CompuTherm is pleased to announce the new release of the Pandat

TM

software and databases version

2020. PanSolidification module, a new module of Pandat software is released. A number of new features

and improvements were also implemented in the PanPhaseDiagram, PanPrecipitation, PanDiffusion and

PanOptimizer modules in Pandat

TM

2020. This newsletter provides you a quick glance of the highlights.

Further details can be found in the User’s Guides of Pandat

TM

software and Thermodynamic Databases

Manual version 2020 at our website www.computherm.com.

New Release of Pandat

TM

Soware and Databases Version 2020

New Features and Improvements of Pandat

TM

2020

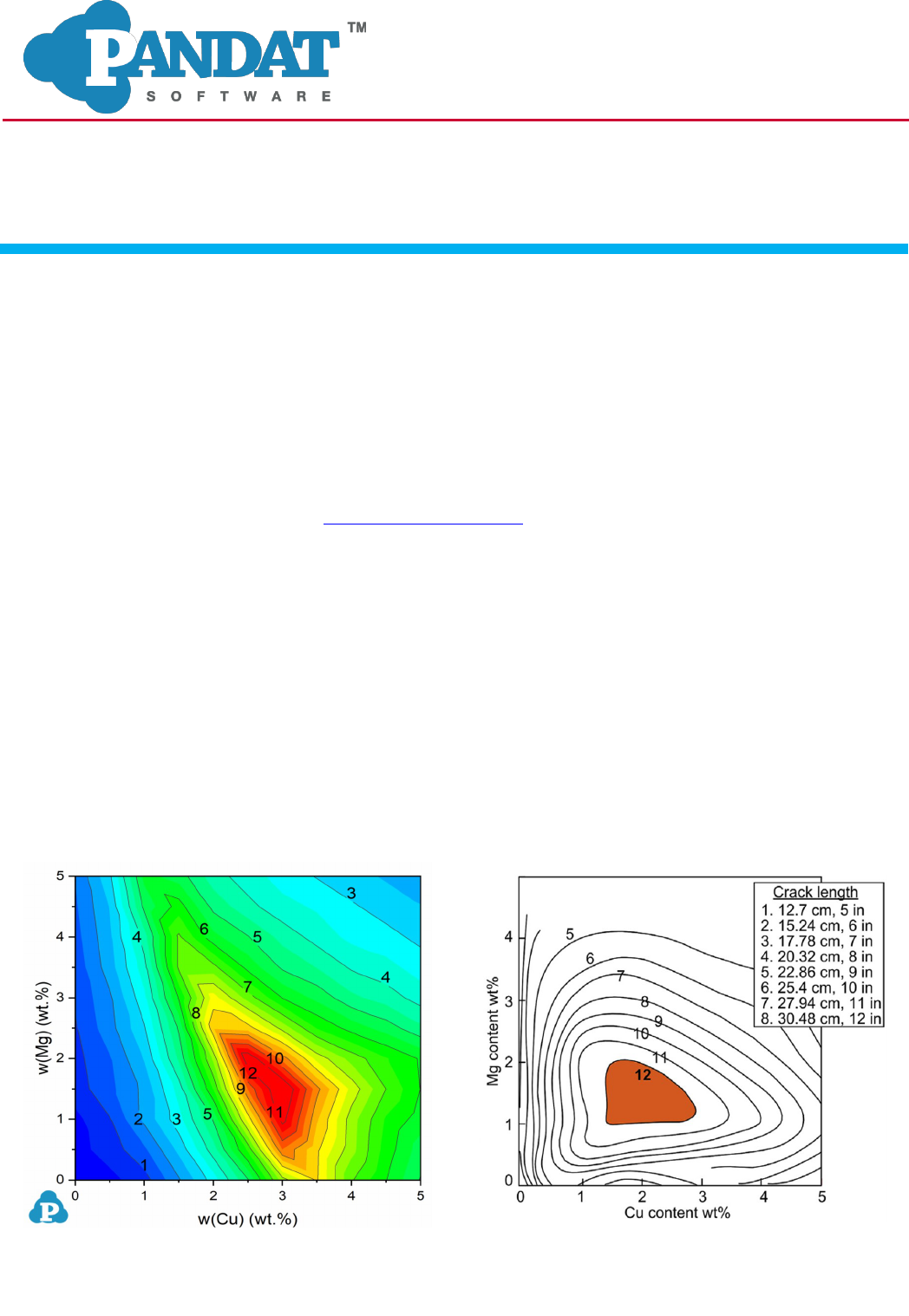

PanSolidification Module – This is a new module of Pandat

TM

software developed for the simulation of solidifi-

cation process. It is seamlessly integrated with the user-friendly Pandat

TM

Graphical User Interface (GUI) as well as

thermodynamic calculation engine, PanEngine. The major advantage of this module is that it takes into account of

back diffusion in the solid, undercooling effect and dendrite arm coarsening in the simulation. This module can be

used to simulate elemental distribution in the solid, secondary dendrite arm spacing and other properties during

solidification under given cooling rate. By combining with high-throughput calculation, it can also be used to sketch

hot cracking susceptibility maps. One such example is shown in Figure 1 for the Al-Cu-Mg system and compared

with the experimental observation as shown in Figure 2.

CompuTherm Newsletter

December 20, 2019

Page 1

CompuTherm, LLC

8401 Greenway Blvd.

Suite 248

Middleton, WI 53562

USA

Phone +1 (608) 203-8843

Fax +1 (608) 203-8045

Email info@computherm.com

Web www.computherm.com

Figure 1: Hot cracking susceptibility map with the cooling rate

of 20K/s for the Al-Cu-Mg ternary system

Figure 2: Experimental cracking susceptibility test results

J.W. Liu et al., Acta Mater., 125 (2017): 513-523

Page 2

New Features of PanPhaseDiagram, PanPrecipitation, PanDiffusion and PanOptimizer Modules

Eigenvalues, eigenvectors, and determinant of Hessian matrix of Gibbs free energy are implemented to allow

the calculation of spinodal lines of multi-component systems

A function is developed to obtain the liquidus and solidus slopes during solidification simulation

User-defined property capability is extended to allow user define system properties in the TDB file as a func-

tion of phase fractions in the format of Redlich-Kister polynomial

Contour line feature is extended and can now be applied to any properties including user-defined system

properties

New GUI for particle dissolution simulation is designed

High-throughput calculation is developed for PanSolidification module

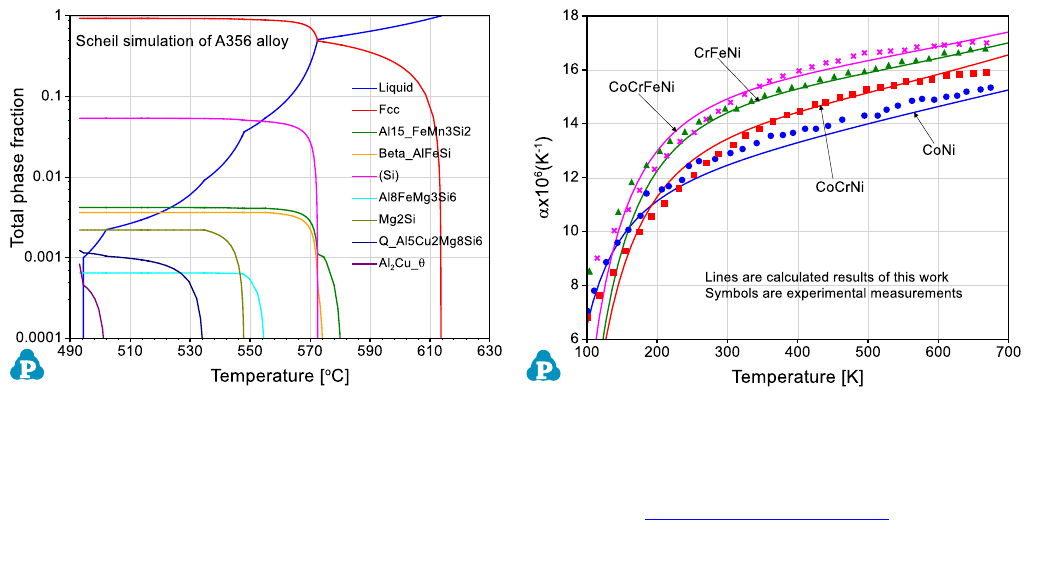

Log-scale graph and grid lines are available for the calculated properties as shown in Figure 3

Interfacial energy calculation can be performed at a given point or a series of points

Optimization can be performed for user-defined properties

High-throughput calculation function is enhanced with respect to both speed and reliability

Databases – Improvements were made for the existing thermodynamic databases: PanAl, PanCo, PanFe, PanMg,

PanMo, PanNb, PanNi, PanTi, PanTiAl, PanNoble, and PanHEA. Mobility databases and molar volume databases

are available for all the listed alloys. A mobility database can be integrated with the corresponding thermodynam-

ic database of an alloy system to simulate variety of diffusion-controlled processes, such as precipitation, diffusion

and solidification processes. A molar volume database can be integrated with the corresponding thermodynamic

database of an alloy system to simulate volume and density related properties. Figure 4 shows an example calcula-

tion which compares the calculated and measured linear thermal expansion coefficients for several alloy systems

using the combined thermodynamic and molar volume databases.

Figure 3: Simulated total phase fractions of the A356

alloy during solidification using the Scheil model

Figure 4: Comparison of the calculated and measured

linear thermal expansion coefficients

For more information, please visit our website: www.computherm.com