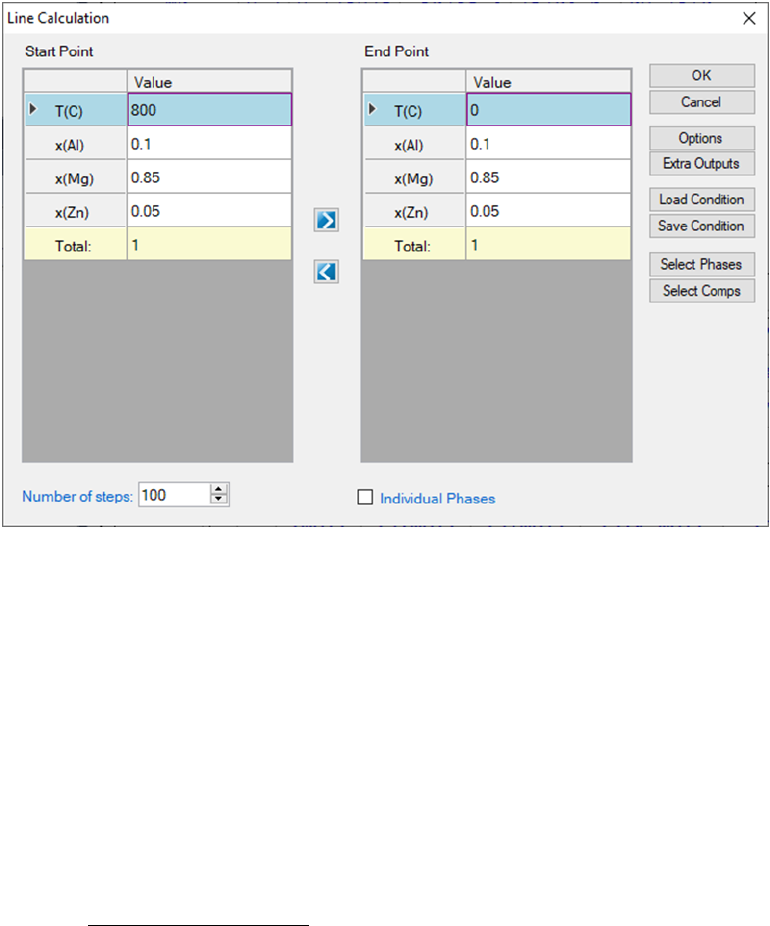

3.3.2 Line Calculation (1D)

This function allows the user to perform a series of point calculations along a

line in a multicomponent system.

Go to PanPhaseDiagram on the menu bar and select Line Calculation or click

the button on the tool bar. The Line Calculation (1D) dialog box allows the

user to set the start and end points of the line, and the number of steps to

calculate along the line as shown in Figure 3.16. User can also access the

Options, Extra Outputs, Load Condition, Save Condition, Select Phases,

and Select Comps the same way as those in point calculation. Note that the

line calculation set up in Figure 3.16 is along the line of fixing alloy chemistry

with varying temperature.

57

Figure 3.16 Set calculation conditions for a line calculation

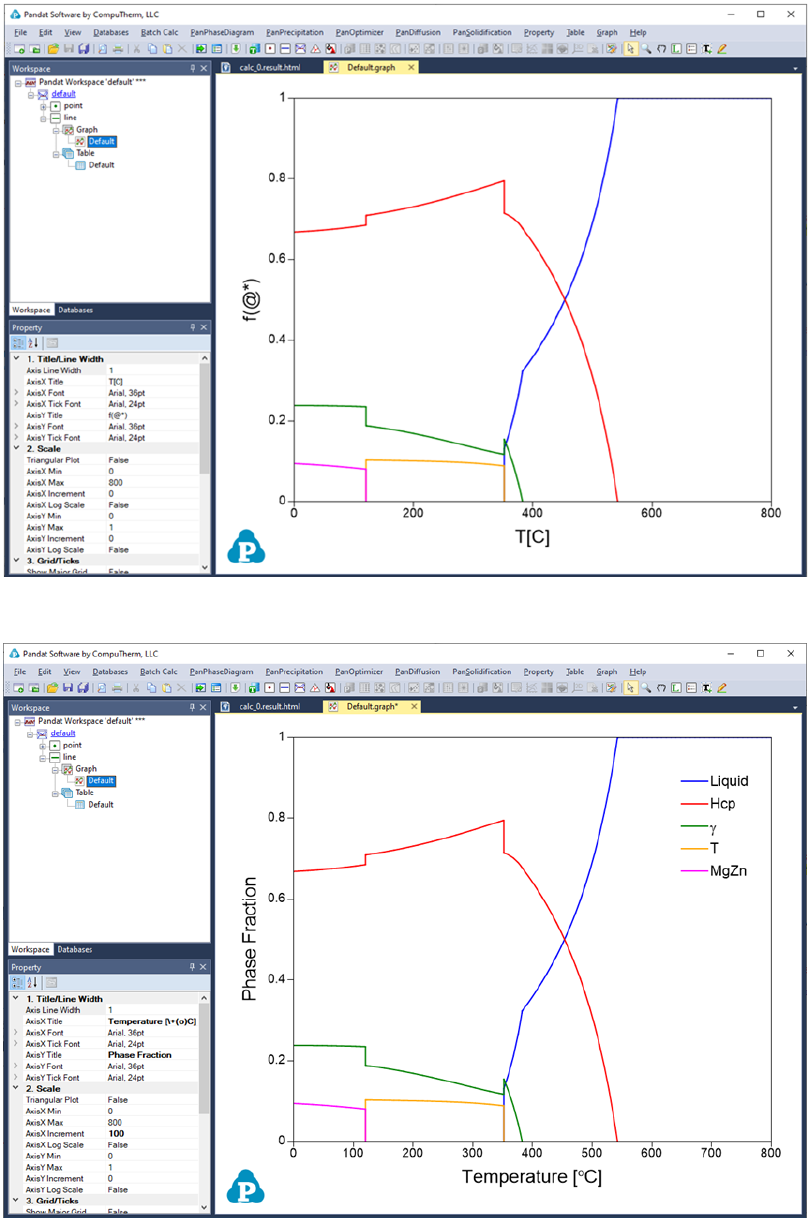

The calculated results are stored in both graph and table. The default graph

plots the variation of fraction of each phase with respect to temperature, as

shown in Figure 3.17. User can modify the graph through the Property window

by modifying the title, scale and add legend to get a better view as shown in

Figure 3.18. In the Explore window, user can double click the “Default” under

the “Table” tree to view the default table. User can select any columns to create

new plots. Furthermore, select the “Table” and right click the mouse, user has

the option to Add a New Table to generate new tables and then plot other

figures as needed.

58

Figure 3.17 Default graph view of the line calculation result

Figure 3.18 Modify the graph with a better view

59

It should be pointed out that user can certainly choose to fix the temperature

and vary the alloy composition for a line calculation.

3.3.3 Section Calculation (2D)

This function allows user to calculate any two-dimensional section of a

multicomponent system. Three non-collinear points in the calculation space

are required to define a 2D section. Common 2D section diagrams are

isotherms and isopleths.

Go to PanPhaseDiagram on the menu bar and select Section Calculation or

click the button on the tool bar. The Section (2D) Calculation dialog box

allows the user to set up the calculation conditions in terms of composition

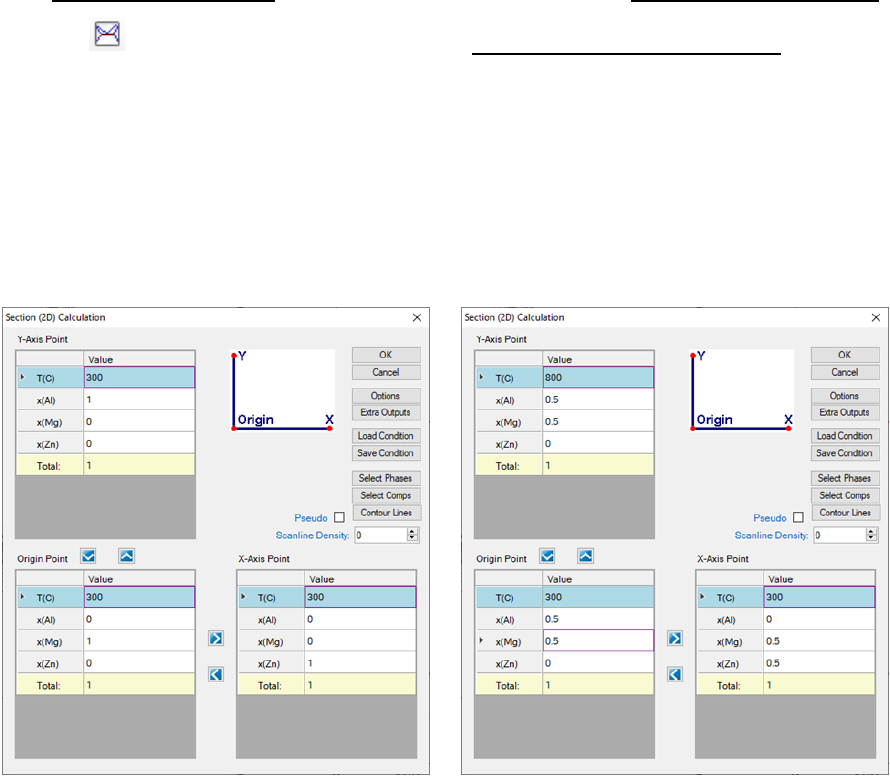

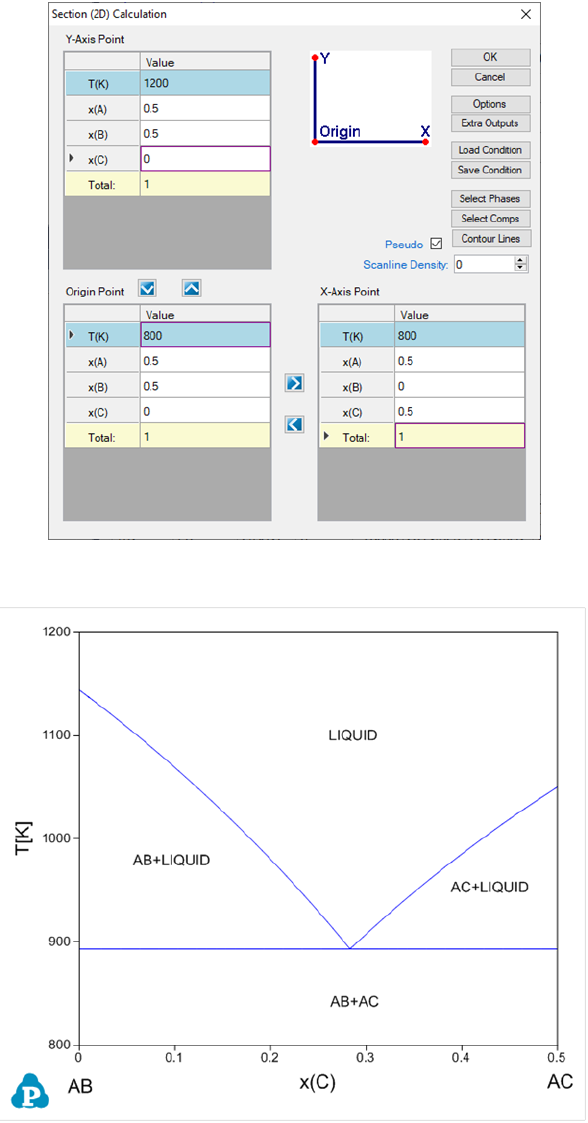

and temperature. Figure 3.19 shows the two most common 2D calculations for

a ternary system: (a) Isotherm which is a horizontal section that fixes the

temperature and (b) Isopleth which is a vertical section that uses the

temperature as the Y axis.

(a) (b)

Figure 3.19 Set calculation conditions for section calculation

60

The composition at each point should be self-consistent. For example,

x(Al)+x(Mg)+x(Zn)=1 for the Al-Mg-Zn ternary system. It is not necessary to have

a correlation between the Y-Axis point, the Origin point and the X-Axis point.

User can also access the Options, Extra Outputs, Load Condition, Save

Condition, Select Phases, and Select Comps windows through this dialog box.

The Contour Lines option allows the user to add special lines to the output

results, such as Tc curve and T

0

curve as shown in Figure 3.20.

Figure 3.20 Contour Lines dialog

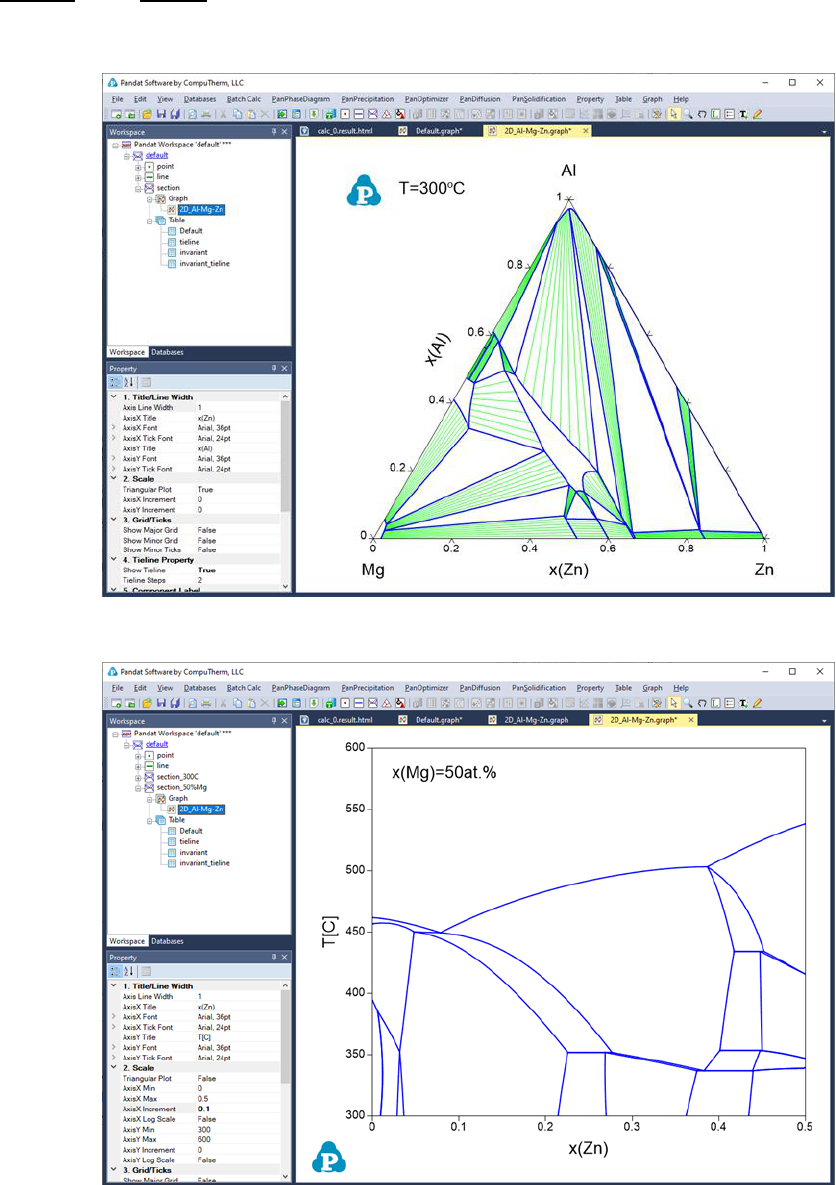

The setting on Figure 3.19(a) defines a calculation of an isothermal section for

the Al-Mg-Zn ternary system at 300

o

C. The setting on Figure 3.19(b) defines a

vertical section calculation from the middle of the Al-Mg binary to the middle of

the Mg-Zn binary in the temperature range of 300-800

o

C. The results from a

Section calculation are displayed in two types of format in the Pandat

TM

main

window: Graph and Table. Figure 3.21 and Figure 3.22 show the graph view of

the calculation results for the settings in Figure 3.19 (a) and (b), respectively.

Figure 3.23 shows a table view of the isotherm calculation result. User can

switch between Graph view and Table View by double clicking on the graph

name or table name in the Pandat

TM

Explore window. Other operations on

61

Graph and Table, such as labeling and adding a legend, have been discussed

in details in Section 2.3 and Section 2.4.

Figure 3.21 Isothermal section of the Al-Mg-Zn ternary system at 300

o

C

Figure 3.22 Isopleth of the Al-Mg-Zn ternary system at 50 at.% of Mg

62

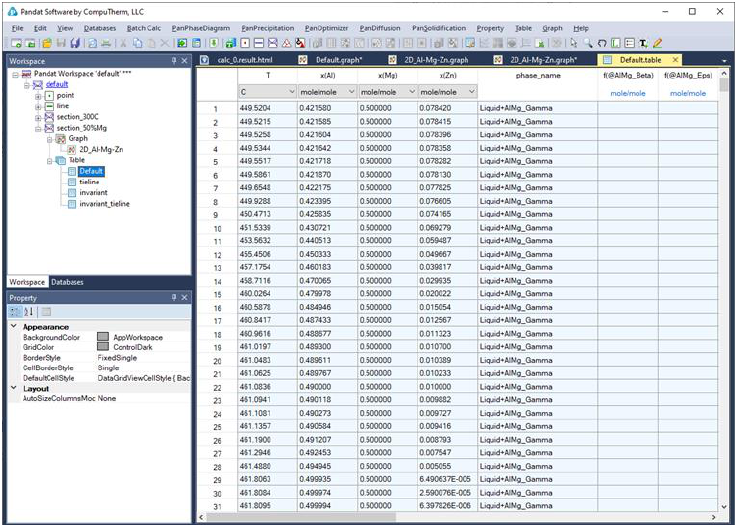

Figure 3.23 Table view for the 300

o

C isotherm calculation results

3.3.4 Pseudo Binary Section

Sometimes a ternary isoplethal section is so special that all the tie-lines are

with this section to form a pseudo binary section. To calculate this type of

section, a special algorithm is designed in Pandat

TM

and a special keyword

“pseudo” is required. In the folder where Pandat

TM

software is installed: Pandat

2020 Examples/PanPhaseDiagram/Pseudo_Binary/, there is an example A-

B-C system with “Pseudo_Binary.tdb”. After load the database file, click on

“Section Calculation”. Set the calculation condition and check the “Pseudo”

box, as shown in Figure 3.24. The calculated pseudo binary section is shown in

Figure 3.25.

63

Figure 3.24 Set calculation condition for a pseudo-binary section

Figure 3.25 A pseudo-binary section in a ternary A-B-C system

64

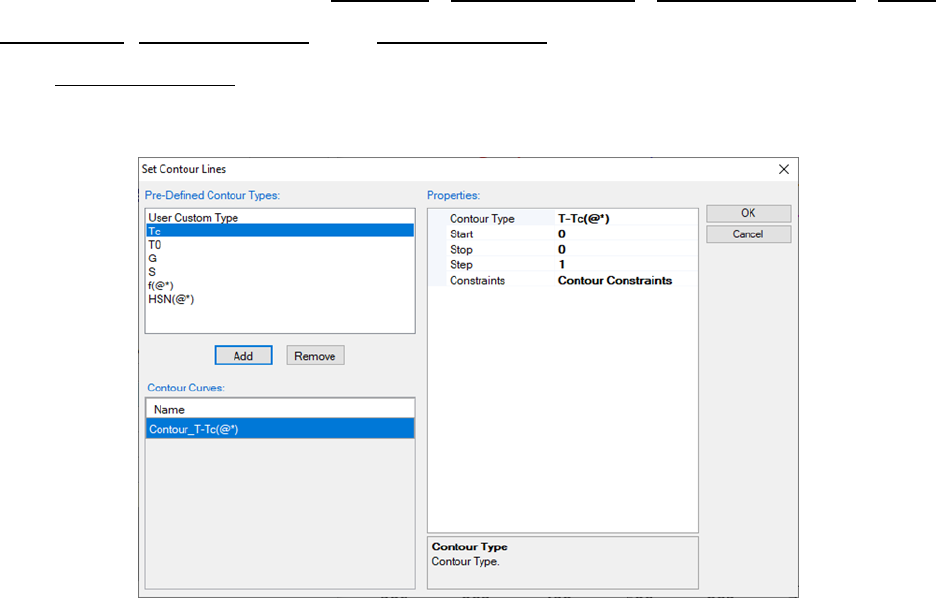

3.3.5 Contour Diagram

Contour diagram shows how a property changes in a 2D or 3D diagram

[2015Che]. The most commonly used contour diagram is the ternary

isothermal lines superimposed on a liquidus projection. Another example is the

activity contour diagram. Pandat

TM

extends contour diagram to many other

properties including thermodynamic properties, physical properties and any

combination of them. In the following, we will give a few examples of useful

contour diagrams. Please keep in mind that Pandat

TM

can plot many other

contour diagrams beyond these examples.

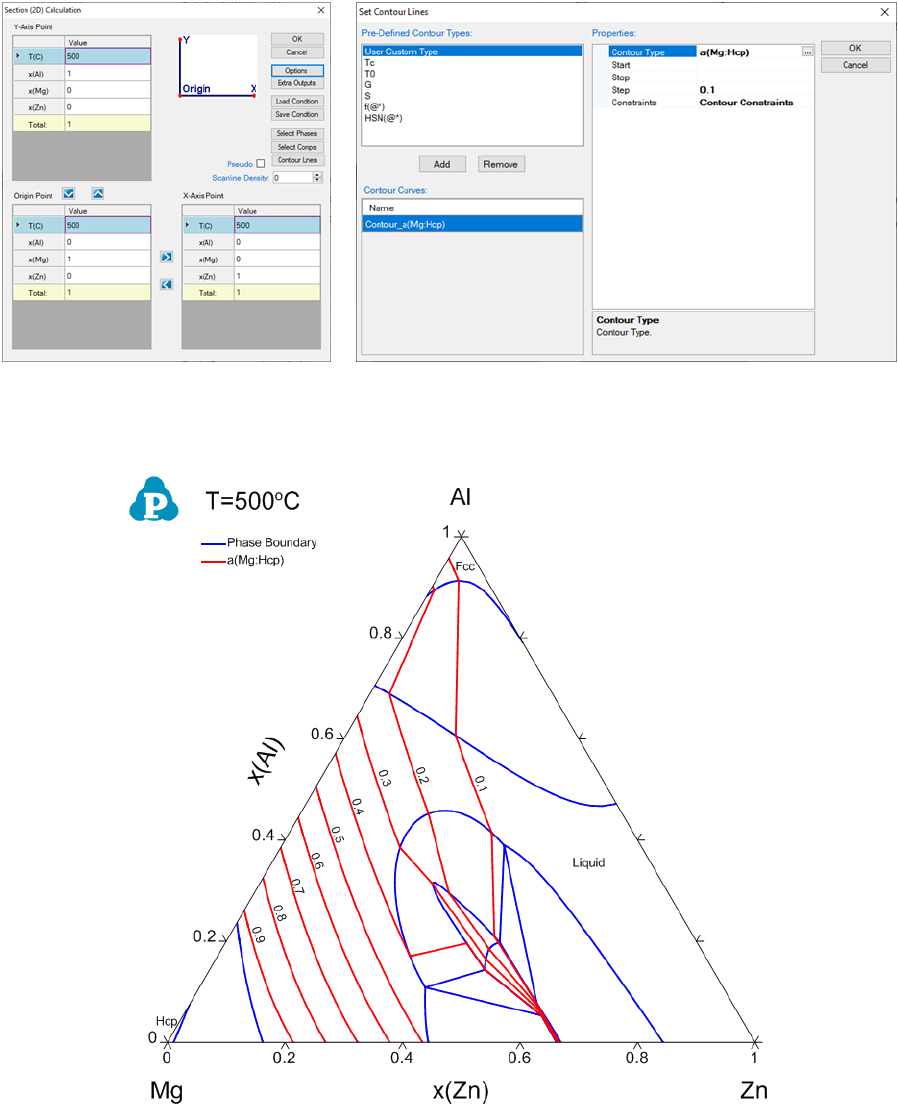

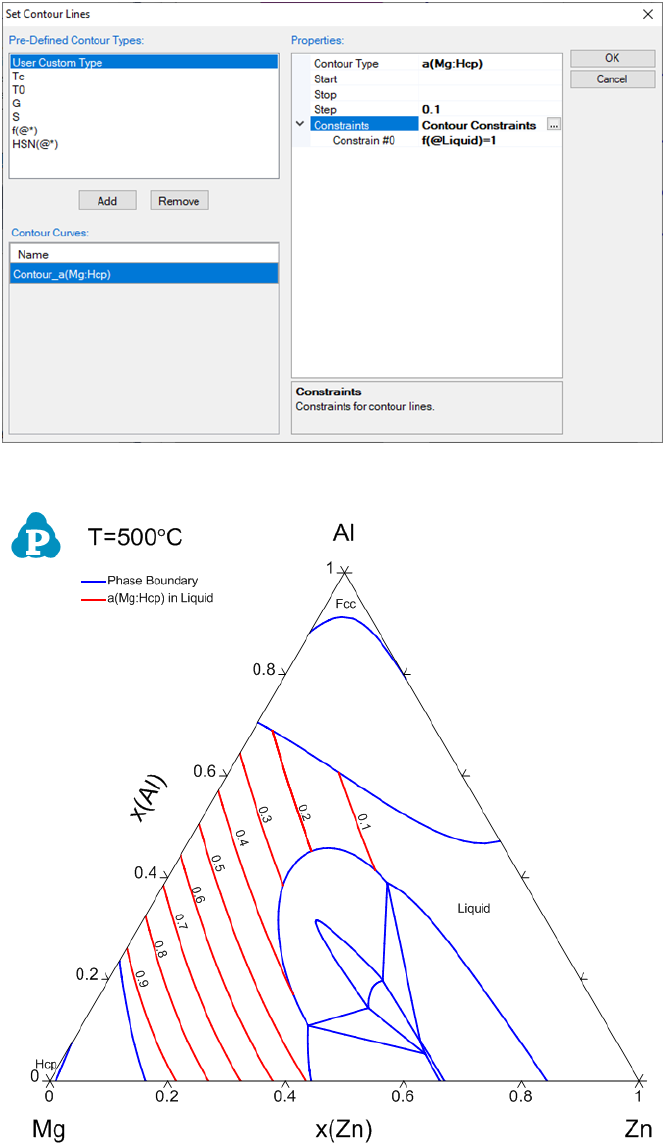

3.3.5.1 Activity Contour Diagram

Let’s use the contour diagram of Mg activity in Al-Mg-Zn as the first example.

Figure 3.26(a) shows the input window for calculating the isothermal section of

Al-Mg-Zn at 500°C. In this input window, there is a button “Contour Lines”.

Click on the “Contour Lines” button, a new window “Set Contour Lines” will

pop out, as shown in Figure 3.26(b). Click on “Add” button and change the

“Contour Type” to “a(Mg:Hcp)”, which means that the contour diagram is for

the activity of Mg with reference state of Hcp. There are three initials related to

which values of the contour lines to be calculated: “Start”, “Stop” and “Step”. In

this example, “Start” and “Stop” can be left as empty and Pandat

TM

will search

for all possible values. User can set values for “Start” and “Stop” for specific

range of the contour lines. However, the value of “Step” must be given. Another

condition “Constraints” will be explained later. Figure 3.26(b) sets the initial

condition to calculate the contour lines for the activity of Mg referring to Mg in

Hcp phase with the step size of 0.1. Click “OK” in this window and also in the

“Section (2D) Calculation” window to proceed the calculation. The calculated

isothermal diagram with the contour lines of activity of Mg is shown in Figure

3.27 after labeling.

65

(a) 2D Diagram input window (b) Contour Diagram input window

Figure 3.26 Input windows for contour diagram of activity of Mg at 500°C

Figure 3.27 Contour diagram of activity of Mg in the isothermal section of Al-

Mg-Zn at 500°C

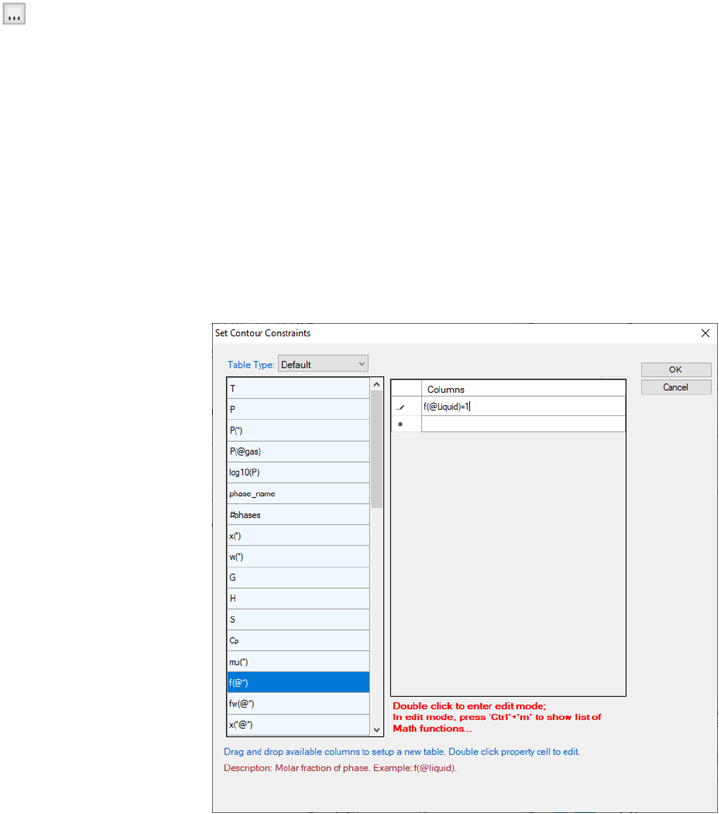

If we want to calculate the contour lines of the Mg activity only in the liquid

phase, it can be achieved by setting a constraint in the contour diagram input

66

condition. In Figure 3.26(b), click on “Contour Constraints”, a small button

will show up. Click on it, we will have a window of “Set Contour

Constraints” as shown in Figure 3.29. Add “f(@Liquid)=1” as the constraint

in this window and then click “OK” to return to “Set Contour Lines” window

as in Figure 3.29. This will set a constraint on the contour line calculation that

only the contour lines with “f(@Liquid)=1” will be calculated. Figure 3.30 is

the calculated phase diagram with the contour diagram of a(Mg) only in the

liquid phase region in the isothermal section of Al-Mg-Zn at 500°C.

Figure 3.28 Set contour constraints window

67

Figure 3.29 Input windows for setting constraints for the contour diagram

Figure 3.30 Contour diagram of activity of Mg only in liquid phase in the

isothermal section of Al-Mg-Zn at 500°C

68

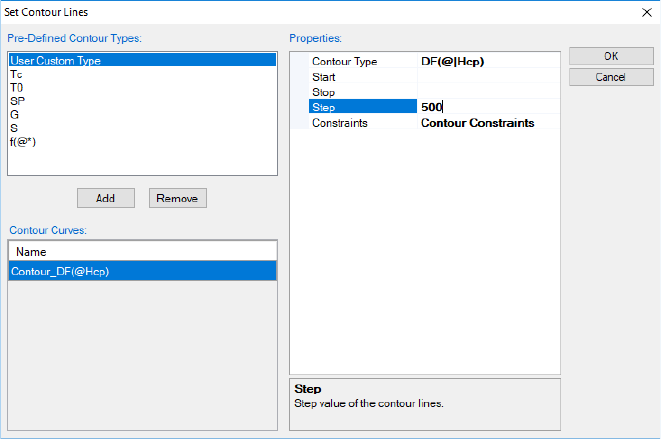

3.3.5.2 Driving Force Contour Diagram

Contour diagram is also useful in viewing the stability of a phase comparing to

the equilibrium state. Figure 3.31 shows the driving force contour lines of the

Hcp phase in the Al-Mg-Zn system at 500°C. The contour type is defined as

DF(@|Hcp)as shown in Figure 3.31 (see Table 2.2 for the definition of DF).

Since Hcp phase may not be stable in all the phase regions in this isothermal

section, in between “@” and “Hcp” a vertical bar symbol “|” is added to specify

that the phase Hcp is in the “entered” status. From Figure 3.32, we see that

Hcp phase has less driving force to be stable in the central region of the

compositional triangle.

Figure 3.31 Set driving force contour

69

Figure 3.32 Contour diagram of the driving force of the Hcp phase relative to

the equilibrium phases in Al-Mg-Zn at 500°C

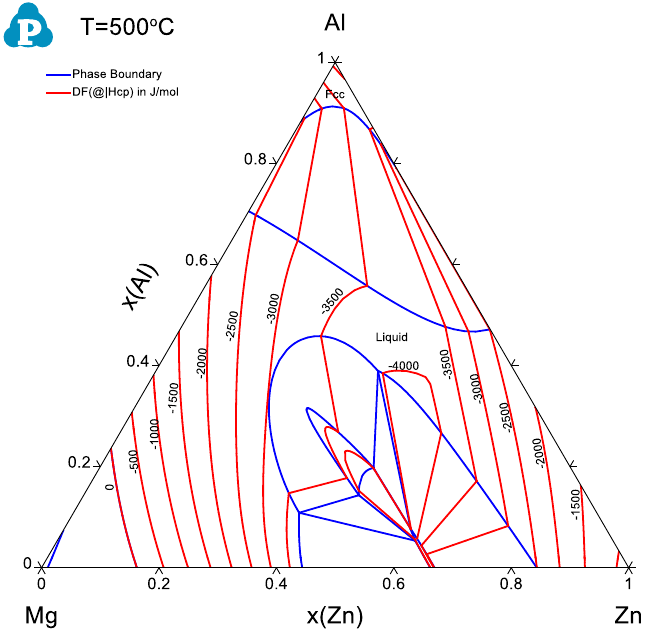

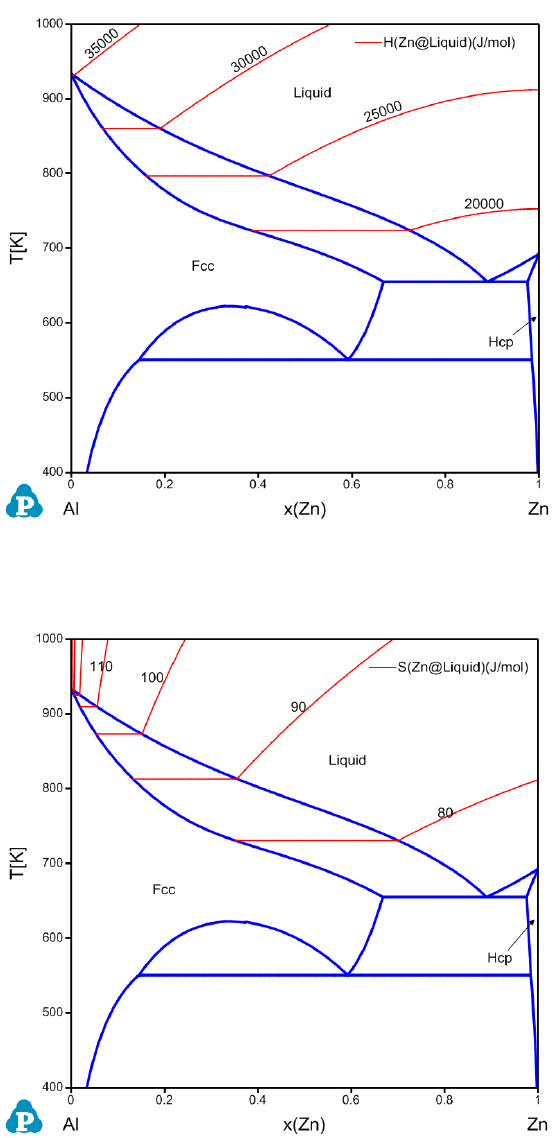

3.3.5.3 Partial Molar Property Diagram

Partial molar properties such as partial molar enthalpy and entropy of a

component can also be calculated as a contour diagram along with the phase

diagram. The red curves in Figure 3.33 and Figure 3.34 are the calculated

contour curves of the partial molar enthalpy and entropy of Zn in the liquid

phase for the Al-Zn system. The constraints in both calculations are

f(@Liuid)>0 since the calculation is for the stable liquid phase only.

70

Figure 3.33 Contour diagram of the partial molar enthalpy of Zn in the liquid

phase of Al-Zn system.

Figure 3.34 Contour diagram of the partial molar entropy of Zn in the liquid

phase of Al-Zn system.

71

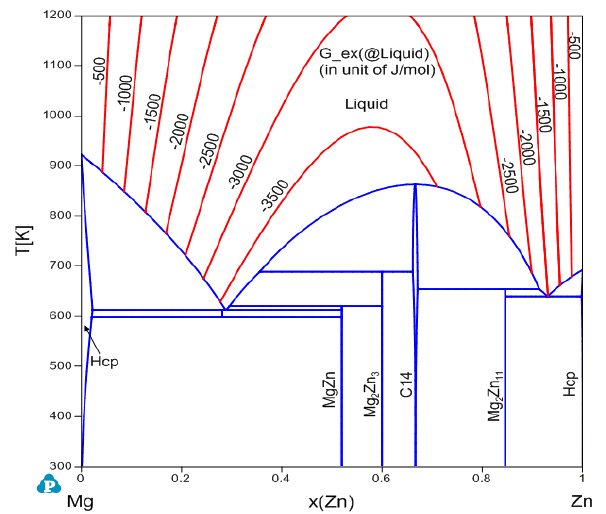

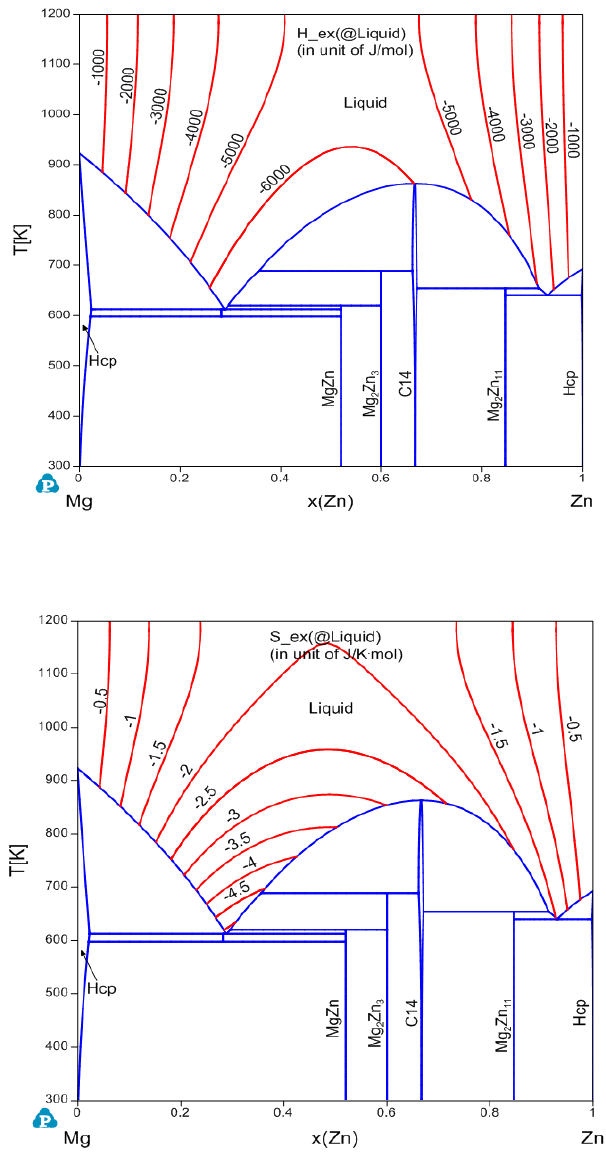

3.3.5.4 Excess Molar Property Diagram

Sometimes we have interest in the excess properties, such as excess Gibbs free

energy, excess enthalpy and excess entropy of a phase. These properties are

available from the property definitions of G_ex, H_ex and S_ex in a contour

diagram. Figure 3.35, Figure 3.36 and Figure 3.37 show the calculated contour

curves for the excess properties of liquid in the Mg-Zn system.

Figure 3.35 Contour diagram of the excess Gibbs free energy in the liquid

phase of Mg-Zn system.

72

Figure 3.36 Contour diagram of the excess enthalpy in the liquid phase of Mg-

Zn system.

Figure 3.37 Contour diagram of the excess entropy in the liquid phase of Mg-

Zn system.

73

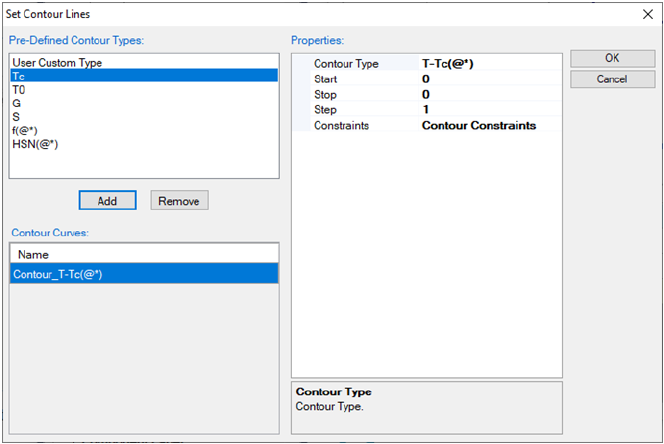

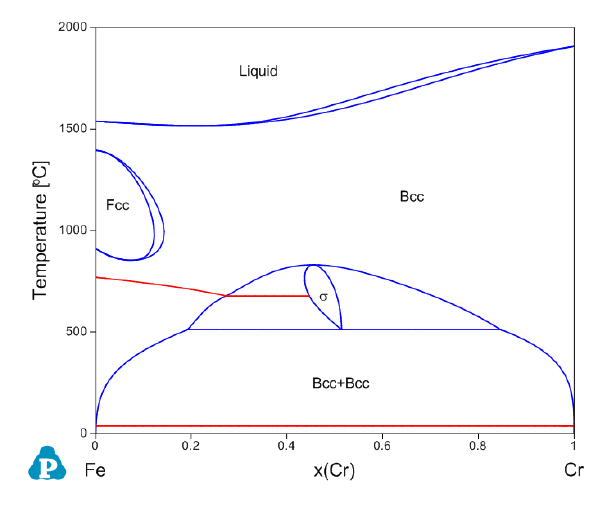

3.3.5.5 User Defined Contour Diagram

Contour diagram can be any type of customized properties defined by the user

using a mathematical expression. Contour diagram can therefore be used to

plot some special property lines. For example, we want to calculate Curie

temperature Tc curves in the Fe-Cr system. A Tc curve can be considered as a

special contour line when T equals to Tc, which means the constraint: T-Tc=0

is set on the Tc curve. Figure 3.38 is the input window for calculating the Tc

contour curves. Since the constraint is T-Tc(@*)=0, the “Start” and “Stop”

values are both set to be zero, and “Step” value is ignored. @* means in every

phase. Figure 3.39 is the calculated Fe-Cr phase diagram with the Tc curves of

the Bcc phase.

Figure 3.38 Input windows for Tc curves in Fe-Cr system

74

Figure 3.39 Phase diagram of Fe-Cr with Curie temperature curves (in red

color) of Bcc phase

A second order transition curve could also be calculated as a contour curve.

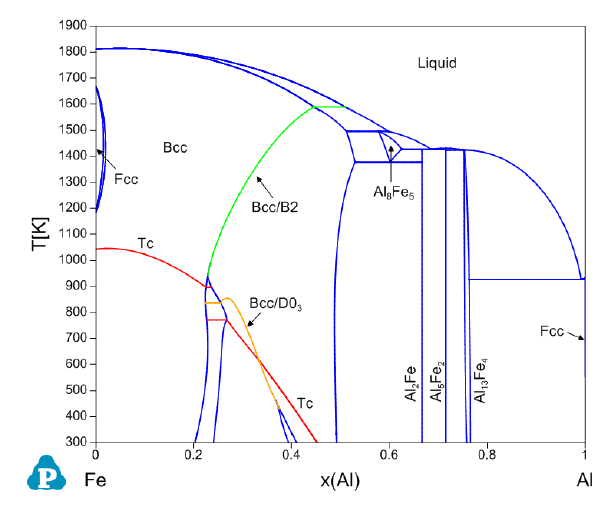

Fe-Al binary system [2009Sun] is given as an example here. Figure 3.40 is the

calculated Fe-Al binary phase diagram with Tc curves and the second order

transition curves. The Tc curves can be calculated the same way as that shown

in this section for the Fe-Cr system.

The calculation of the second order transition needs special contour property

definition. For the Bcc/B2, the contour property is defined as

abs(y(Fe#2@BCC_4SL)-y(Fe#3@BCC_4SL))

which represents the absolute value of the difference between the site fractions

of Fe on the 2

nd

and 3

rd

sublattices. The “start” and “stop” values are set to

be “0.05”, which avoids the numerical difficulty in calculation and gives a very

good approximation of the order/disorder transition curves.

75

Figure 3.40 Phase Diagram of Fe-Al with the Tc curves and the 2

nd

order

transition curves between Bcc and B2 and between B2 and D0

3

.

The contour property for the second order transition between B2 and D0

3

is

defined as

abs(y(Fe#3@BCC_4SL)-y(Fe#4@BCC_4SL))

with the “start” and “stop” values of “0.05”. A constraint is also added in this

contour calculation to make sure that the first and second sublattices have the

same site fractions,

abs(y(Fe#1@BCC_4SL)-y(Fe#2@BCC_4SL))<0.001

Pandat

TM

batch file is written in the language of XML(Extensible Markup

Language). The less-than “<” and great-than “>” characters are reserved as the

XML special characters. In an XML file, the less-than “<” and great-than “>”

symbols are written as “<” and “>”. Above constraint is written in a

Pandat batch file as

abs(y(Fe#1@BCC_4SL)-y(Fe#2@BCC_4SL))<0.001

76

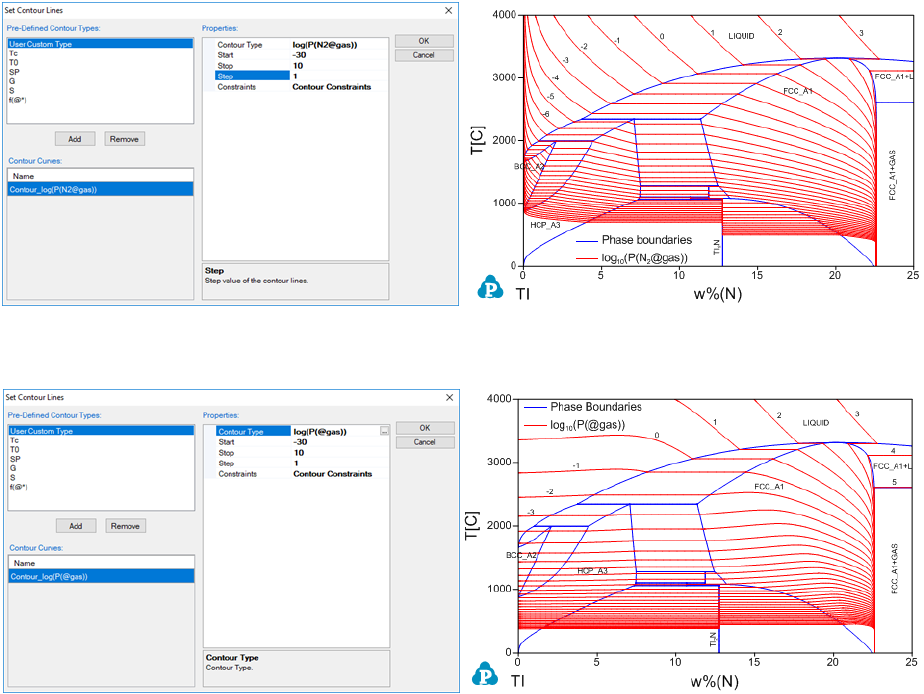

3.3.5.6 Partial Pressure Contour Diagram

The following example shows how to calculate the contour lines for the partial

pressure of the gas phase in the Ti-N system [1996Zen]. Figure 3.41 (a) is the

input condition window and Figure 3.41 (b) is the calculated phase diagram of

Ti-N with the contour lines of log(P(N

2

@gas)) (pressure unit is Pa), which is the

common logarithm of the partial pressure of N

2

in gas. Figure 3.41 (c) is

another input condition window and Figure 3.41 (d) is the calculated phase

diagram of Ti-N with the contour lines of log(P(@gas)), which is the common

logarithm of the total pressure of gas with the gas species N, N

2

, N

3

and Ti.

(a) Input condition (b) log(P(N

2

@gas)) contour

(c) Input condition (d) (log(P(@gas)) contour

Figure 3.41 Contour diagrams of partial pressure of gas in the Ti-N system

More examples can be found in the Pandat example folder:

/PanPhaseDiagram/Contour/.

77

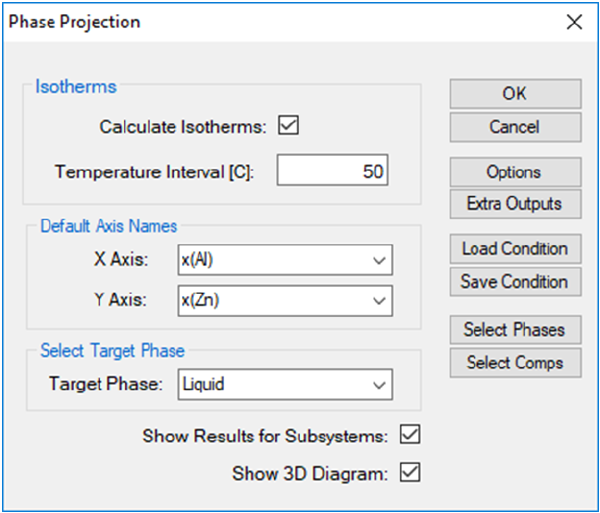

3.3.6 Phase Projection

This function permits the calculation of a phase projection diagram for a

system with two or more components. PanEngine automatically searches the

univariant phase projection lines.

Go to PanPhaseDiagram on the menu bar and select Phase Projection or

Click the button on the tool bar. The Phase Projection dialog box shown in

Figure 3.42 allows the user to calculate projection of any phase in the system.

If “Liquid” is selected as Target Phase, liquidus projection for the system is

calculated. Isothermal curves involving the selected phase in a ternary system

can also be calculated by checking the box Calculate Isotherms. The density

of isothermal curves depends on the scale of Temperature Interval. A larger

value for the temperature interval leads to fewer isothermal curves but with

faster speed of calculation. The default Compositional Range is full range for

each component. User can define the default output graph by selecting the X

and Y axis. User can also access the Options, Extra Outputs, Load Condition,

Save Condition, Select Phases, and Select Comps windows through this

dialog box. If the Show Results for Subsystems box is checked, the output

files will include the results for the subsystems together with the

multicomponent system. Be aware that the output table will be huge if the box

is checked for a calculation with a higher order multi-component system. User

can choose the specific phase for projection calculation in the Target Phase

dialog, such as Fcc phase. If “*” is selected, the projection for all the phases will

be calculated. If the Show 3D Diagram box is checked, there will be an extra

3D diagram showing the calculation results as well as the original 2D diagram.

For the 3D diagram, user can rotate the diagram by holding the left button of

mouse and move it around.

78

Figure 3.42 Phase projection calculation setting dialog

The results from a liquidus projection calculation are displayed in two types of

format in the Pandat

TM

main window: Graph and Table. Figure 3.43 to Figure

3.46 show the 2D and 3D graph view, default table and isotherm table for the

liquidus projection calculation results, respectively. Users can switch between

Graph view to Table View by double clicking on the graph name or the table

name in the Pandat

TM

Workspace window. Extensive operations on Graph and

Table, such as labeling and adding legend, have been discussed in details in

Section 2.3 and Section 2.4.

79

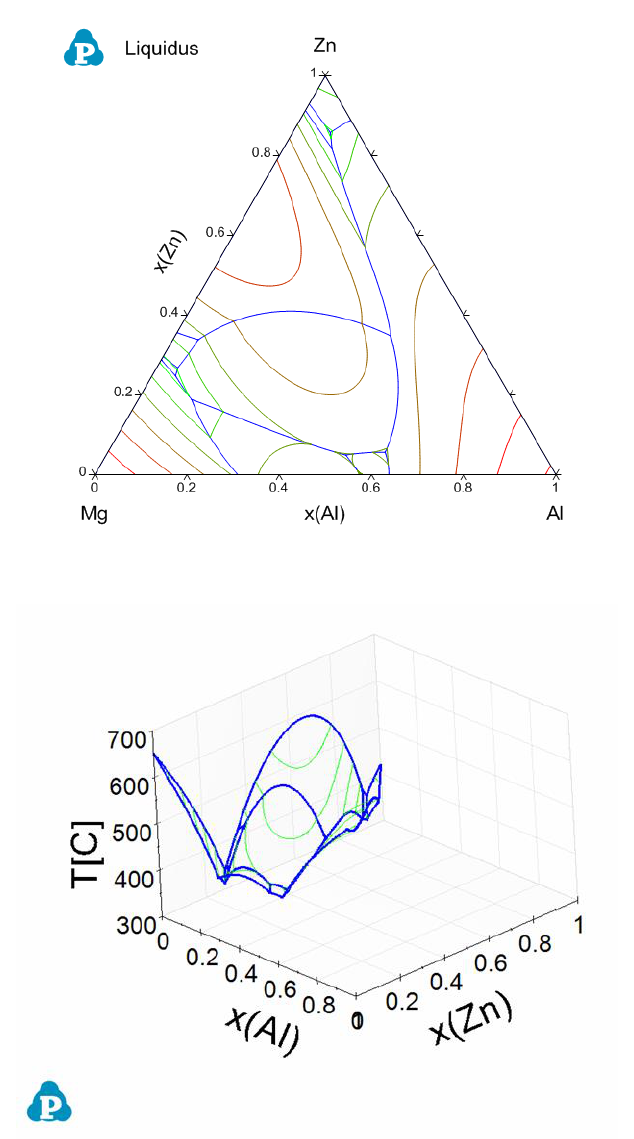

Figure 3.43 Liquidus projection in 2D of the Al-Mg-Zn ternary system

Figure 3.44 Liquidus projection in 3D of the Al-Mg-Zn ternary system

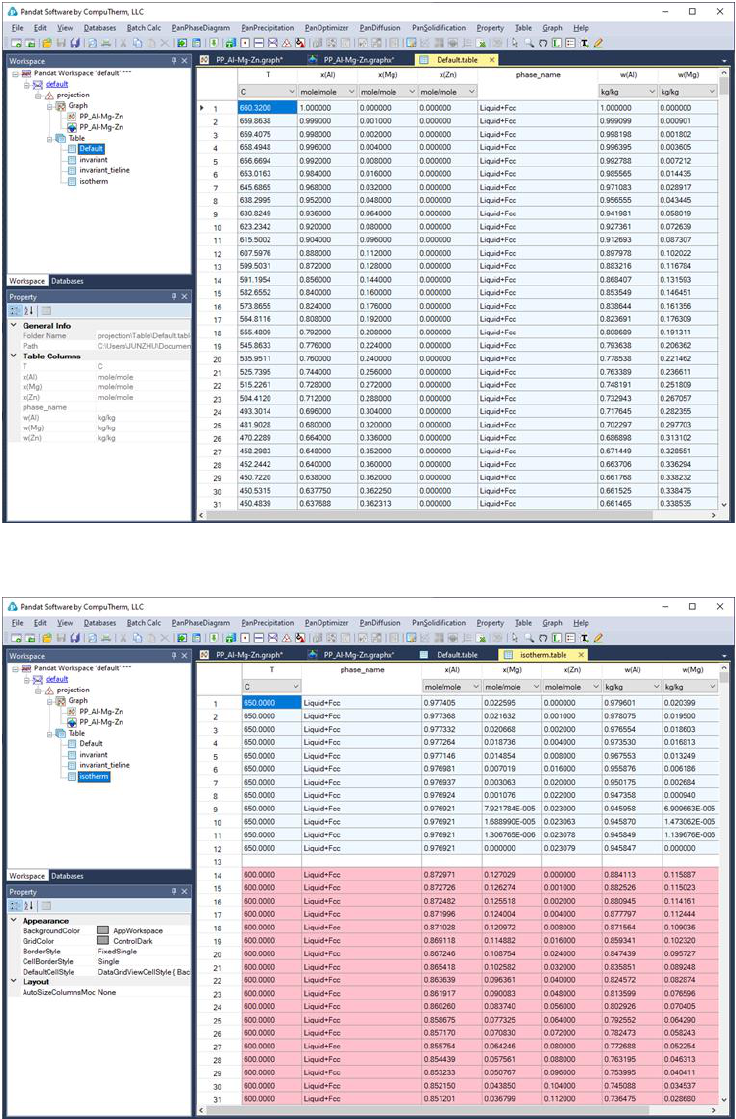

80

Figure 3.45 Default table view for the liquidus projection calculation results

Figure 3.46 Isotherms table for the liquidus projection calculation results

81

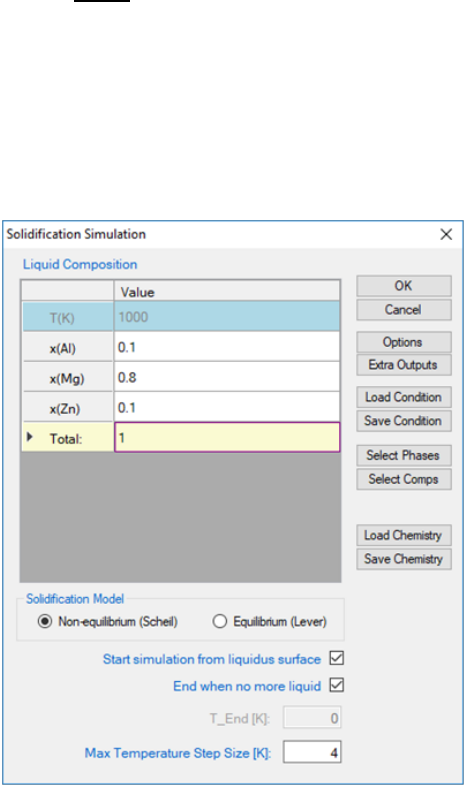

3.3.7 Solidification Simulation

Two simple models, equilibrium solidification and Scheil solidification, have

been integrated into Pandat

TM

for calculating solidification pathways. The

equilibrium model, also called the lever rule model, assumes that complete

diffusion occurs in both liquid and solid phases, and the compositions of solid

and liquid always follow the phase boundaries defined by the equilibrium

phase diagram. The fractions of liquid and solid can be calculated through the

lever rule. In contrast, Scheil solidification assumes that no diffusion occurs in

the solid phases, that the composition of liquid phase is uniform (infinite

diffusivity in liquid) and that local equilibrium at the solid-liquid interface is

always maintained. The Solidification Simulation function calculates the

solidification path of an alloy using either the lever rule or Scheil model as

being decided by the user.

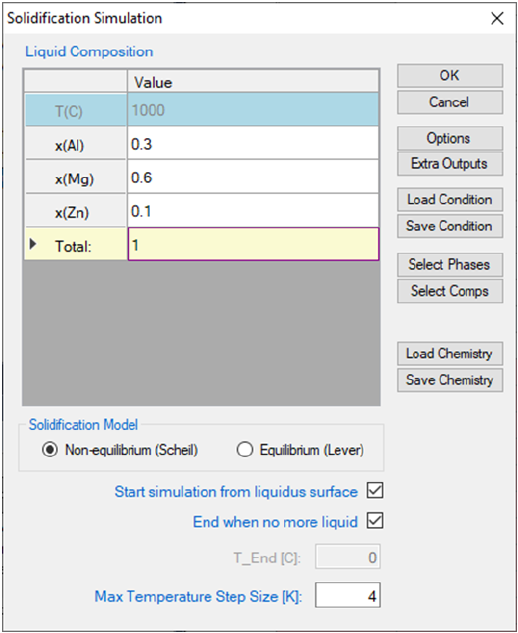

Go to PanPhaseDiagram on the menu bar and select Solidification

Simulation or click the button on the tool bar. The dialog box as shown in

Figure 3.47 allows the user to set up the alloy composition for the solidification

simulation. User can choose the simulation under either Non-

Equilibrium(Scheil) or Equilibrium (Lever Rule) condition. There are two

check boxes at the bottom of the input dialog: Start simulation from liquidus

surface, and End when no more liquid. If both boxes were checked, the

solidification simulation will be carried out in the temperature range when

solid start to form from liquid (liquidus surface) to the point when liquid just

completely disappear. Pandat

TM

software will find these two points

automatically. If one or both of the check boxes are not checked, user will need

to define the start or/and the end temperature for the solidification simulation

proceeds.

82

Figure 3.47 Set calculation conditions for solidification simulation

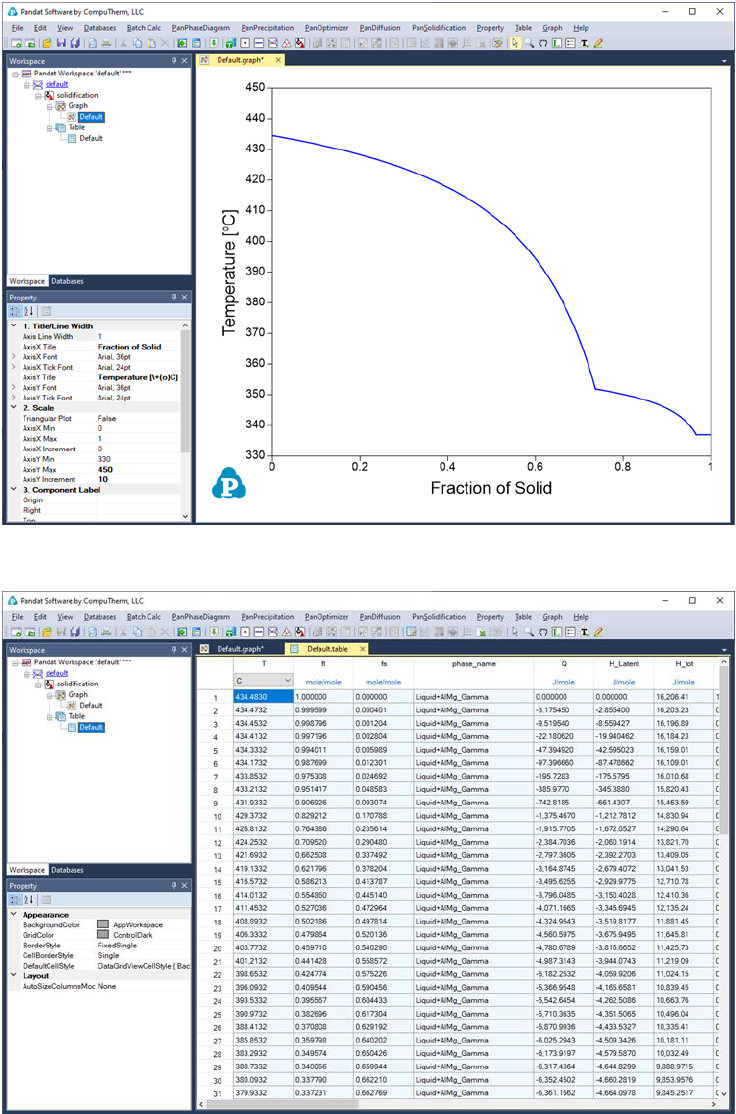

The results are displayed in either Graph View or Table View. Figure 3.48 and

Figure 3.49 show the graph view and table view for the solidification simulation

results with the calculation condition shown in Figure 3.47. Extensive

operations on Graph and Table, such as labeling and adding legend, have been

discussed in details in Section 2.3 and Section 2.4.

PanSolidification, a new module introduced in Pandat 2020, is considered the

back diffusion in the solid phase during solidification. Detailed description on

PanSolidification module is in section 7.

83

Figure 3.48 Graph view of the solidification simulation result

Figure 3.49 Table view of the solidification simulation result

3.3.8 Table Column Functions

Examples are given in this section show how to use the table column property

names and functions to obtain more information from the calculated results.

84

3.3.8.1 Activity and activity coefficient

The activity of a component j,

, is defined by

where

is the chemical potential of the component j in equilibrium state and

is the chemical potential of this component at its reference state. For

example, the activity of component Al in the liquid Al-Mg system referring the

Al in Fcc phase is calculated by

The corresponding Table column name is a(Al@Liquid:Fcc[Al]), or

a(Al@Liquid:Fcc).

If a reference state is not specified in Table column name, the default reference

state in the database is taken as the reference state. For example,

a(Al@Liquid) is calculated by

Activity coefficient is defined as

which is available from Table by defining Table column name similar to that of

activity. Table column name for the activity coefficient of Al in liquid is

r(Al@Liquid:Fcc[Al]), or r(Al@Liquid:Fcc).

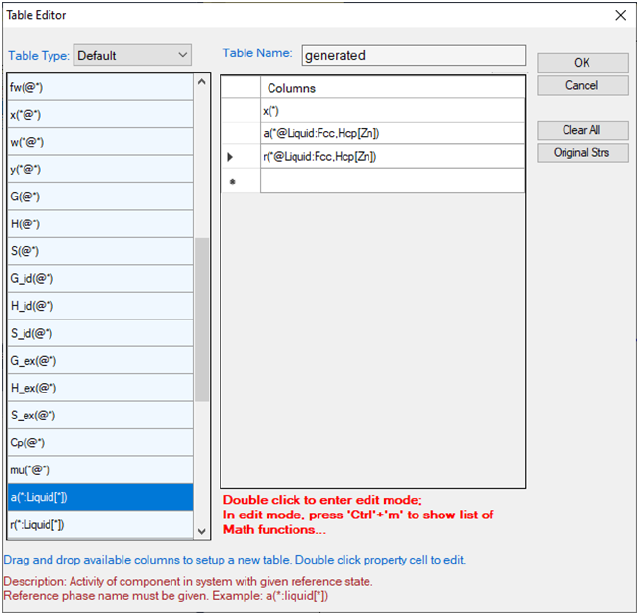

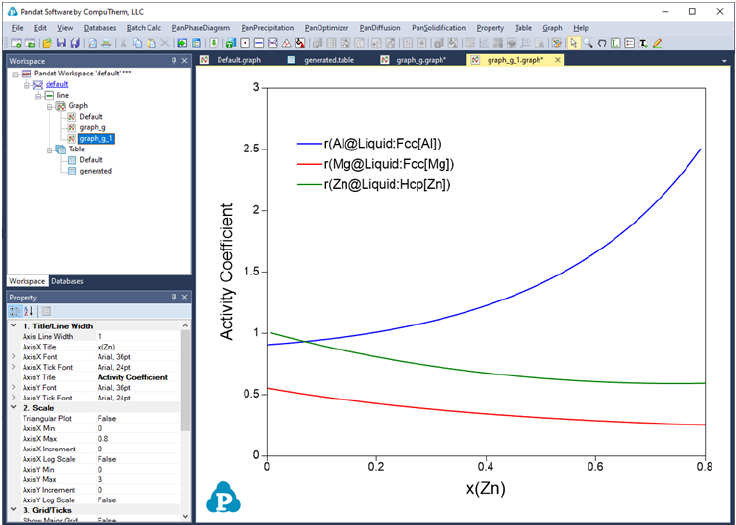

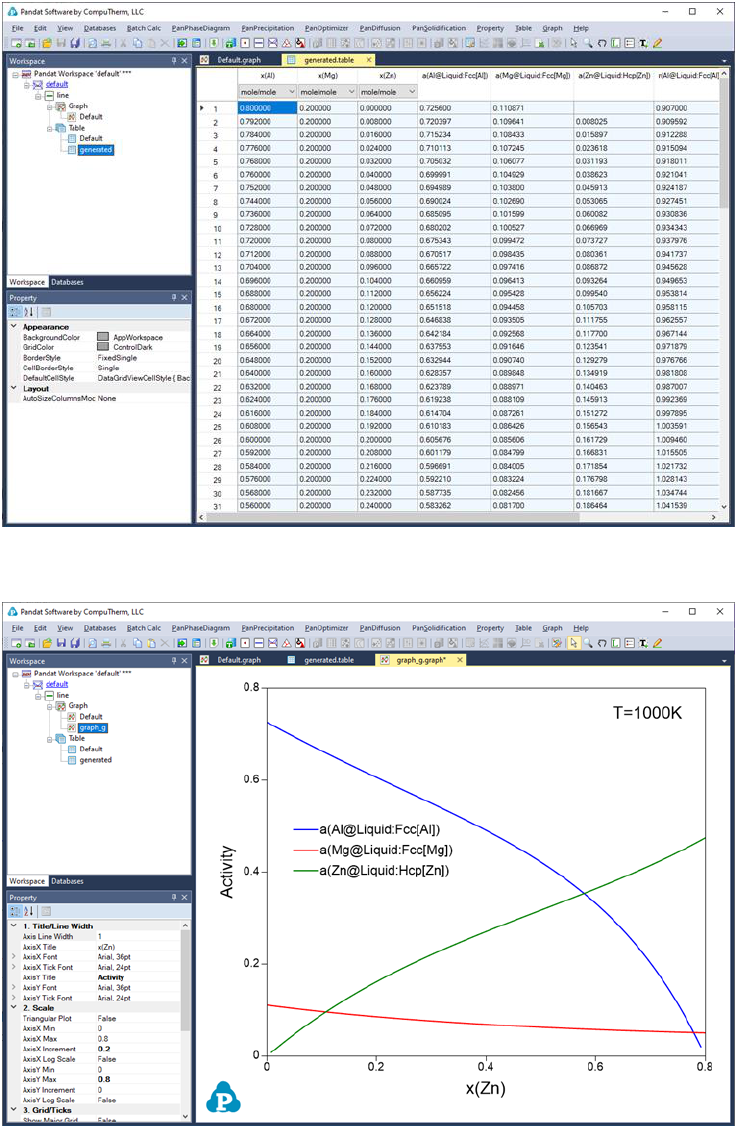

Figure 3.50 to Figure 3.53 show the screen images for creating a table of

activity and activity coefficient from a line calculation result at 1000K in the Al-

Mg-Zn ternary system. The two end points are at x(Mg)=0.2,x(Al)=0.8 and

86

Figure 3.51 Table of activity and activity coefficient

Figure 3.52 Graph of activity vs. x(Zn)

88

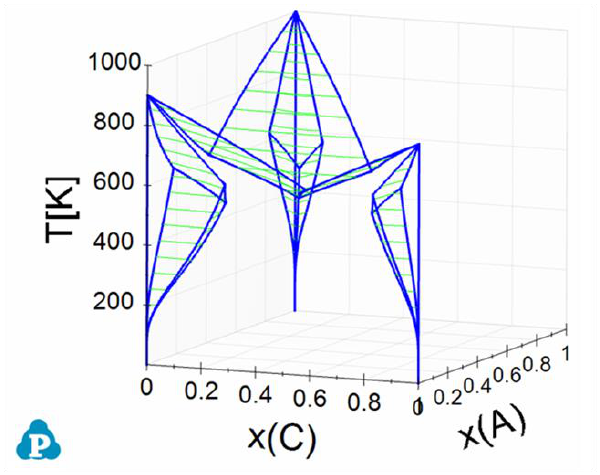

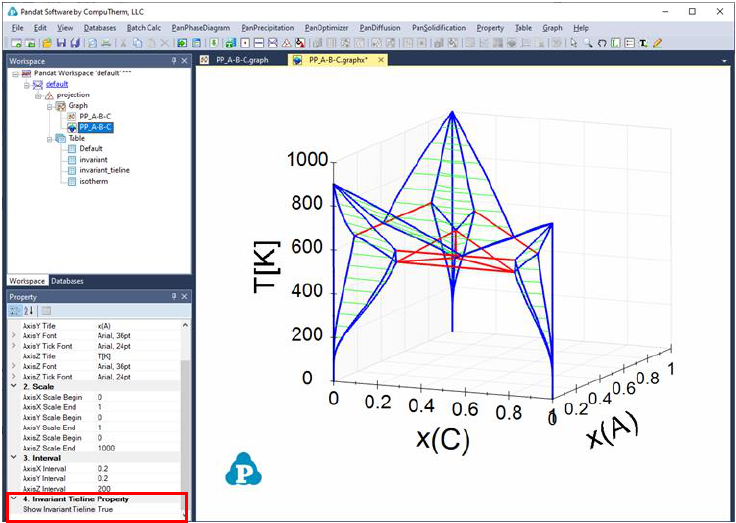

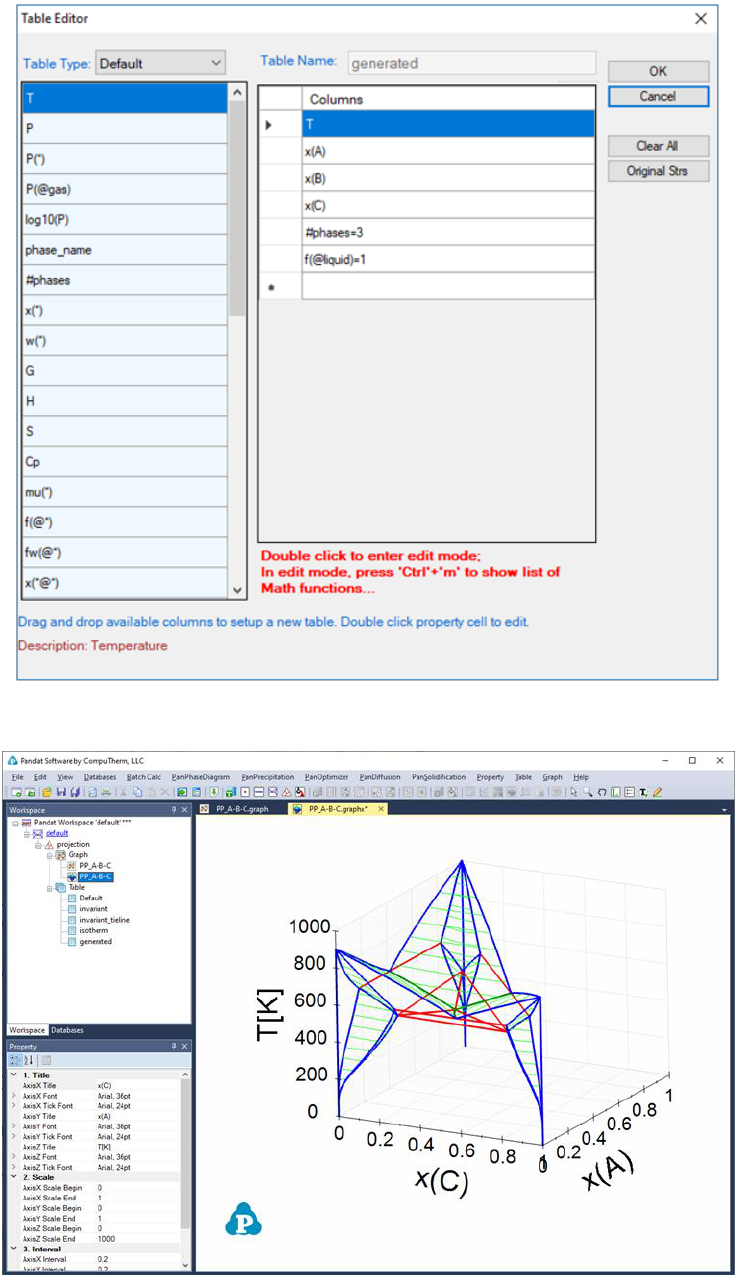

Figure 3.54 is a 3D ternary phase diagram calculated from the database file

“ABC.tdb” which is provided in the Pandat Examples. This system has three

binary eutectic reactions. To show the invariant tielines in these binaries, set

the “Show Invariant Tieline” in the Property window as “true”, then the

invariant lines will be plotted on it as shown in Figure 3.55.

Figure 3.54 3D phase projection of a simple ternary system with eutectic

reaction in every binary system

89

Figure 3.55 3D phase projection with three binary eutectic and one ternary

eutectic tielines shown as red

The ternary univariant lines (L+Bcc+Fcc, L+Bcc+Hcp, and L+Fcc+Hcp, magenta

color) connects these reactions can be highlighted as follows. First, create a

new table as shown in Figure 3.56. The purpose of the new table is to extract

the boundary line(s) that connect Liquid, and the other two solid phases, and

the fraction of Liquid on this boundary line is 1. After the table is created,

select this new table in the Explore window, and drag x(C) from the Property

window to the Main Display window, and drop it as the x-axis; press “Ctrl” and

then drag x(A) from the Property window to the Main Display window, and drop

it as the y-axis; press “Shift” and then drag T from the Property window to the

Main Display window, and drop it as the z-axis. This line showing the gradually

change from the peritectic reaction to the eutectic reaction is then highlighted

(green color), as shown in Figure 3.57.

90

Figure 3.56 Create a new table to extract the ternary univariant lines

91

Figure 3.57 The ternary univariant lines (green lines) connecting the two

invariant reactions in the two binaries

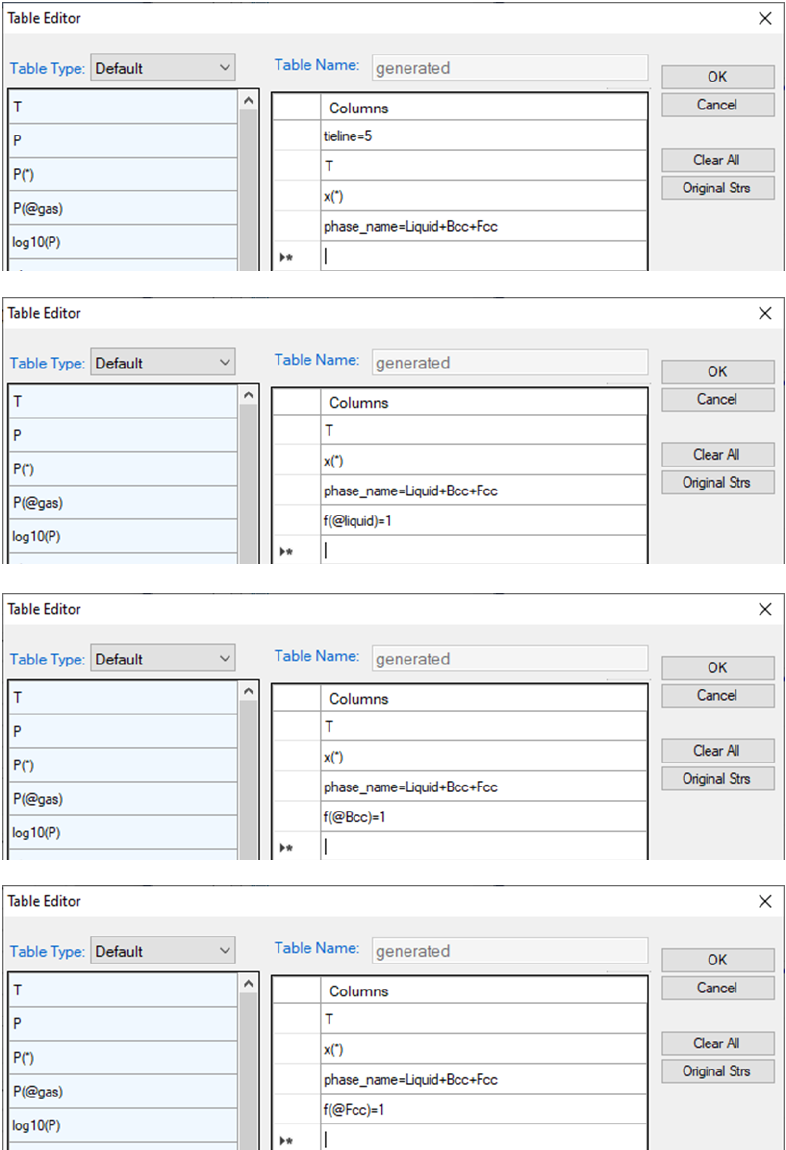

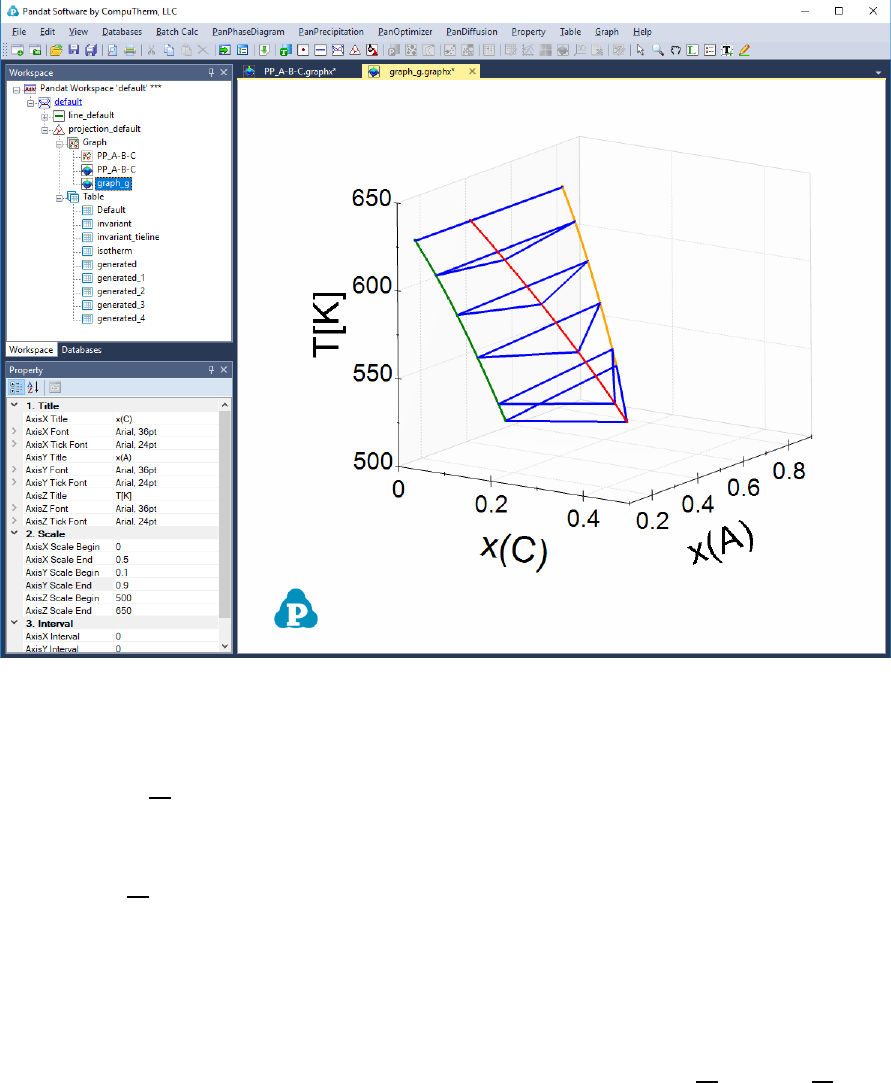

Figure 3.58 shows how to create 4 new tables to plot the 3D diagram in Figure

3.59, which shows the ternary three-phase equilibrium tie-triangle volume. The

4 tables include a set of the tie-triangles by setting its density as "tieline=5"

and the phase lines for the liquid, Bcc, Fcc phases by setting the fraction of the

corresponding phase to be 1.

92

Figure 3.58 Create tables to extract tie-triangles and the three edges of the

three-phase volume.

93

Figure 3.59 3D diagram of the three-phase volume.

3.3.8.3 Numerical derivative

The derivative

can be calculated numerically from the two columns of Y and

Z. The operator for numerical derivative is “//”, double slashes. The numerical

derivative of

is written in the form of “Y//Z” as the column name. Only one

numerical derivative operator is allowed in one column. In other words, user

cannot type in “Y//Z//X”.The derivative “Y//Z” will be parsed into three

columns in the new table: “Y”, “Z” and “Y//Z”, which makes it easy for the user

to view the original data set “Y”, “Z” and choose to plot either

vs Z or

vs Y.

The example given here is to find the “effective heat capacity” of the system

during solidification (H_tot//T). A system of Al-Mg-Zn is chosen and the

composition is shown in Figure 3.60. After Scheil simulation is done, a new

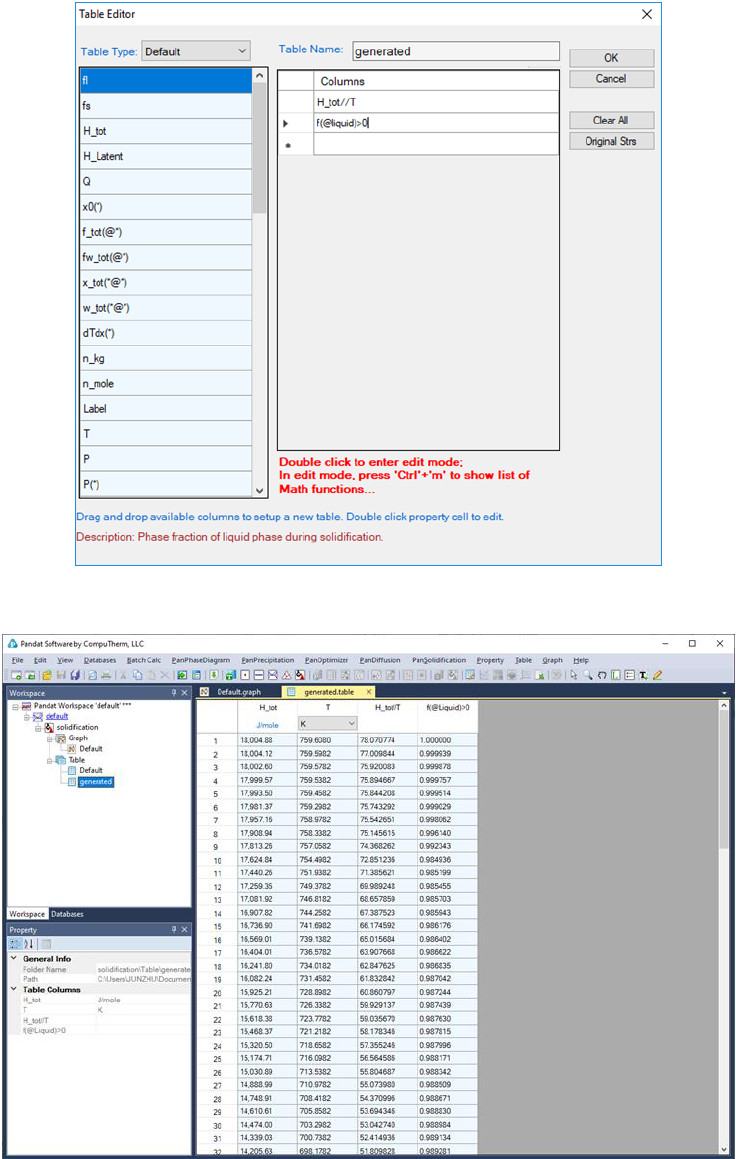

table is created with the definition of the column names shown in Figure 3.61.

94

Figure 3.62 is the newly generated table. Select the columns “T” and

“H_tot//T”, we have the

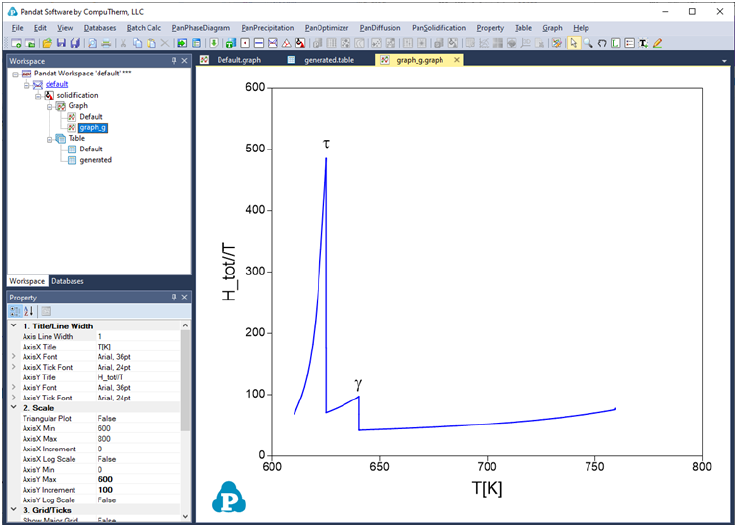

vs T diagram as in Figure 3.63. This diagram

shows the effective heat capacity change during the solidification by Scheil

simulation. There are two peaks in Figure 3.63, which represent roughly the

phase transformation from liquid to Hcp+γ and that from liquid to Hcp+,

respectively.

Figure 3.60 Solidification simulation condition.

95

Figure 3.61 Create a table for the numerical derivative of H_tot w.r.t. T.

Figure 3.62 The table for the numerical derivative of H_tot w.r.t. T.

96

Figure 3.63 plot of effective heat capacity change during the solidification

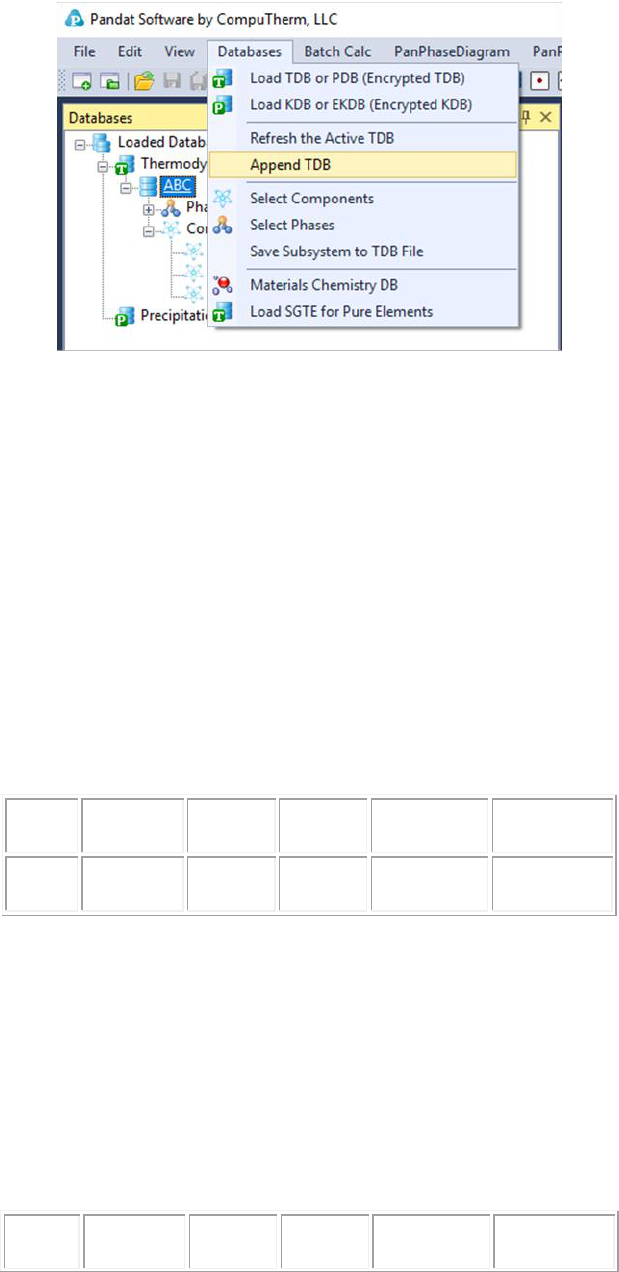

3.3.9 Append Database

On top of the original database (*.tdb or *.pdb) loaded from Pandat GUI, user

can append a custom-made database (*.tdb) by select the Append TDB

function from the Databases menu as shown in Figure 3.64.

Using this function, user can (1) replace the value of an existing parameter, (2)

add value to an existing parameter, (3) add new parameters to an existing

phase, (4) add new phases to the original database, and (5) add user-defined

properties. In the following, the hypothetical A-B system will be used as

example to explain the Append TDB function in detail.

97

Figure 3.64 Append TDB function under the Databases menu

3.3.9.1 Replace the Value of an Existing Parameter

In this example, we are going to replace the interaction parameter of the liquid

phase: G(Liquid,A,B;0) within the original AB_original.tdb database. Load the

AB_original.tdb from the Databases menu by selecting the Load TDB or PDB

function. The interaction parameter of G(Liquid,A,B;0) described in the original

database is expressed as:

Parameter G(Liquid,A,B;0) 298 3000; 6000 N !

In the TDB Viewer, one can see the original value of G(Liquid,A,B;0)=3000.

Name

Property

x-Term

x-order

Parameter

T-limit (K)

L

(A,B)

0

3000

6000

In the AB_replace parameter.tdb, only the interaction parameter for

G(Liquid,A,B;0) is defined, but with a different value:

Parameter G(Liquid,A,B;0) 298 -2000; 6000 N !

Load the AB_replace parameter.tdb via the Append TDB function, one can see

from the TDB Viewer that the interaction parameter of G(Liquid,A,B;0) is

replaced with the value (-2000) from the appended database.

Name

Property

x-Term

x-order

Parameter

T-limit (K)

98

Liquid

L

(A,B)

0

-2000

6000

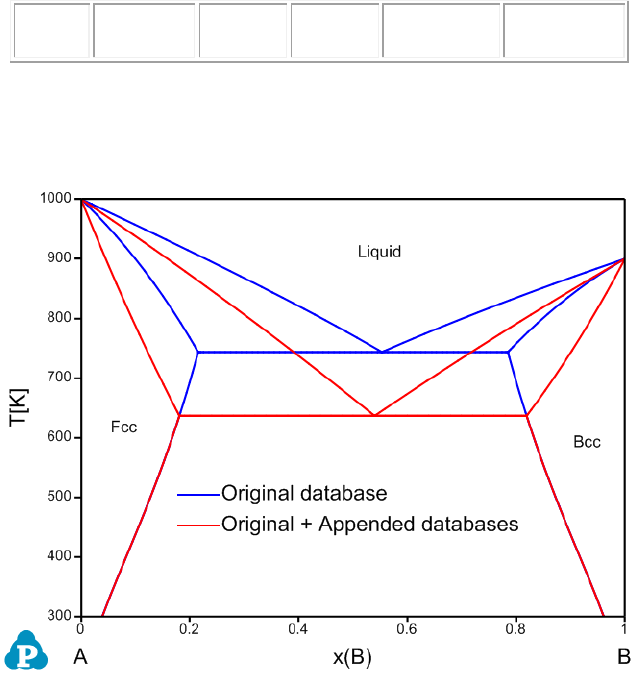

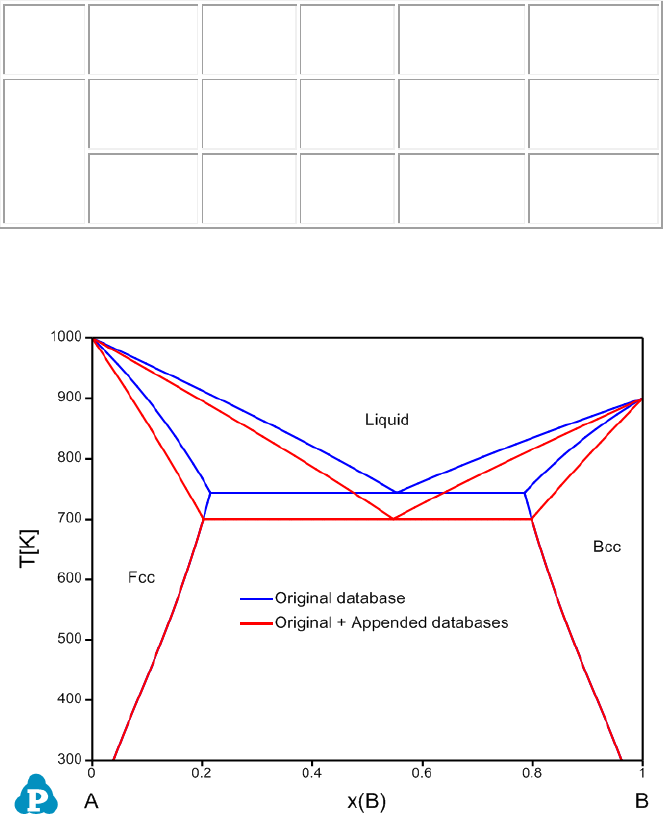

The calculated phase diagrams using both original database and original +

appended databases are shown in Figure 3.65.

Figure 3.65 Calculated A-B phase diagram using both original database and

original + appended databases

3.3.9.2 Add Value to an Existing Parameter

In this example, we are going to modify the interaction parameter of the liquid

phase G(Liquid,A,B;0) within the original AB_original.tdb database by adding a

value to it. As shown in the AB_modify parameter.tdb, the interaction

parameter is expressed as GG(Liquid,A,B;0), which means adding this

assigned value to the original value rather than replacing it.

Parameter GG(Liquid,A,B;0) 298 -2000; 6000 N !

As shown in the above section 3.3.9.1, the original value of the G(Liquid,A,B;0)

interaction parameter is +3000. When we append the AB_modify parameter.tdb

to the original database, the value of -2000 will be added to the original value

+3000 for the G(Liquid,A,B;0) interaction parameter. As shown in the TDB

viewer below, one extra term “GG” is listed. For this case, the total value of the

99

interaction parameter of G(Liquid,A,B;0) will be modified to be 3000 + (-2000) =

+1000.

Name

Property

x-Term

x-order

Parameter

T-limit (K)

Liquid

L

(A,B)

0

3000

6000

GG

(A,B)

0

-2000

6000

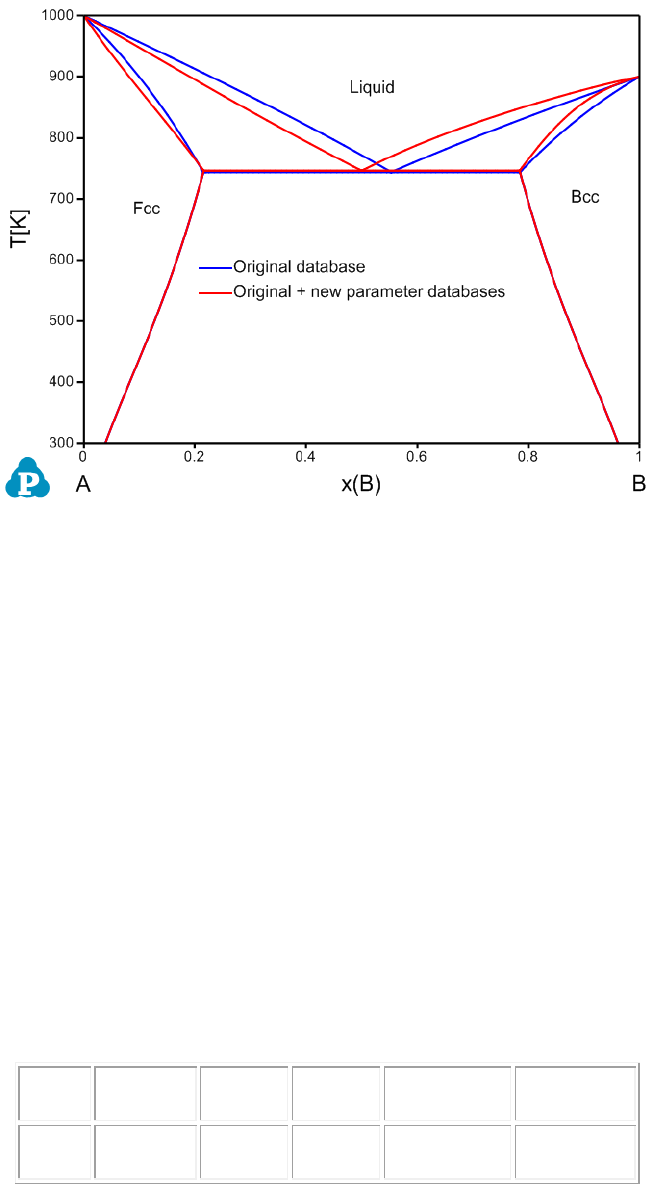

The calculated phase diagrams using both original database and original +

appended databases are shown in Figure 3.66.

Figure 3.66 Calculated A-B phase diagram using both original database and

original + appended databases with adjusted parameters

Note that, the Append TDB function allows user to append only one database

to the original database. When user wants to append another database to the

original database, the previously appended database will need to be removed

first. Pandat

TM

will notify the user as shown in Figure 3.67 and user need to

click Yes to confirm.

100

Figure 3.67 Append database confirmation

3.3.9.3 Add New Parameter to an Existing Phase

In addition to replace or modify the existing parameters for an existing phase in

the original database, one can also add new parameters to this phase. In the

AB_Original.tdb database, there is only one interaction parameter for the

Liquid phase G(Liquid,A,B;0). Using the Append TDB function, we can add

more interaction parameters to the Liquid phase. As shown in the AB_new

parameter.tdb, another interaction parameter for the liquid phase,

G(Liquid,A,B;1), is given as:

Parameter G(Liquid,A,B;1) 298 -2000; 6000 N !

Load the original AB_original.tdb and then load the AB_new parameter.tdb via

the Append TDB function. As shown in the TDB viewer, the new interaction

parameter (x-order value is 1) is added.

Name

Property

x-Term

x-order

Parameter

T-limit (K)

Liquid

L

(A,B)

0

3000

6000

L

(A,B)

1

-2000

6000

The calculated phase diagrams using both original database and original +

appended databases are shown in Figure 3.68.

101

Figure 3.68 Calculated A-B phase diagram using both original database and

original + appended databases with new parameters

3.3.9.4 Add New Phases to the Original Database

In addition to modify the parameters for existing phases within the original

database, one can also add new phases via the Append TDB function. A new

phase AB is introduced in the AB_new phase.tdb, which is described as:

Phase AB % 2 0.5 0.5 !

Constituent AB :A:B:!

Parameter G(AB,A:B;0) 298.15 -10000+6*T; 6000 N !

Load the AB_original.tdb first and then load the AB_new phase.tdb via the

Append TDB function. As shown in the TDB Viewer, a new AB phase is

introduced.

Name

Property

x-Term

x-order

Parameter

T-limit (K)

AB

L0

(A)(B)

0

-10000+6*T

6000

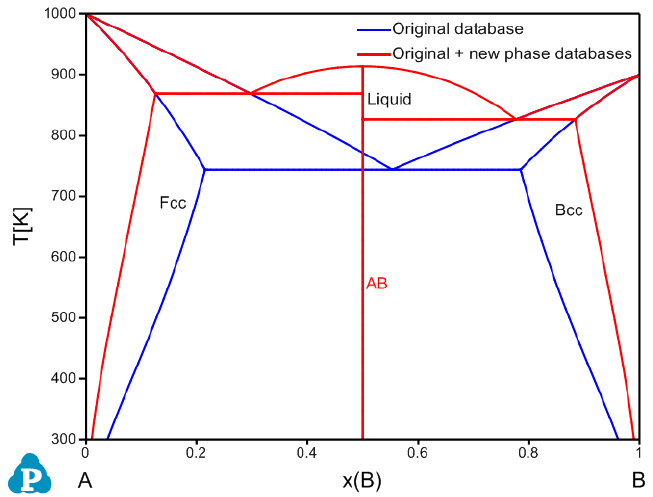

The calculated phase diagrams using both original database and original +

appended databases are shown in Figure 3.69.

102

Figure 3.69 Calculated A-B phase diagram using both original database and

original + appended databases with new phase

3.3.9.5 Add User-defined Properties to the Original Database

As is well known, the CALPHAD method has now been used to describe various

types of phase properties in addition to thermodynamic properties. Mobility

databases, molar volume databases and other thermo-physical property

databases can be developed via similar route as that of developing a

thermodynamic database. The Append TDB function allows a user to add

user-defined properties to an original database. In this example, we add molar

volume to AB_Original.tdb via the Append TDB function. The molar volume

parameters of A and B within the Bcc, Fcc, and Liquid phases are described in

the AB_property.tdb database as listed below:

Parameter Vm(Bcc,A;0) 298.15 +7.4e-6*exp(1e-6*T); 3000 N !

Parameter Vm(Bcc,B;0) 298.15 +8.4e-6*exp(1e-6*T); 3000 N !

Parameter Vm(Fcc,A;0) 298.15 +7.0e-6*exp(1e-6*T); 3000 N !

Parameter Vm(Fcc,B;0) 298.15 +8.0e-6*exp(1e-6*T); 3000 N !

Parameter Vm(Liquid,A;0) 298.15 +8.0e-6*exp(1e-6*T); 3000 N !

103

Parameter Vm(Liquid,B;0) 298.15 +9.0e-6*exp(1e-6*T); 3000 N !

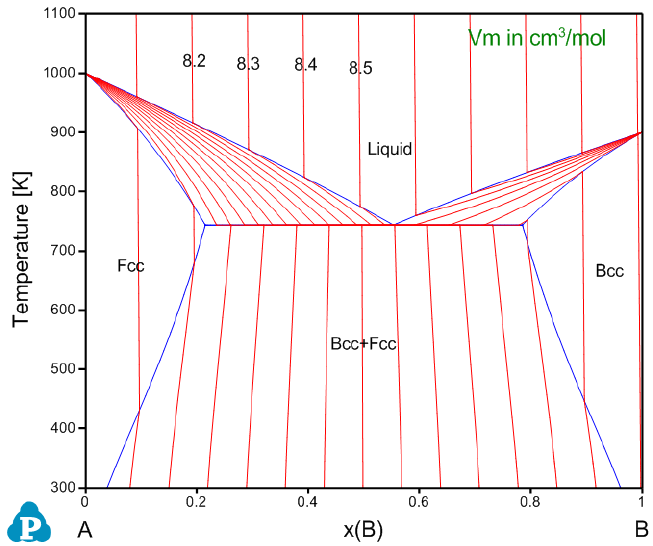

Load the original database AB_original.tdb and then append the

AB_property.tdb database via the Append TDB function. The currently

combined AB_original + AB_property database enables us to calculate molar

volume of the A-B binary system in addition to the phase diagram. The molar

volume contour lines are shown in Figure 3.70 (refer to Section 3.3.5 for

calculating contour diagrams). Moreover, density and linear thermal expansion

coefficient can also be calculated with this AB_original + AB_property database.

Please note that, various types of user-defined properties including but not

limited to atomic mobility, molar volume, viscosity, surface tension can all be

combined with the original thermodynamic database via the Append TDB

function.

Figure 3.70 Calculated A-B phase diagram using both original database and

original + appended databases with specific property

104

3.3.10 User-defined Property

This section is an extension of the above Append database section to develop

and add user-defined-property database to the original database. Pandat allows

user to define any property of a phase in a format similar to that of the Gibbs

energy describing a disordered solution phase. Let U be the user-defined

property and it is expressed as:

1

1 1 1

()

c c c

o k k

i i i j i j ij

i i j i k

U xU x x x x L

−

= = = +

= + −

where

i

x

is the molar fraction of component i and

0

i

U

is the property of the pure

component i,

k

ij

L

is the k

th

order interaction parameter between components i

and j.

User can also define special properties associated with the properties of phases

in the original database. Any phase property available from Pandat Table can

be used for user-defined property, such as G, H, mu, and ThF. However, the

star symbol in a property, like mu(*), cannot be used. User may refer to

section 8 for more properties in detail.

3.3.11 Advanced Features

In this section, we are going to cover some advanced features of the

PanPhaseDiagram module.

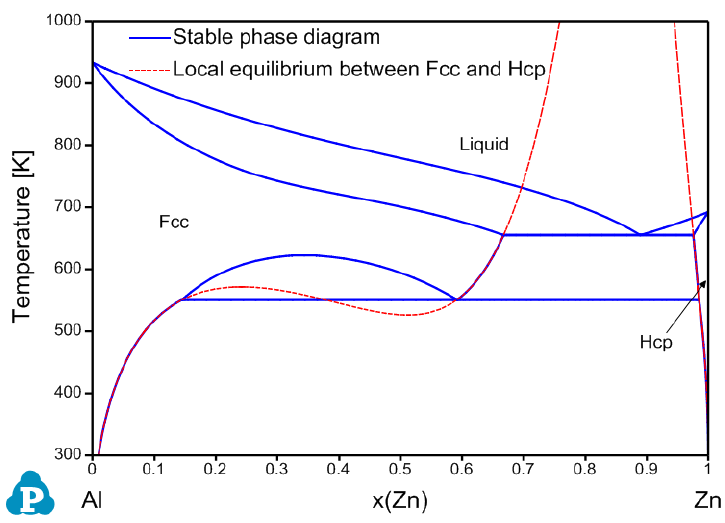

3.3.11.1 Local Equilibrium

In default, Pandat always calculates global stable phase equilibria. Even some

phases are suspended, the calculated phase equilibria are still global stable

ones for those “Entered” phases. The current version of Pandat enables us to

calculate a “real” local equilibrium. The Al-Zn binary system is used as an

example to demonstrate how to calculate the local phase equilibrium between

the Fcc and Hcp phases. Note that, there is not GUI for the local equilibrium

function and user has to run it through the batch file (.pbfx).

105

As shown below, a point with initial values needs to be defined in the batch file.

<point>

<statespace>

T value="500"/>

<P value="1"/>

<n component="Al" value="0.5"/>

<n component="Zn" value="0.5"/>

</statespace>

<initial_value>

<mu species="Al" value="-16000" />

<mu species="Zn" value="-22000" />

<phase_point phase_name="Fcc">

<y species="Al" sublattice="1" value="0.9" />

<y species="Zn" sublattice="1" value="0.1" />

</phase_point>

<phase_point phase_name="Hcp">

<y species="Al" sublattice="1" value="0.01" />

<y species="Zn" sublattice="1" value="0.99" />

</phase_point>

</initial_value>

</point>

In addition to the point with initial values, equilibrium type needs to be set as

“local” (as shown below)

<condition>

<equilibrium_type type="local"/>

106

</condition>

Figure 3.71 is the calculated stable Al-Zn binary phase diagram with the local-

equilibrium between Fcc and Hcp phases.

Figure 3.71 Calculated Al-Zn stable phase diagram with local-equilibrium

between Fcc and Hcp phases

3.3.11.2 Hessian matrix of Gibbs energy

Pandat can calculate the determinant of Hessian matrix of Gibbs energy of a

phase and the eigenvalues and eigenvectors of the Hessian matrix.

Since there is one dependent molar fraction for the molar fraction

variables

, one of the components is selected as the dependent one.

Without loss of generality,

is selected as the one, i.e., the last component is

considered as the solvent. Then, the second derivatives of Gibbs free energy of

a phase form the Hessian matrix, which is an

symmetrical

matrix.

107

Its determinant is given by

The determinant of Hessian matrix for phase f is available from “HSN(@f)”. The

value of “HSN(@f)” is independent of the selection of solvent component.

A Hessian matrix has real eigenvectors and each eigenvalue has a

corresponding eigenvector. The eigenvalues and their eigenvectors are available

from “eVal(#*@f)” and “HSN(*#*@f)”. Above Hessian matrix has eigenvalues

of “eVal(#1@f)”, eVal(#2@f)”, ,“eVal(#n-1@f)”. Each eigenvalue has an

eigenvector. For example, eVal(#1@f) has a eigenvector of (eVec(C

1

#1@f),

eVec(C

2

#1@f), , eVec(C

n-1

#1@f)), where C

k

is the name of the k

th

component.

108

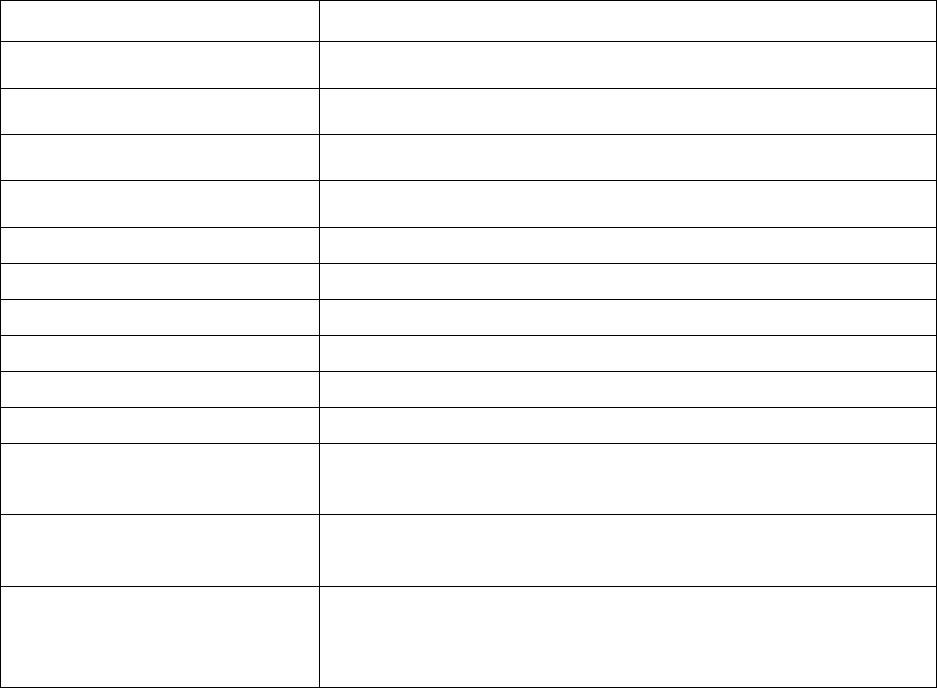

Table 3.1 Functions that can be used in database and Table operation

Function

Meaning

sin(x), cos(x), tan(x),

tan2(y,x)

Trigonometric functions. tan2(y,x)=tan(y/x)

asin(x), acos(x),

atan(x), atan2(y,x)

Arcus functions. atan2(y,x)= atan(y/x)

sinh(x), cosh(x),

tanh(x)

Hyperbolic functions

asinh(x), acosh(x),

atanh(x)

Arcus hyperbolic functions

Log2(x), log10(x), ln(x)

Logarithm functions to base 2, 10 or e

exp(x)

exponential function

abs(x)

absolute value

sqrt(x)

square root

rint(x)

round to integral value

sign(x)

sign function

HSN(@*)

determinant of Hessian matrix of Gibbs free energy of a

phase

eVal(#*@*)

eigenvalues of Hessian matrix of Gibbs free energy of a

phase. * after # represents the eigenvalue index

eVec(*#*@*)

eigenvectors for the eigenvalues of Hessian matrix of Gibbs

free energy of a phase. * before # represents the component

of eigenvector. * after # represents the eigenvalue index.

The “solvent” component can be defined while using “Thermodynamic Property”

calculation, or defined in Pandat Batch file. If “solvent” component is not

defined, Pandat will choose the first component (the smallest atomic number)

as the default “solvent” component.